Electric water disinfection device

A disinfection device and water quality technology, applied in mechanical oscillation water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of low energy saving, many by-products, carcinogenic dangerous substances, etc., to prevent scaling , The effect of increasing the amount of treated water and strong sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

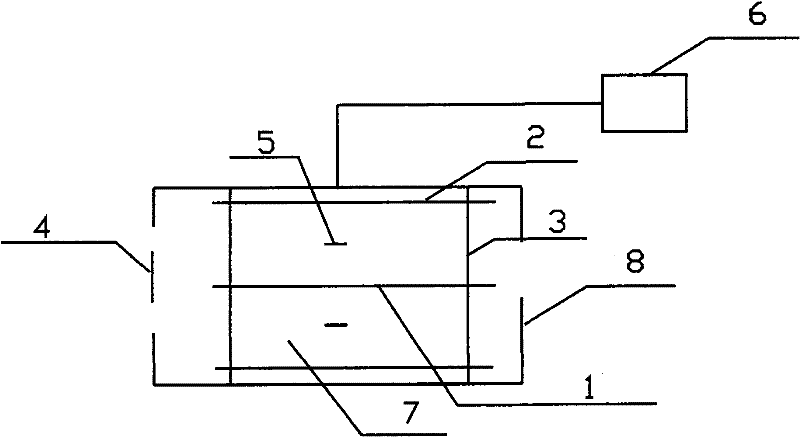

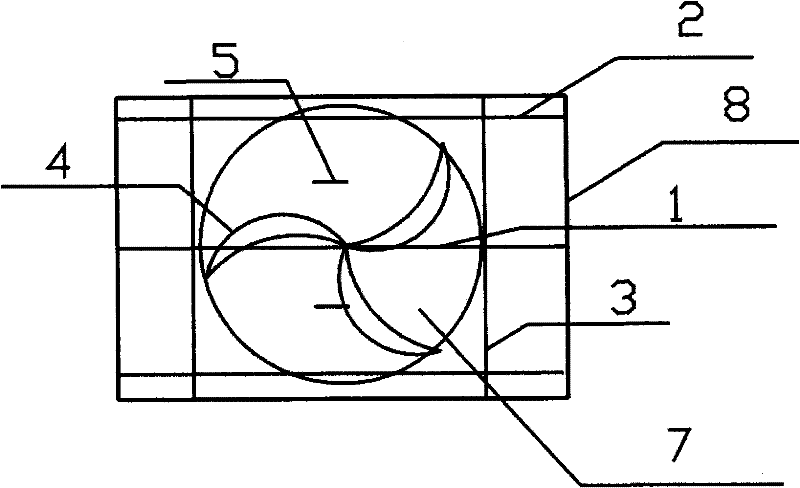

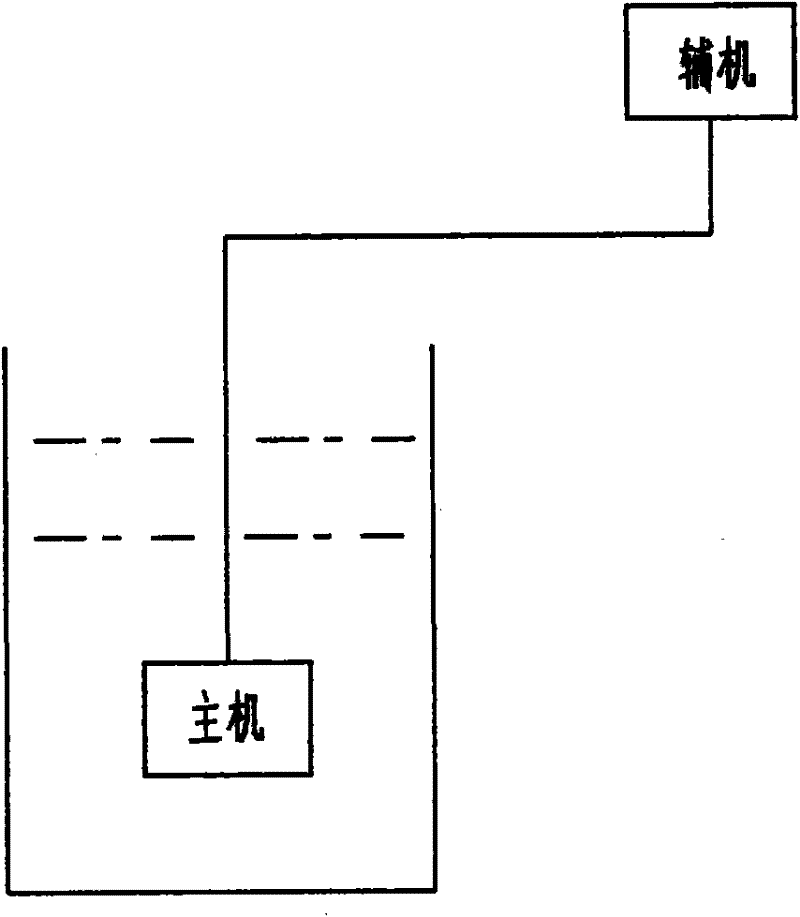

[0033] exist figure 1 Among them, the electro-excited water quality disinfection device of the present invention includes a host machine 7 and an auxiliary machine 6. The casing 8 of the main engine is a rectangular parallelepiped, the left side is the water inlet, and the right side is the water outlet. The anode plate 1 and the cathode plate 2 are made of titanium metal. The anode plate 1 and the cathode plate 2 are sheet-shaped and arranged at relative intervals. And through the electrode insulation support 3 fixed in the host 7, arranged in turn from the bottom of the host of the device to the top, the ultrasonic energy converter 5 is fixed between the anode plate and the cathode plate, the micro water pump 4 is fixedly installed at the water inlet of the device, and the auxiliary machine 6 It consists of solar panels, energy converters, and energy controllers. The distance between the anode plate and the cathode plate is 3.5-5.5cm. The ultrasonic energy converter is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com