Tool changing device for changing tools on machine tool spindle and machine tool with the device

A tool changer and spindle technology, applied in the field of machine tools, can solve the problems of increased wear, high friction, space occupation, etc., and achieve the effect of simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

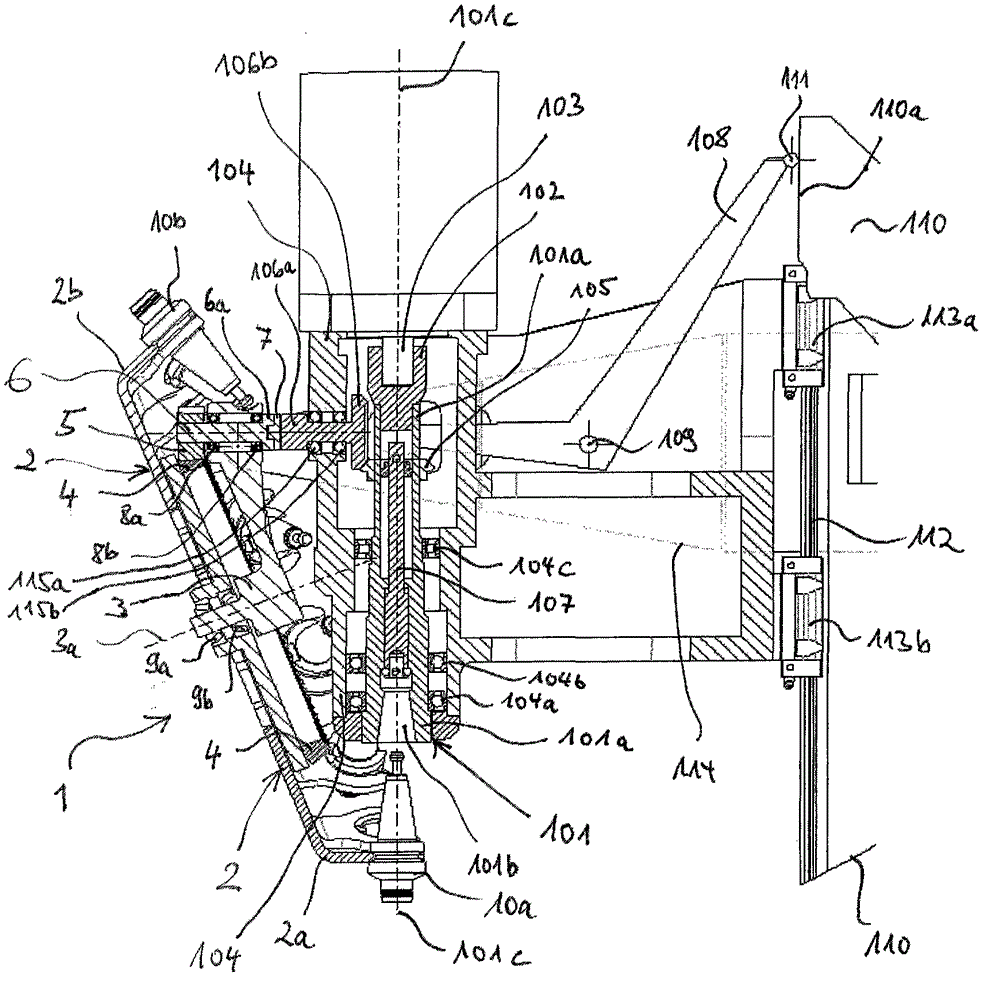

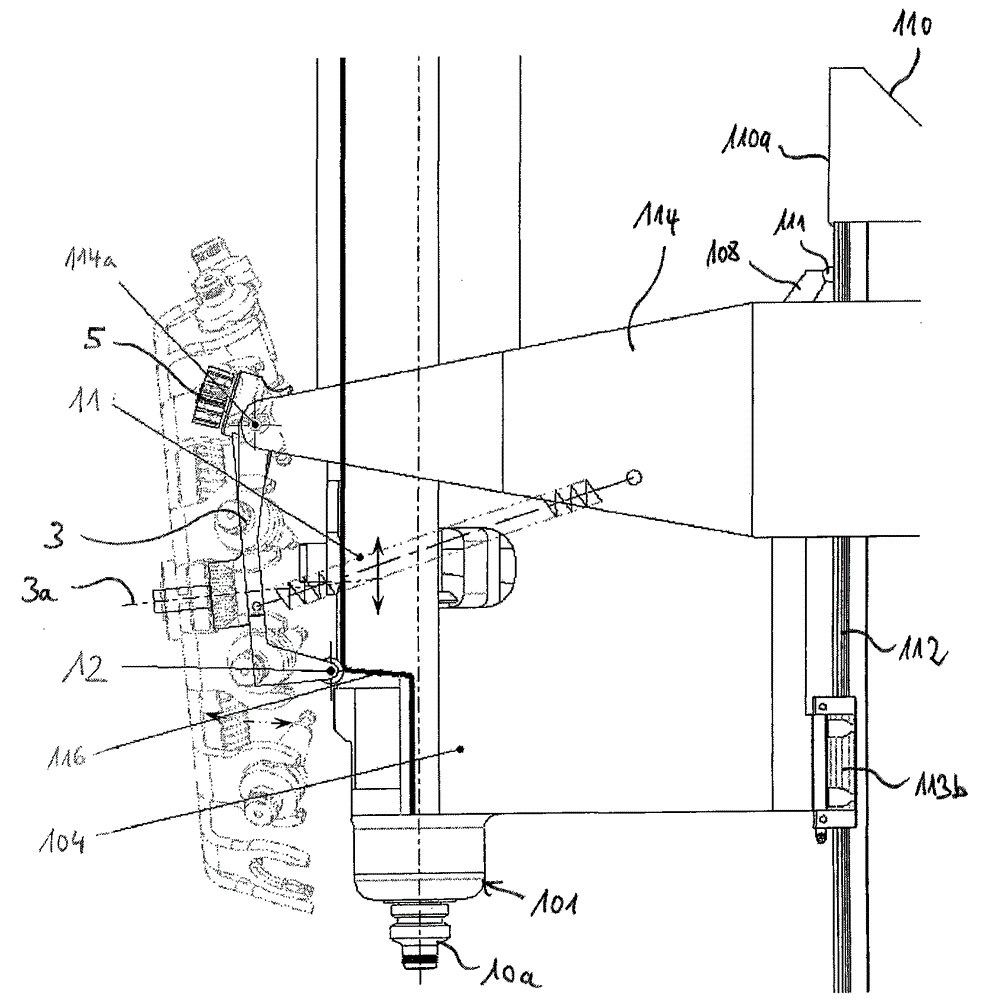

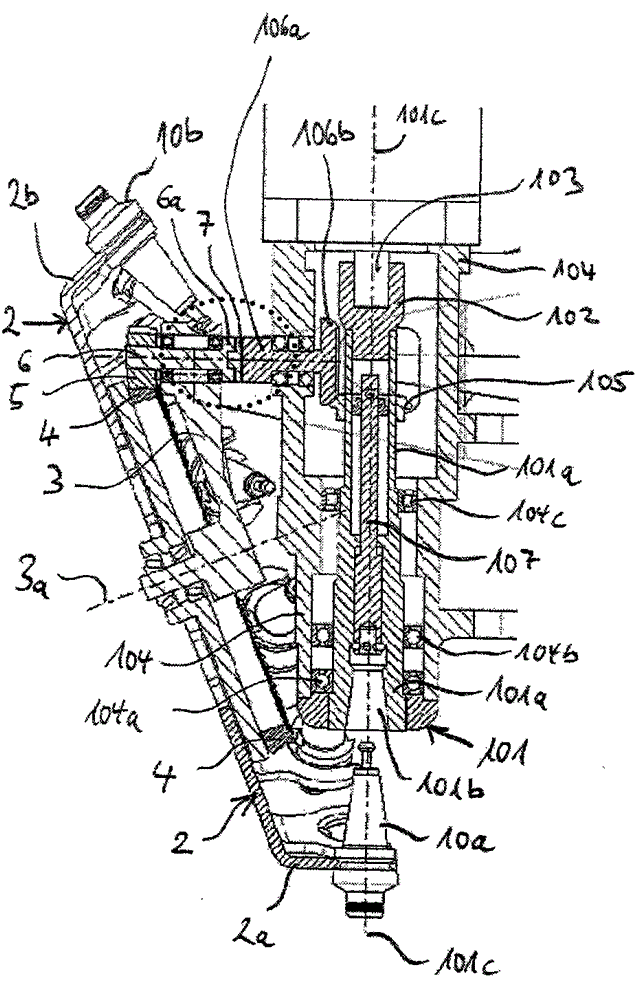

[0050] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. However, the invention is not limited to the described embodiments. The scope of the present invention is determined by the claims. In the figures, the same or similar features are indicated with the same reference numerals. about figure 2 , 5 and 6, it should be noted that these points mark the ends of these reference lines and should not be understood as technical details of the objects shown. figure 2 , 5 The corresponding reference lines in and 6 with corresponding end points are drawn to be at least partially linear. These at least partially linear reference lines do not represent any technical details of the objects shown. Figure 3A The dots in the dots also do not represent any technical details of the objects shown, but merely illustrate a section of the figure, which is in Figure 3B with 3C Shown in magnified and stereoscopic form.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com