Method for machining oil seal shaft

A processing method and oil seal technology, which are applied in metal processing equipment, manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of not being able to meet the oil seal without oil leakage, and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

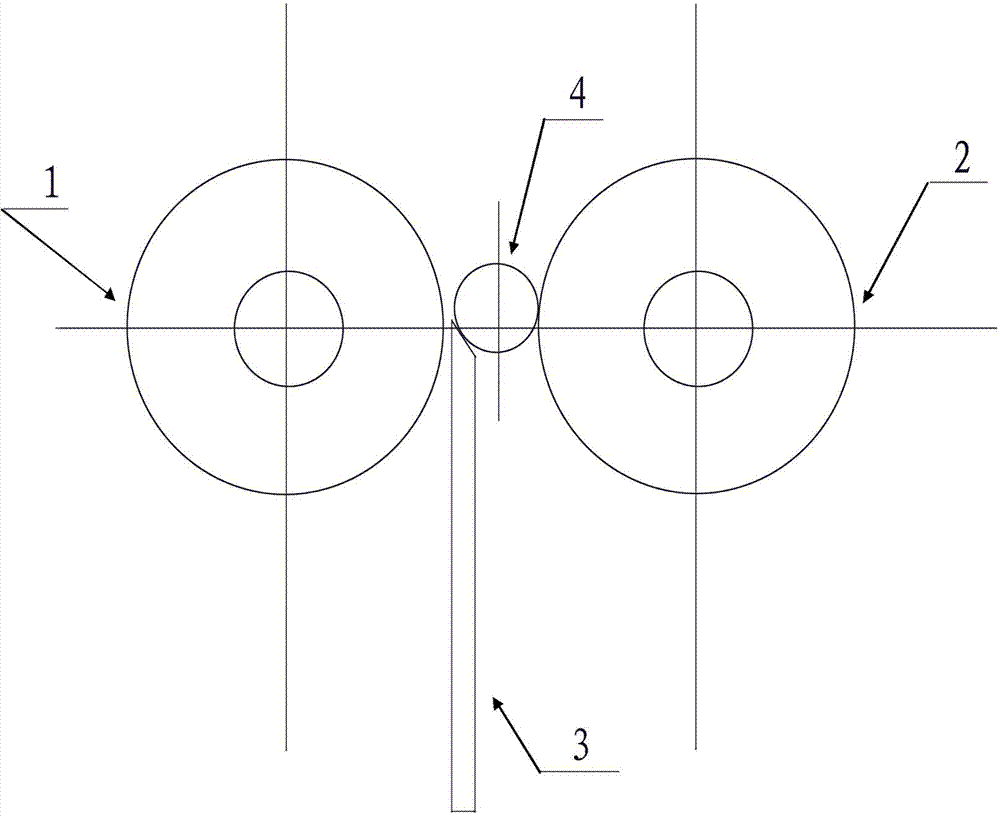

[0027] To refit the existing centerless grinder, first choose CBN grinding wheel (CBN140 / 170B100) as the centerless grinder grinding wheel 1, which meets the following requirements: roughness: Ra0.2~0.4 and Rz<4, and the grain direction produced after grinding should be parallel And perpendicular to the center line of the shaft, the grinding wheel is not easy to wear, and the thickness is equal to the axial length of the oil seal groove of the shaft. One side of the grinding wheel is provided with a guide wheel 2, the axes of the two are parallel, the axis of the guide wheel and the axis of the grinding wheel are on the same horizontal plane, and the distance between the grinding wheel and the guide wheel = diameter of the workpiece - depth of the oil seal groove. The axle of this guide wheel links to each other with the motor output shaft. A vertical supporting plate 3 is arranged between the emery wheel and the guide, and the supporting plate top surface is an inclined p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com