An intelligent motor control cabinet

A technology of intelligent motor and control cabinet, applied in the field of control cabinet, can solve the problems of insufficient reliability, scalability and flexibility, affecting the operation of downstream networking equipment, inconvenient installation and maintenance, etc., to save power distribution room space and cabinets Body size, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

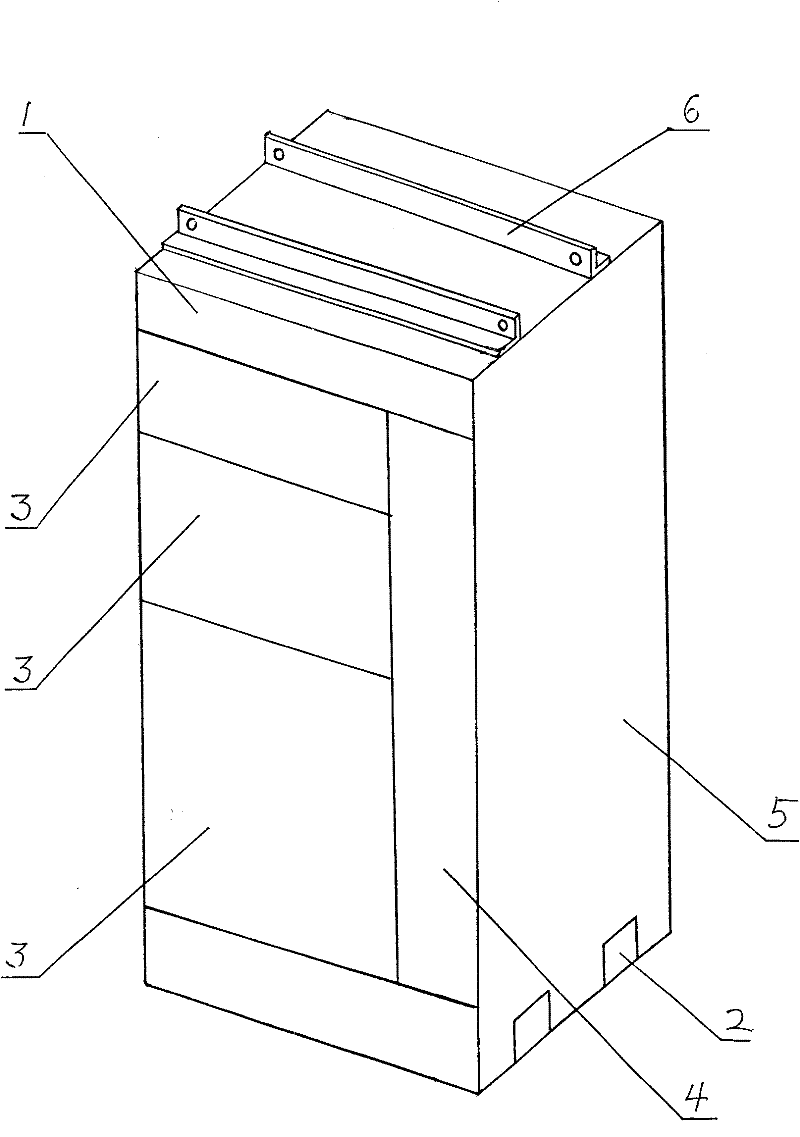

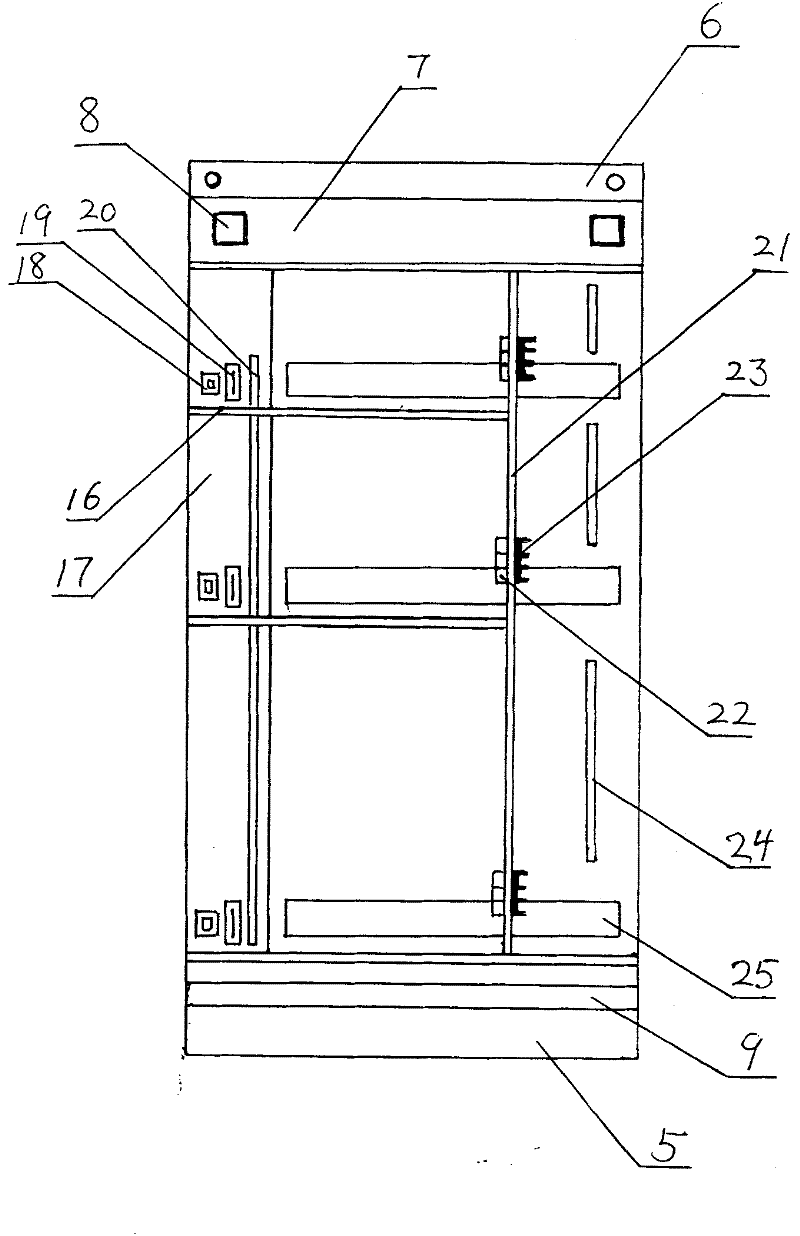

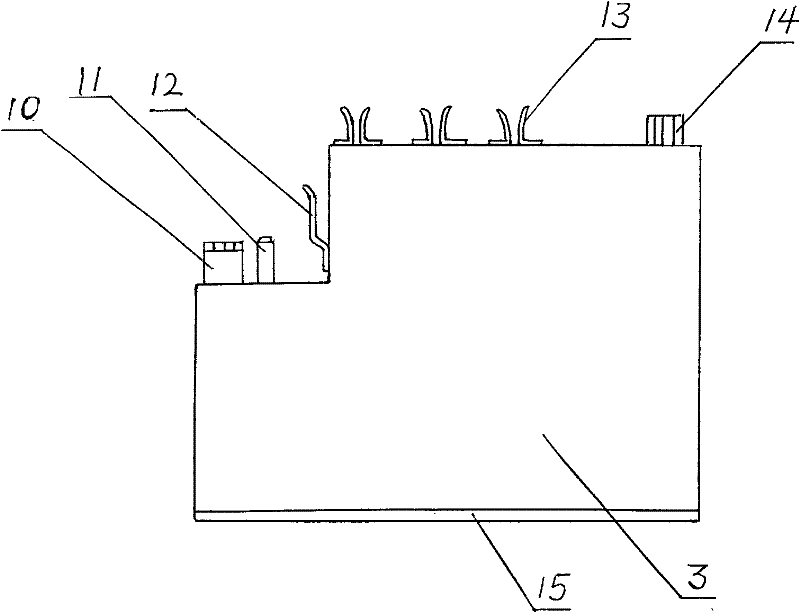

[0012] Such as figure 1 , figure 2 , image 3 As shown, the intelligent motor control cabinet of the present invention is composed of a top horizontal room 1, a grounding aisle 2, a drawer unit 3, a wire and cable room 4, and a cabinet body 5. A network control fixing plate is installed in the top horizontal room 1 7. A network connection module 8 is installed on the network control fixing plate 7; a grounding bar 9 is installed in the grounding aisle 2; each motor control loop is installed in each of the drawer units 3; The rear of the drawer unit 3 is equipped with a network plug-in 10, a control plug-in 11, a grounding plug-in 12, a wire plug-in 13, and a load plug-in 14; a door 15 is installed in the front of the drawer unit 3; A unit layer board 16 is installed between the drawer units 3; the rear of the cabinet body 5 is equipped with a control line installation board 17, and a corresponding network plug-in 18 is installed on the control line installation board 17 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com