Phosphorus-free scale and corrosion inhibitors for circulating cooling water treatment

A circulating cooling water, phosphorus-free scale inhibition technology, applied in the field of scale and corrosion inhibitors, to achieve the effects of easy use, saving fresh water resources, and improving scale and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of non-phosphorous scale and corrosion inhibitor-1 for circulating cooling water treatment: 10% polyacrylic acid, 8% tannic acid, 15% polyaspartic acid, 5% borax, 16% octadecyl imidazole Phenol, 5% sodium gluconate, and 41% deionized water are placed in a container and stirred evenly at room temperature to obtain the non-phosphorus scale and corrosion inhibitor of the present invention.

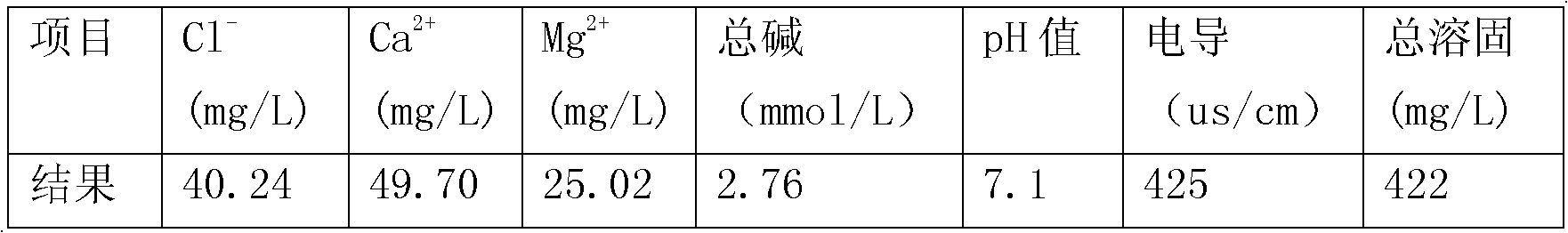

[0024] The phosphorus-free scale and corrosion inhibitor-1 was tested in the tap water of Tianjin, and the water quality is as follows:

[0025]

[0026] Add non-phosphorus scale and corrosion inhibitor-1 agent into the above water quality at 40ppm, when the concentration ratio reaches 3.8 times, the static relative scale inhibition rate is 98.45%; the uniform corrosion rate of A3 carbon steel in the rotating coupon test is 0.0663mm / a The uniform corrosion rate of H62 copper sheet is 0.0032mm / a; the result of dynamic simulation experiment is that the uniform corrosion ra...

Embodiment 2

[0028] Preparation of non-phosphorus scale and corrosion inhibitor-2 for circulating cooling water treatment: 15% polyacrylic acid, 5% tannic acid, 10% polyaspartic acid, 5% borax, 18% octadecyl imidazole Phenol, 4% sodium gluconate, and 43% deionized water are placed in a container and stirred evenly at room temperature to obtain the phosphorus-free scale and corrosion inhibitor of the present invention.

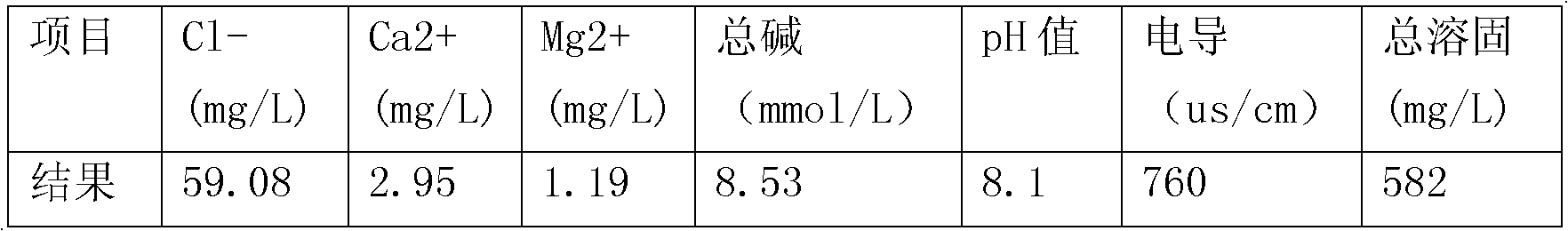

[0029] The agent was tested in the groundwater quality of Tianjin, and the water quality is as follows:

[0030]

[0031] Add the non-phosphorus scale and corrosion inhibitor-2 agent to the above water quality at 40ppm, when the concentration ratio reaches 3.8 times, the static relative scale inhibition rate is 98.45%; the uniform corrosion rate of A3 carbon steel in the rotating coupon test is 0.0663mm / a The uniform corrosion rate of H62 copper sheet is 0.0032mm / a; the result of dynamic simulation experiment is that the uniform corrosion rate of A3 carbon steel is 0.046...

Embodiment 3

[0033] Preparation of non-phosphorous scale and corrosion inhibitor-3 for circulating cooling water treatment: 12% polyacrylic acid, 18% tannic acid, 18% polyaspartic acid, 8% borax, 10% heptadecylimidazole Phosphate, 10% octadecyl imidazoline, 5% sodium gluconate, and 19% deionized water are placed in a container at room temperature and stirred evenly to obtain the phosphorus-free scale and corrosion inhibitor of the present invention.

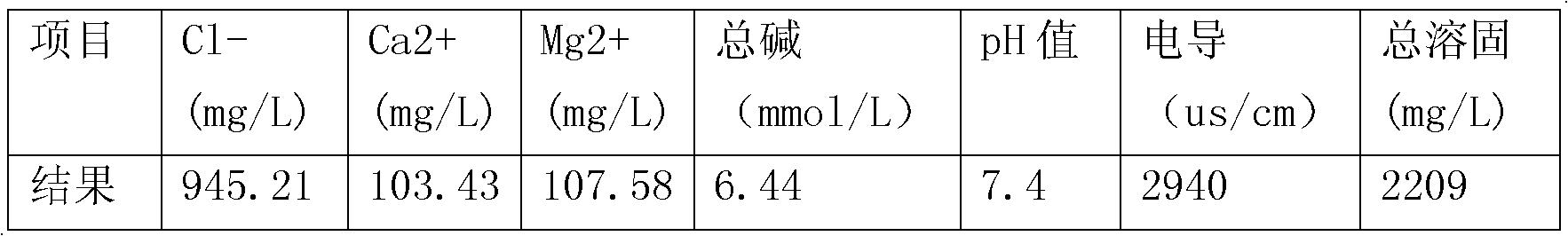

[0034] The phosphorus-free scale and corrosion inhibitor-2 was tested in the water quality of Haihe River in Tianjin. The water quality is as follows:

[0035]

[0036]Add the non-phosphorus scale and corrosion inhibitor-3 agent to the above water quality at 40ppm, when the concentration ratio reaches 3.2 times, the static relative scale inhibition rate is 98.10%; the uniform corrosion rate of A3 carbon steel in the rotating coupon test is 0.0883mm / a The uniform corrosion rate of H62 copper sheet is 0.0042mm / a; the result of dynamic simula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Uniform corrosion rate | aaaaa | aaaaa |

| Uniform corrosion rate | aaaaa | aaaaa |

| Uniform corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com