A combined system of advanced oxidation-separation crystallization for high-salt industrial wastewater

An industrial wastewater, advanced oxidation technology, applied in energy wastewater treatment, alkali metal compounds, water/sewage multi-stage treatment, etc. problems, to achieve the effect of overcoming incomplete COD removal, significant economic and social benefits, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

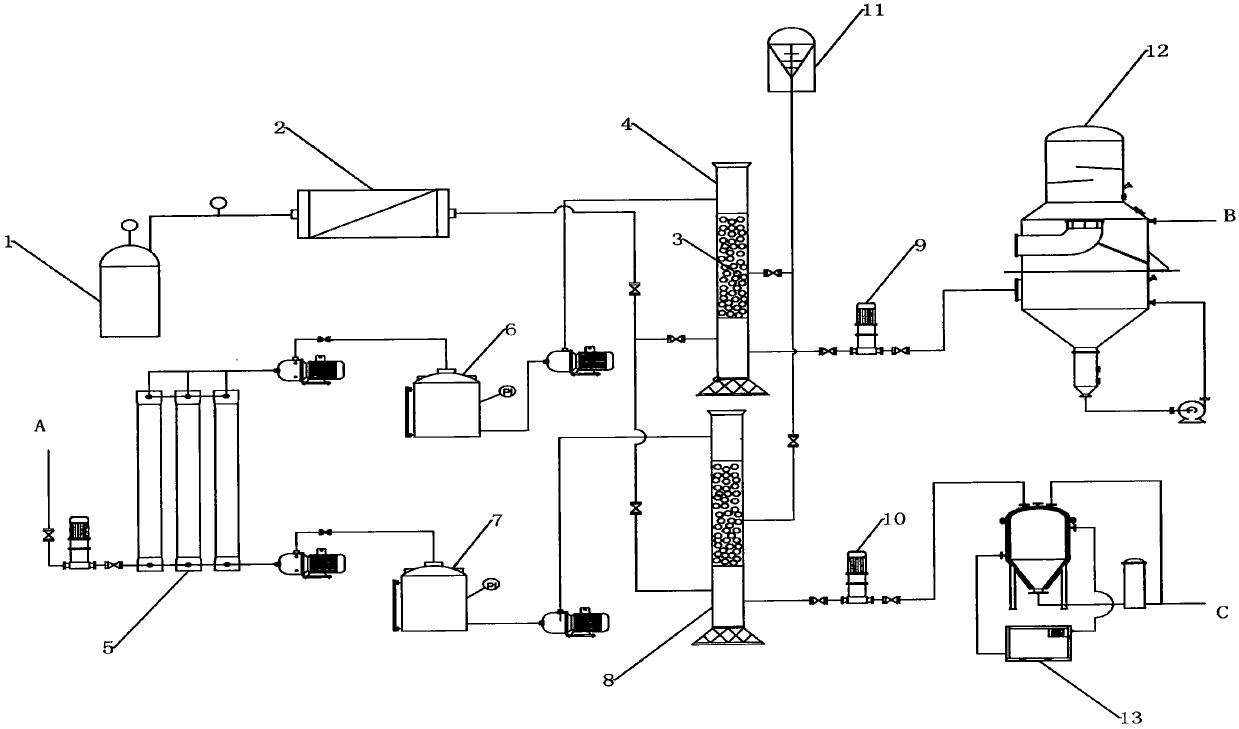

[0041] The present invention adopts a cooling crystallization system for the resourceful treatment of the concentrated sodium sulfate solution, which is in the form of a cooling graded crystallizer, and is optimized and combined with a complete continuous cooling crystallization device system. The system adopts a cooling crystallization type graded crystallizer, which can effectively guarantee the space and residence time required for crystallization; the system can complete the two-step operation of crystal growth and crystal particle classification, which greatly simplifies the production process and provides easy operation of the device. efficiency;

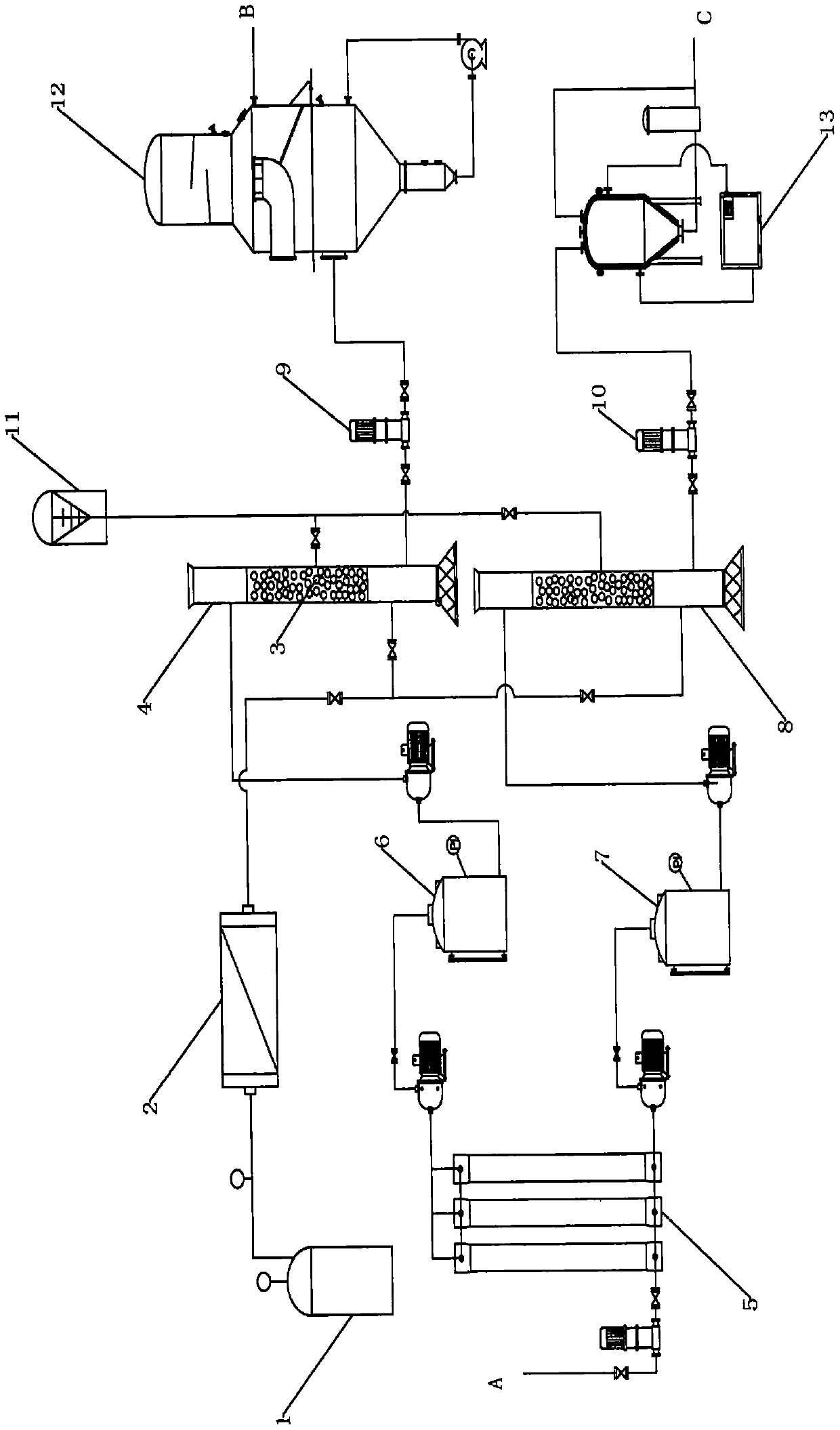

[0042] Such as figure 1 As shown, in order to verify the treatment effect of ozone oxidation of the present invention on COD in wastewater, combined figure 1 , taking the high-salt wastewater treatment project of a coal chemical enterprise as an example to illustrate. Industrial high-salt water fluctuates greatly, and its co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com