Method for producing white carbon black with fcc waste catalyst as raw material

A waste catalyst and white carbon black technology, applied in the direction of silicon oxide, silicon dioxide, chemical recovery, etc., can solve the problems of poor separation effect and high cost of electromagnetic equipment, and achieve the effects of cost reduction, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

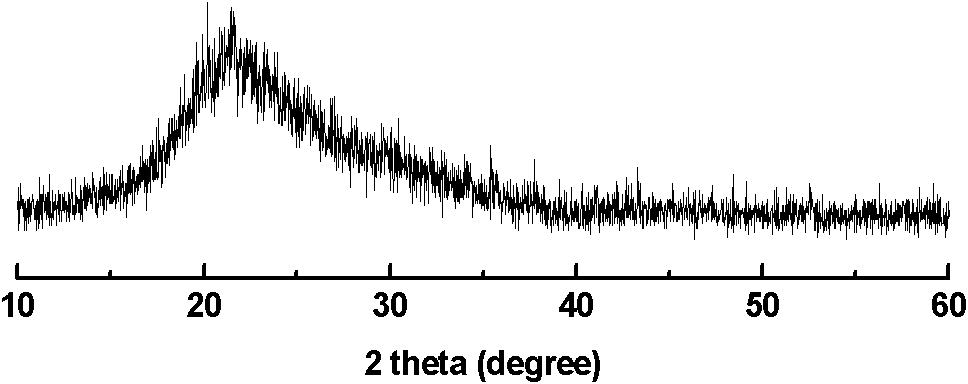

[0020] The spent FCC catalyst with a silicon dioxide content of 47.1% was used as a raw material, and the additive anhydrous sodium carbonate was added in a ratio of 1:1, and mechanically activated and reactively ground by a high-energy ball mill for 5 minutes. Calcined 30.0021g of the activated material at 700°C to obtain 23.2968g of the product, with a weight loss of about 22.35% after calcination; then took out 15g of the product and extracted it with water, the mass solid-liquid ratio was 1:5, the extraction time was 2 hours, and then filtered. The filtrate was gelled in a water bath at 70°C for 3 hours, washed three times, dried at 105°C for 3 hours, and crushed to obtain a white carbon black product. The XRD pattern of the product is attached figure 1 , indicating that the product is an amorphous structure. After testing, its main performance indicators are: silica content 98.6%, specific surface area about 250m 2 / g, DBP oil absorption value 220ml / 100g, PH about 6.5,...

Embodiment 2

[0022] The spent FCC catalyst with a silicon dioxide content of 47.1% was used as a raw material, and the additive anhydrous sodium carbonate was added in a ratio of 1:1, and the activation reaction was carried out by a high-energy ball mill for 5 minutes. The activated material was calcined at 750°C; then 15g was taken out and leached with water for 3h, and then filtered. The filtrate was gelled in a water bath at 70°C for 2 hours, washed 5 times, dried at 105°C for 3 hours, and crushed to obtain a white carbon black product. After testing, its main performance indicators are: silica content 99.0%, specific surface area about 300m 2 / g, DBP oil absorption value 230ml / 100g, PH about 6.5, loss on drying (110°C, 2h) 7%, loss on ignition (900°C, 2h) 9%, all in line with the relevant national standards for precipitated silica .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com