Mixed ligand cobalt (ii) complex and its preparation method and application

A technology of mixing ligands and complexes, applied in the direction of cobalt organic compounds, the size/direction of the magnetic field, etc., can solve problems such as limited, and achieve the effects of good solubility, high thermal stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of 1,2,4-triazole and 5-sulfoisophthalic acid mixed ligand cobalt(II) complex A:

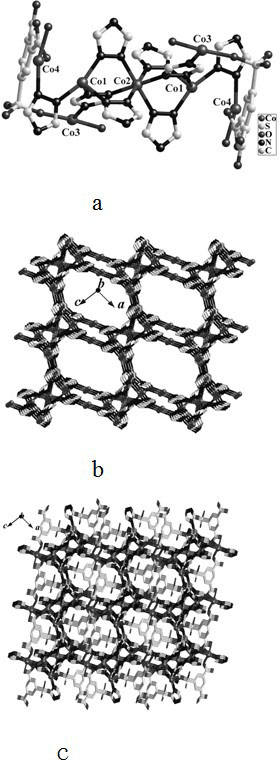

[0037] 1,2,4-triazole (0.2 mmol, 14.0 mg), m-benzene two Formic acid-5-sodium sulfonate (0.1 mmol, 27.0 mg) and cobalt nitrate hexahydrate (0.1 mmol, 29.0 mg) were dissolved in a mixed solution of twice distilled water (6.0 mL) and methanol (4.0 mL), and washed with three Ethylamine was used to adjust the pH to 6, and after stirring for a few minutes, it was sealed in a hydrothermal kettle. After incubating at 170° C. for 3 days, the temperature was programmed to cool down to room temperature to obtain a purple-red bulk single crystal, which was then washed with ethanol and dried in air. See figure 1 3D structure diagram.

Embodiment 2

[0039] Synthesis of 1,2,4-triazole and 5-sulfoisophthalic acid mixed ligand cobalt(II) complex B:

[0040] 1,2,4-Triazole (0.2 mmol, 14.0 mg), sodium 5-sulfoisophthalate (0.1 mmol, 27.0 mg) and cobalt nitrate hexahydrate (0.15 mmol, 44.0 mg) were dissolved In a mixed solution of double-distilled water (5.0 mL) and methanol (5.0 mL), adjust the pH to 7 with triethylamine, stir for several minutes, and seal it into a hydrothermal kettle. After being incubated at 165°C for 3 days, the temperature was programmed to cool down to room temperature to obtain a pink blocky single crystal, which was then washed with ethanol and dried, see figure 1 3D structure diagram.

Embodiment 3

[0042] Synthesis of 1,2,4-triazole and 5-sulfoisophthalic acid mixed ligand cobalt(II) complex C:

[0043] 1,2,4-triazole (0.2 mmol, 14.0 mg), m-benzene two Formic acid-5-sodium sulfonate (0.1 mmol, 27.0 mg) and cobalt nitrate hexahydrate (0.15 mmol, 44.0 mg) were dissolved in a mixed solution of twice distilled water (6.0 mL) and ethanol (4.0 mL), and washed with three Ethylamine was used to adjust the pH to 7, and after stirring for a few minutes, it was sealed in a hydrothermal kettle. After incubating at 160° C. for 3 days, the temperature was programmed to cool down to room temperature to obtain a pink bulk single crystal, which was then washed with ethanol and dried. See figure 1 3D structure diagram.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com