a low drag boat

A technology with low water resistance and bottom of the ship, which is applied in the direction of hull, ship construction, ship propulsion, etc. It can solve the problems of limited water supply, affecting ship speed, and affecting drainage speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

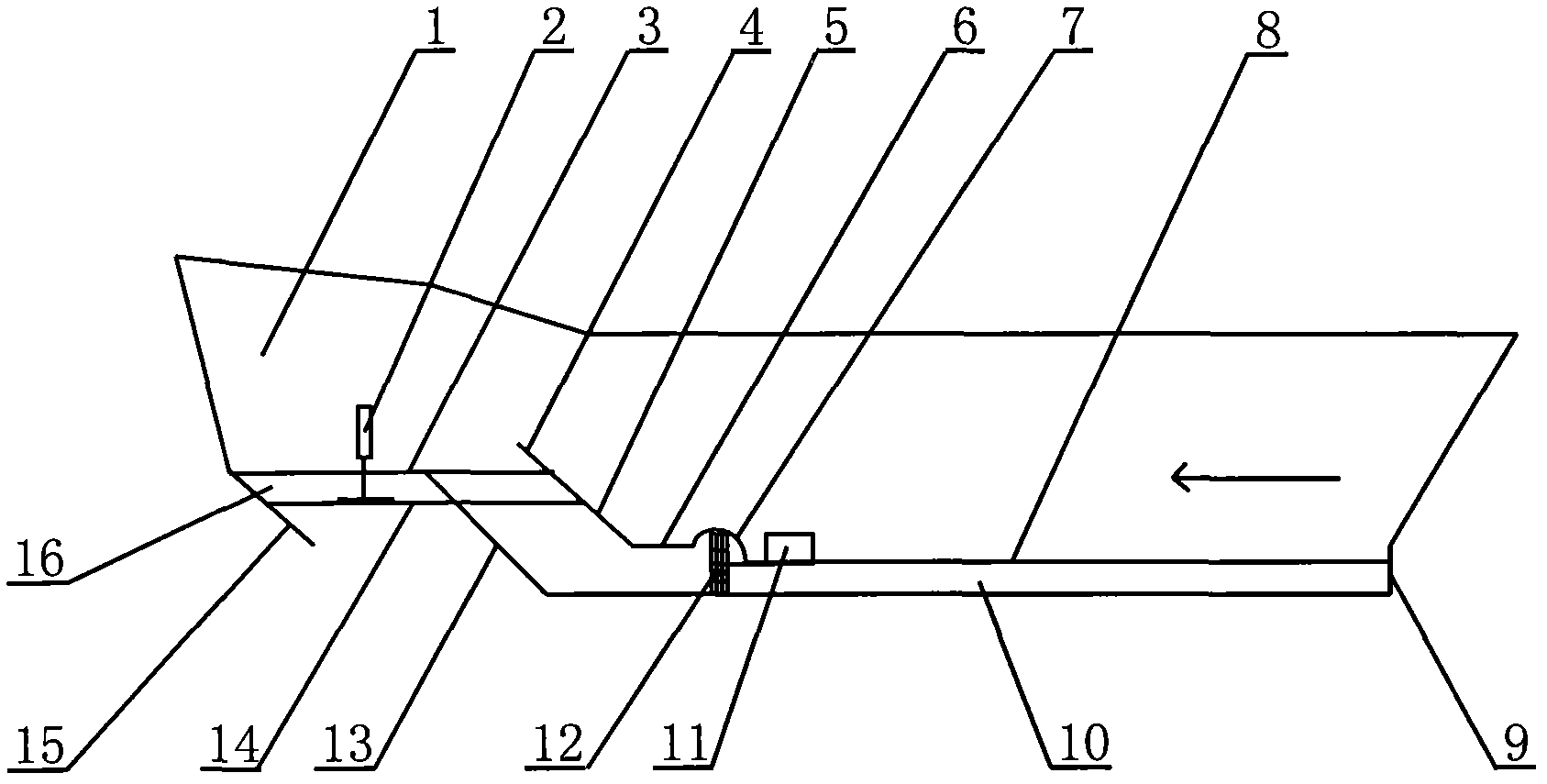

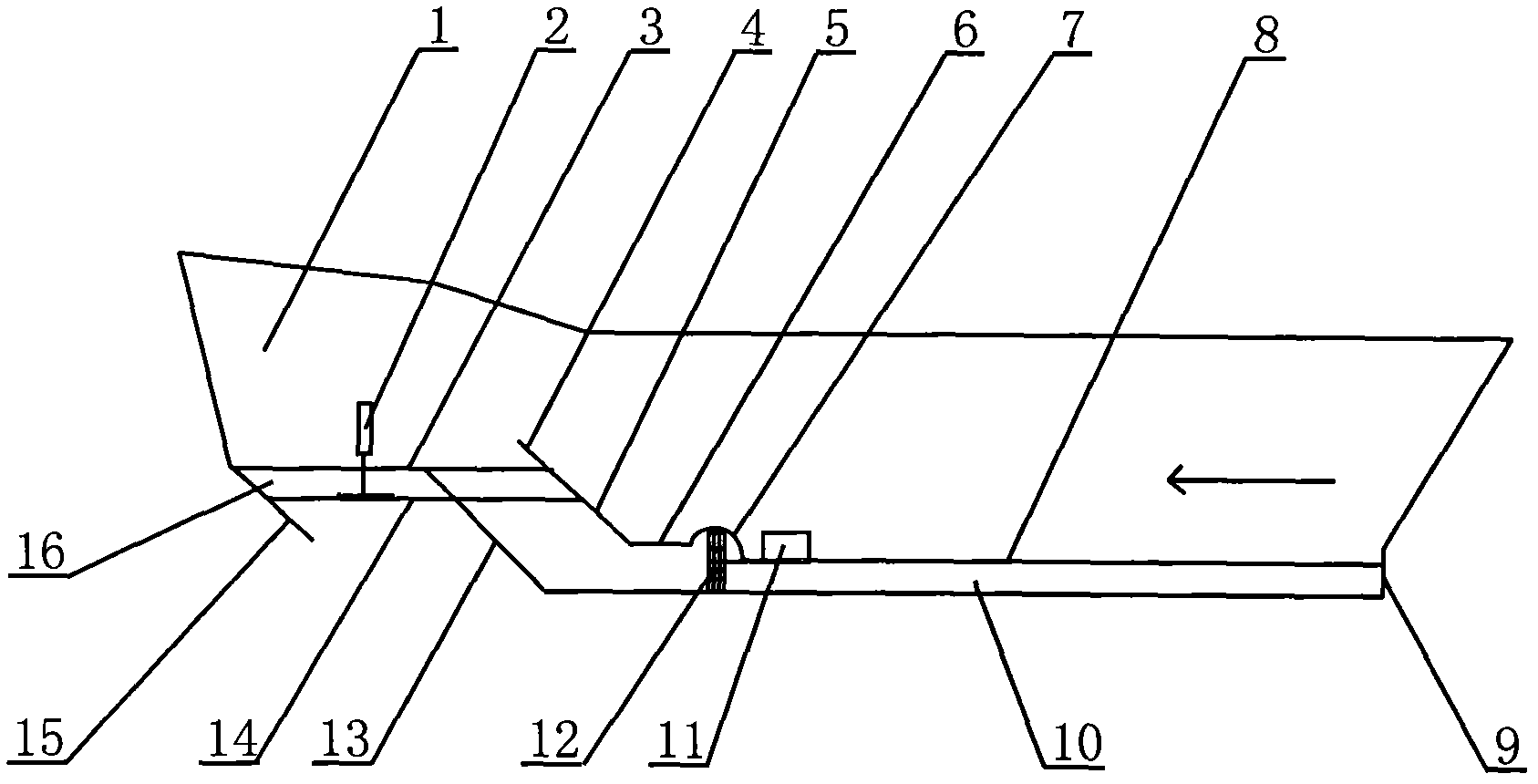

[0016] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0017] Such as figure 1 As shown, the present embodiment includes a hull 1 with a power machine 11, and also includes a speed-up compartment surrounded by the bottom of the ship and the speed-up bulkhead 10 located below the bottom of the ship. The speed-up chamber is only open at the front and rear ends. The bilges of the speed-up cabins are at the same level.

[0018] The bottom of the ship is sequentially connected end to end with a horizontal air-blocking section 3, a contraction section 5, a water entry section 6, an arched section 7, and a water outlet section 8, and each section has the same width, which is not less than that of the bottom of the ship. width. The bottom surfaces of the horizontal gas blocking section 3, the contraction section 5, the water entry section 6 and the water exit section 8 are all planes. The front end of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com