A kind of saline solution etching method of suede ZNO base film

A technology of thin film corrosion and salt solution, applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc., to achieve the effects of increased production and yield, significant light trapping effect, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Al-doped ZnO transparent conductive films were grown by magnetron sputtering. Using ammonium phosphate solution as the etching solution, the above-mentioned Al-doped ZnO transparent conductive film was corroded for 5 minutes by using ammonium phosphate solution with a mass concentration of 5%. Such as figure 1 shown.

Embodiment 2

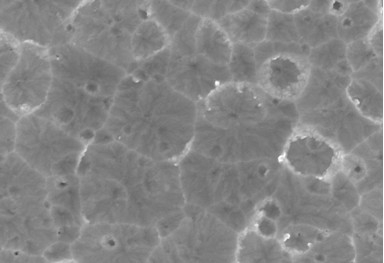

[0017] Al-doped ZnO transparent conductive films were grown by magnetron sputtering. Using ammonium sulfate solution as the etching solution, the above-mentioned Al-doped ZnO transparent conductive film was corroded for 1 min with ammonium sulfate solution with a mass concentration of 10%, and the textured ZnO-based film obtained was 14% at 550nm. Such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com