A kind of polymer type optical lens antifogging agent and preparation method thereof

An optical lens and polymer-based technology, applied in the field of material chemistry, can solve the problems of easy loss of surfactant and poor anti-fog durability, etc., and achieve the effects of long anti-fog time, rapid response, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

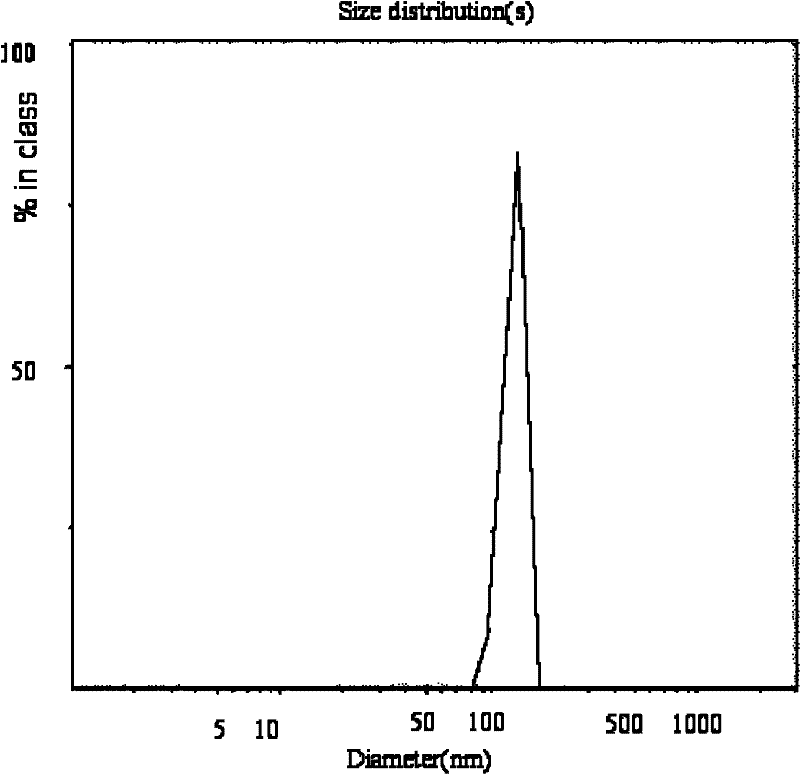

Image

Examples

Embodiment 1

[0032] Recipe screening:

[0033] The transmittance (transmittancy, T) and antifogging time (antifogging time, AT) are important indicators for evaluating the quality of polymer antifogging films, and there are many factors that affect them. Select the four main factors that have a greater impact on the evaluation indicators, and each Take 3 levels for each factor, see Table 1, press L 9 (3 4 ) to arrange orthogonal experiments. In order to reduce the experimental error, each group of experiments was randomly carried out 3 times, and the average value was taken for analysis, and the quality identification of the best prescription was carried out.

[0034] Table 1 Level-Factor Index

[0035]

[0036] Note: A-sec-octylphenol polyoxyethylene ether (TX-10) concentration (%); B-sodium dodecylbenzene sulfonate (SDBS): isopropanol (wt.%); C-isopropanol : ethanol (wt.%); D-percentage of water (wt.%).

[0037] Table 2 Analysis results of orthogonal test

[0038]

[0039] Tab...

Embodiment 2

[0049] Preparation of Antifog Film for Polymer Optical Lens

[0050] Reagents and materials:

[0051] 2-octylphenol polyoxyethylene ether (TX-10) Sinopharm Group

[0052] Sodium dodecylbenzenesulfonate (SDBS) Sinopharm Group

[0053] Isopropanol Sinopharm Group

[0054] Ethanol Sinopharm Group

[0055] Step 1: Preparation of polymer antifogging agent

[0056] This anti-fogging agent is made by mixing base solution and additives in a certain proportion. First use 1.5 parts by mass of 2-octylphenol polyoxyethylene ether colorless transparent liquid, abbreviated as TX-10, 10 parts by mass of isopropanol, 30 parts by mass of absolute ethanol and 48 parts by mass of double distilled water, mix Compose 100mL of base solution; then weigh 2-6 parts of sodium dodecylbenzenesulfonate white solid powder, abbreviated as SDBS, add about 100 parts by mass of double distilled water, and prepare an aqueous solution with a concentration of 4.0% as an additive, and base The liquid is mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com