A mobile lens pole electrostatic precipitator with rotating dust cleaning brush

A technology of electrostatic precipitator and moving lens, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problem of the increase of emission concentration and dust emission concentration, affecting the dust removal efficiency of electrostatic precipitator, the increase of hourly average value and daily average value. High-level problems, to achieve the effect of reducing dust emission concentration, reducing secondary dust volume, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

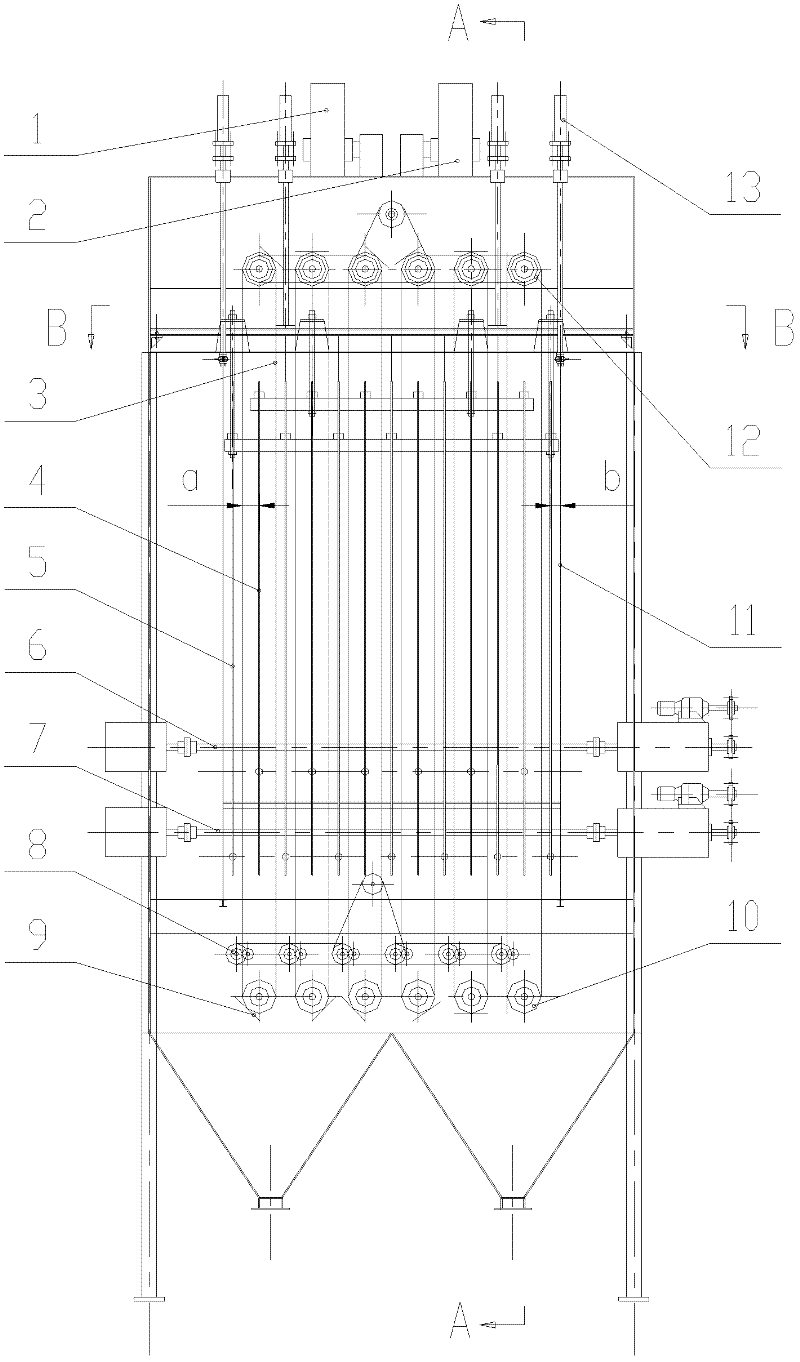

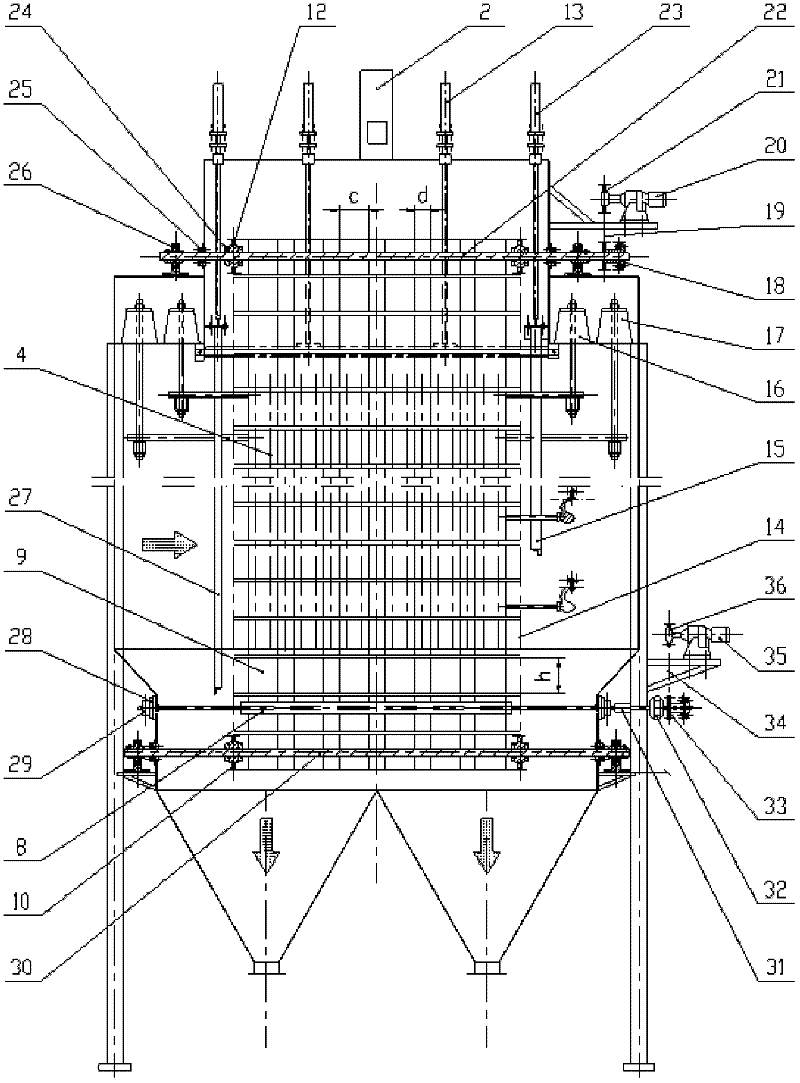

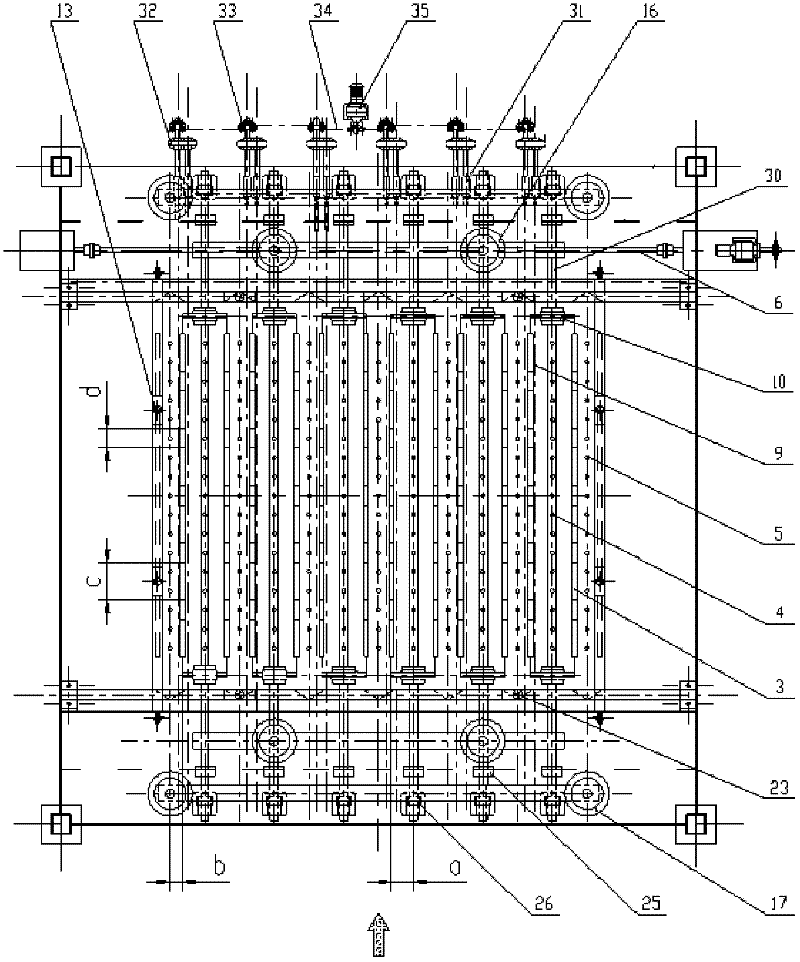

[0032] After the flue gas flows into the moving lens electrostatic precipitator with rotating dust cleaning brush from the inlet flue, the flue gas after dust removal by the first electric field, the second electric field, the third electric field and the lens electric field is discharged from the outlet flue. figure 1 This is a schematic diagram of the structure of the lens-type electric field and related components in this embodiment, figure 2 for figure 1 A-A section view, image 3 for figure 1 B-B cross-sectional view. Such as figure 1 , 2 As shown in Fig. 3, the present invention includes a positive corona pole 5, a negative corona pole 4, a lens pole 3 located in a lens-type electric field, and a rotating dust cleaning brush 8 installed under the dust collection area of the lens-type electric field. Among them, the positive corona pole 5 uses twisted wire, connected to the positive high voltage power supply 1, and the dust is cleaned by rapping; the negative corona pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com