Calorific value corrected membrane gas meter

A membrane gas meter and calorific value technology, which is applied in the direction of contraction/expansion volume, etc., can solve the problems of popularization obstacles, uncertainty of calorific value measurement of membrane gas meters, high manufacturing cost of electronic gas meters, etc., and achieve low manufacturing cost , suitable for industrial production and easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

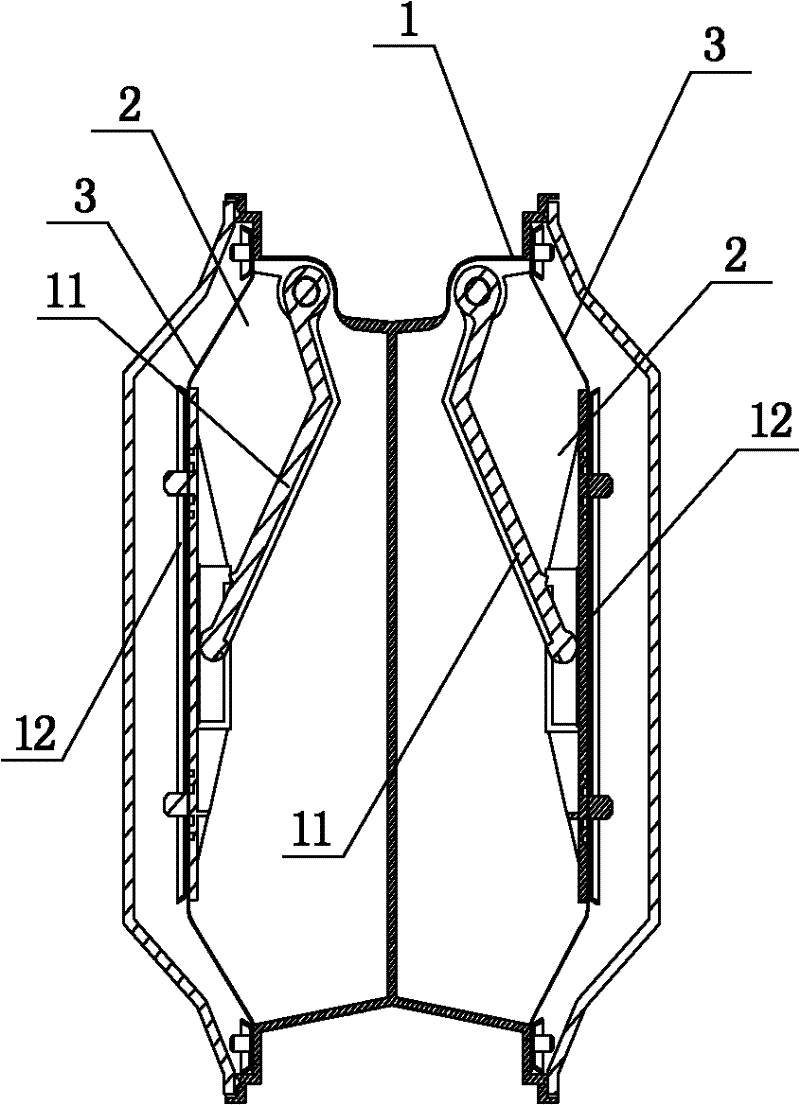

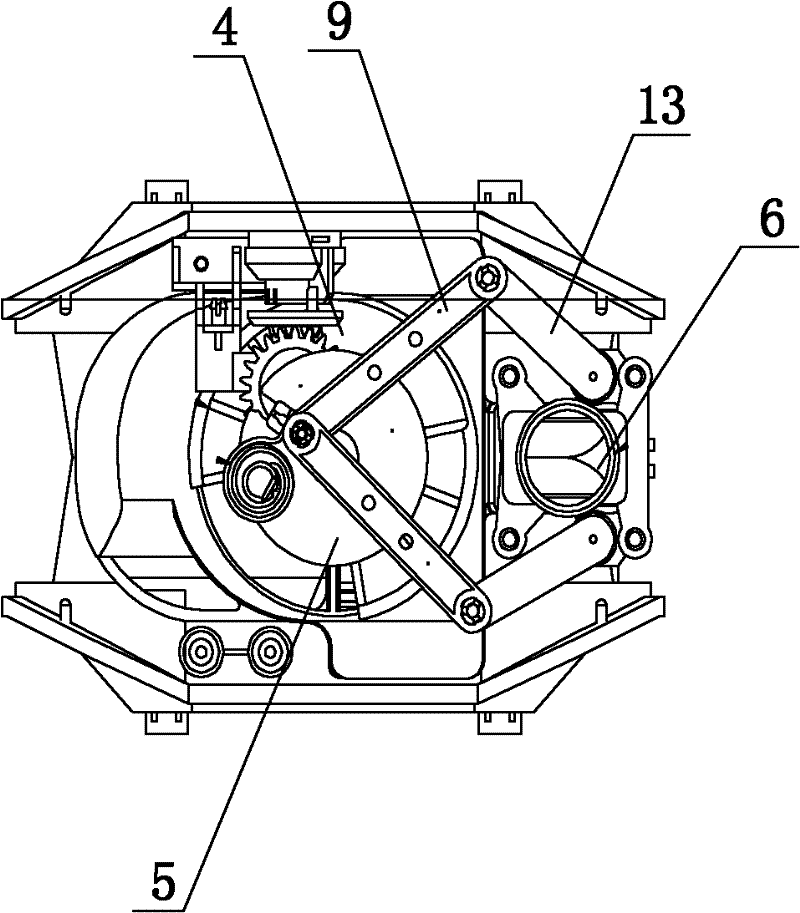

[0033] The present invention also provides a calorific value corrected diaphragm gas meter. The gas meter includes the diaphragm gas meter core and casing described in Embodiment 1, specifically as follows: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, and the facility on the gas meter has an air inlet and an air outlet, the air inlet communicates with the air inlet of the gas distribution valve bonnet 4, and the air outlet communicates with the outlet cylinder 6 on the movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com