Intelligent mobile dry-mixed mortar instant mixing platform

A dry-mixed mortar, mobile technology, applied in mixing operation control, mixing plant, clay preparation device, etc., to achieve the effect of reducing construction and use costs, simplifying production processes, reducing production costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

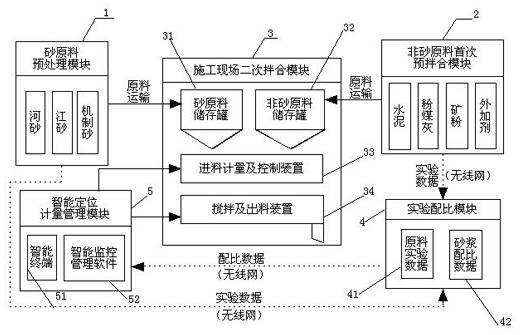

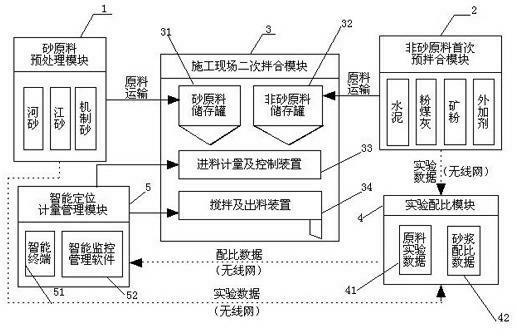

[0020] Depend on figure 1 The present invention shown includes a sand raw material pretreatment module 1, a non-sand raw material premixing module 2 for the first time, a construction site secondary mixing module 3, an experiment proportioning module 4, and an intelligent positioning measurement management module 5. The invention can solve the problems of high cost of dry-mixed mortar, repeated waste of energy and the like, and promotes the rapid development of the dry-mixed mortar industry.

[0021] The sand raw material pretreatment module 1 pretreats the sand raw material used in dry-mixed mortar. The type of sand raw material can be river sand, river sand, machine-made sand, etc. The pretreatment process includes screening and grading the sand. , Desilting, precipitation and other operations, during the precipitation treatment, the purpose of reducing the water content of the sand is achieved by drying or simply drying to reduce energy consumption. After the sand raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com