A comprehensive recovery process of desulfurization waste liquid auxiliary salt in coking plant

A technology for desulfurization waste liquid and auxiliary salt, which is applied in the direction of ammonium sulfate, thiosulfate/dithionite/polythionate, thiocyanate, etc., which can solve the problem of reducing the desulfurization effect and cannot fundamentally Solve problems, production equipment corrosion and other problems, achieve the effect of low energy consumption, avoid secondary pollution, and clear process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

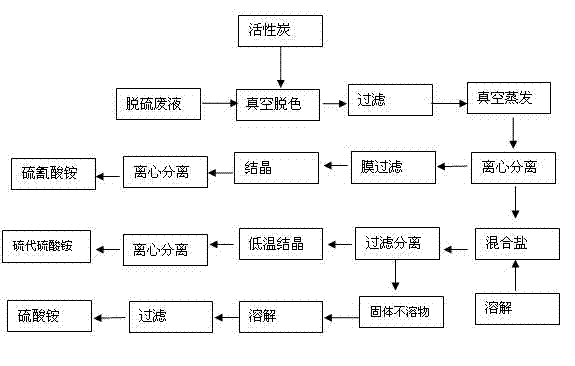

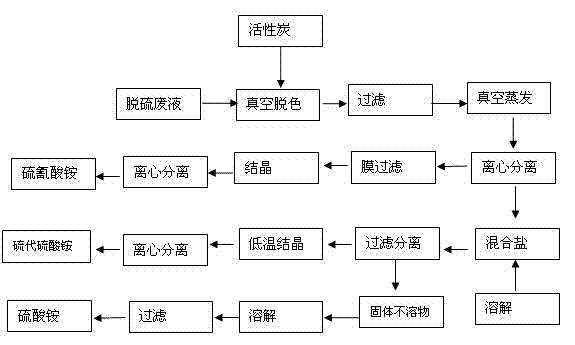

Image

Examples

Embodiment 1

[0021] Take 1000g of desulfurization wastewater from coking enterprises (21.35% ammonium thiocyanate, 18.75% ammonium thiosulfate, 1.25% ammonium sulfate), decolorize at 5000Pa and 75°C for 5 hours at a vacuum degree, and put the decolorized liquid into the evaporating kettle at 5000Pa , 390 grams of water evaporated at 80°C. Cool down to 60°C, and use a centrifuge to separate out 148 grams of ammonium thiosulfate / ammonium sulfate compound salt; the separated liquid is filtered at 55°C, and the filtered liquid enters the crystallization kettle for crystallization, and the solution for washing the finished product of ammonium thiocyanate is added for 45 gram, the crystallization temperature is 25°C, the cooling rate is 3°C / h, kept at this temperature for 2h, centrifuged and washed to obtain 162g of finished ammonium thiocyanate, with a purity of 97.4% and a sulfur content of less than 0.05%. Add 148g of the separated ammonium thiosulfate / ammonium sulfate compound salt to 180g o...

Embodiment 2

[0023] Take 1000g of desulfurization wastewater from coking enterprises (ammonium thiocyanate 18.32%, ammonium thiosulfate 17.75%, ammonium sulfate 0.64%), first decolorize it at 5000Pa in vacuum at 75℃ for 5 hours, and put the decolorized liquid into the evaporating kettle at 5000Pa , 470 grams of water evaporated at 80°C. Cool down to 55°C, and use a centrifuge to separate 126 grams of ammonium thiosulfate / ammonium sulfate compound salt; the separated liquid is filtered at 50°C, and the filtered liquid enters the crystallization kettle for crystallization, and 35 g of the solution for washing the finished product of ammonium thiocyanate is added. grams, the crystallization temperature is 30°C, the cooling rate is 2°C / h, kept at this temperature for 1h, centrifuged and washed to obtain 146 grams of finished ammonium thiocyanate, with a purity of 96.8% and a sulfur content of less than 0.05%. Add 126g of the separated ammonium thiosulfate / ammonium sulfate compound salt to 134g...

Embodiment 3

[0025] Others are the same as in Example 2, except that the evaporated liquid after removing the ammonium thiosulfate does not adopt membrane filtration before entering the crystallization tank, and the cooling rate of ammonium thiocyanate crystallization is 6° C. / h. As a result, 132 grams of finished product ammonium thiocyanate was obtained, with a purity of 95.4%, and a sulfur content of 0.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com