A kind of preparation method of two-dimensional porous silica nanosheet

A technology of porous silica and nano-silica, applied in the direction of silica, silicon oxide, nanotechnology, etc., to achieve high yield, wide application value, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

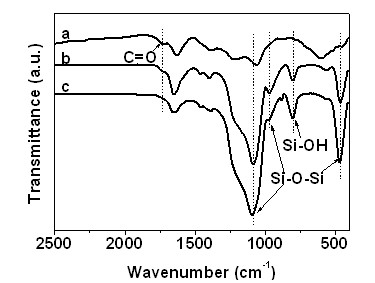

[0016] Step (1). With 10mg graphene oxide (for its infrared spectrum, see figure 2 Middle curve a), 50mg of tetraethyl orthosilicate, 10mg of ammonia water with a concentration of 30%, and 50g of mixed solvent were added to the reactor, and after ultrasonication for 10 minutes, stirring was carried out for 105 minutes to form a nano-silica supported graphene oxide solution ( The infrared spectrum of graphene oxide supported by nano-silica in solution is shown in figure 2 Middle curve b); the mixed solvent is a mixture of water and ethanol with a volume ratio of 1:5;

[0017] Step (2). After centrifuging the graphene oxide solution supported by nano-silica, pour off the supernatant, then add dehydrated alcohol equal to the volume of the supernatant that was poured out this time; centrifuge again, and pour off the supernatant 1. Add the same volume of absolute ethanol as the supernatant that was poured out this time; centrifuge for the third time, pour off the supernatant, ad...

Embodiment 2

[0021] Step (1). Add 100mg of graphene oxide, 1g of tetraethyl orthosilicate, 10g of ammonia water with a concentration of 10%, and 200g of mixed solvent into the reactor. After ultrasonication for 60 minutes, stir for 24 hours to form a nano-silica load. Graphene oxide solution; The mixed solvent is a mixed solution of water and ethanol with a volume ratio of 1:5;

[0022] Step (2). After centrifuging the graphene oxide solution supported by nano-silica, pour off the supernatant, then add dehydrated alcohol equal to the volume of the supernatant that was poured out this time; centrifuge again, and pour off the supernatant 1. Add the same volume of absolute ethanol as the supernatant that was poured out this time; centrifuge for the third time, pour off the supernatant, add absolute ethanol that is the same volume as the supernatant that was poured out this time; centrifuge for the fourth time , after discarding the supernatant, the centrifuged product was dissolved in water e...

Embodiment 3

[0026] Step (1). Add 20mg of graphene oxide, 400mg of tetraethyl orthosilicate, 200mg of ammonia water with a concentration of 20%, and 240g of mixed solvent into the reactor. After ultrasonication for 30 minutes, stir for 12 hours to form a nano-silica load. Graphene oxide solution; The mixed solvent is a mixed solution of water and ethanol with a volume ratio of 1:5;

[0027] Step (2). After centrifuging the graphene oxide solution supported by nano-silica, pour off the supernatant, then add dehydrated alcohol equal to the volume of the supernatant that was poured out this time; centrifuge again, and pour off the supernatant 1. Add the same volume of absolute ethanol as the supernatant that was poured out this time; centrifuge for the third time, pour off the supernatant, add absolute ethanol that is the same volume as the supernatant that was poured out this time; centrifuge for the fourth time , after pouring off the supernatant, the centrifuged product was dissolved in wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com