Numerical control servo indexing mechanism for crankshaft connecting rod neck

A technology of crankshaft connecting rod and indexing mechanism, which is applied to metal processing mechanical parts, machine tools designed for grinding the rotating surface of workpieces, precision positioning equipment, etc., can solve the problem of low indexing accuracy, achieve wide applicability, improve Radial angle accuracy, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

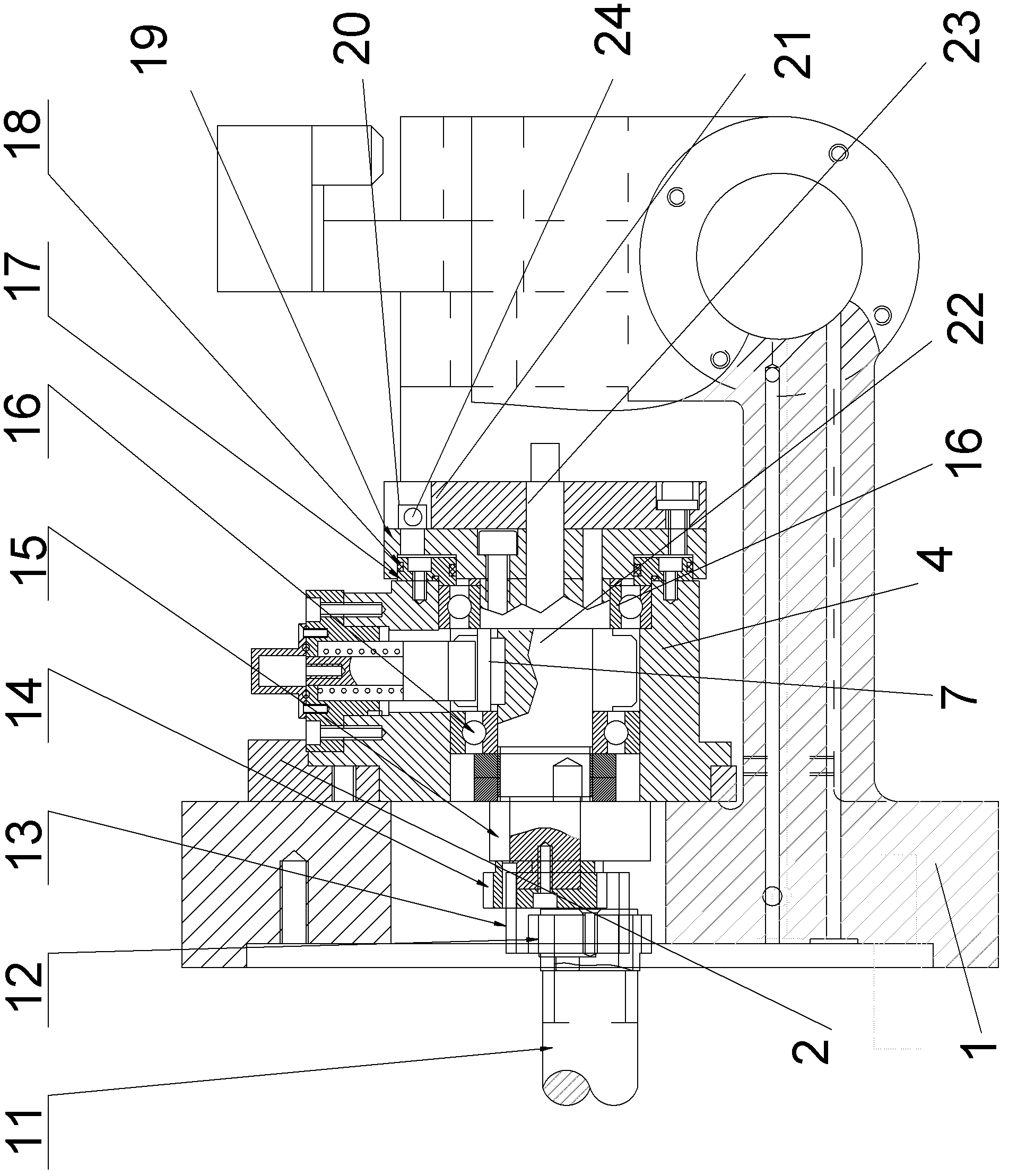

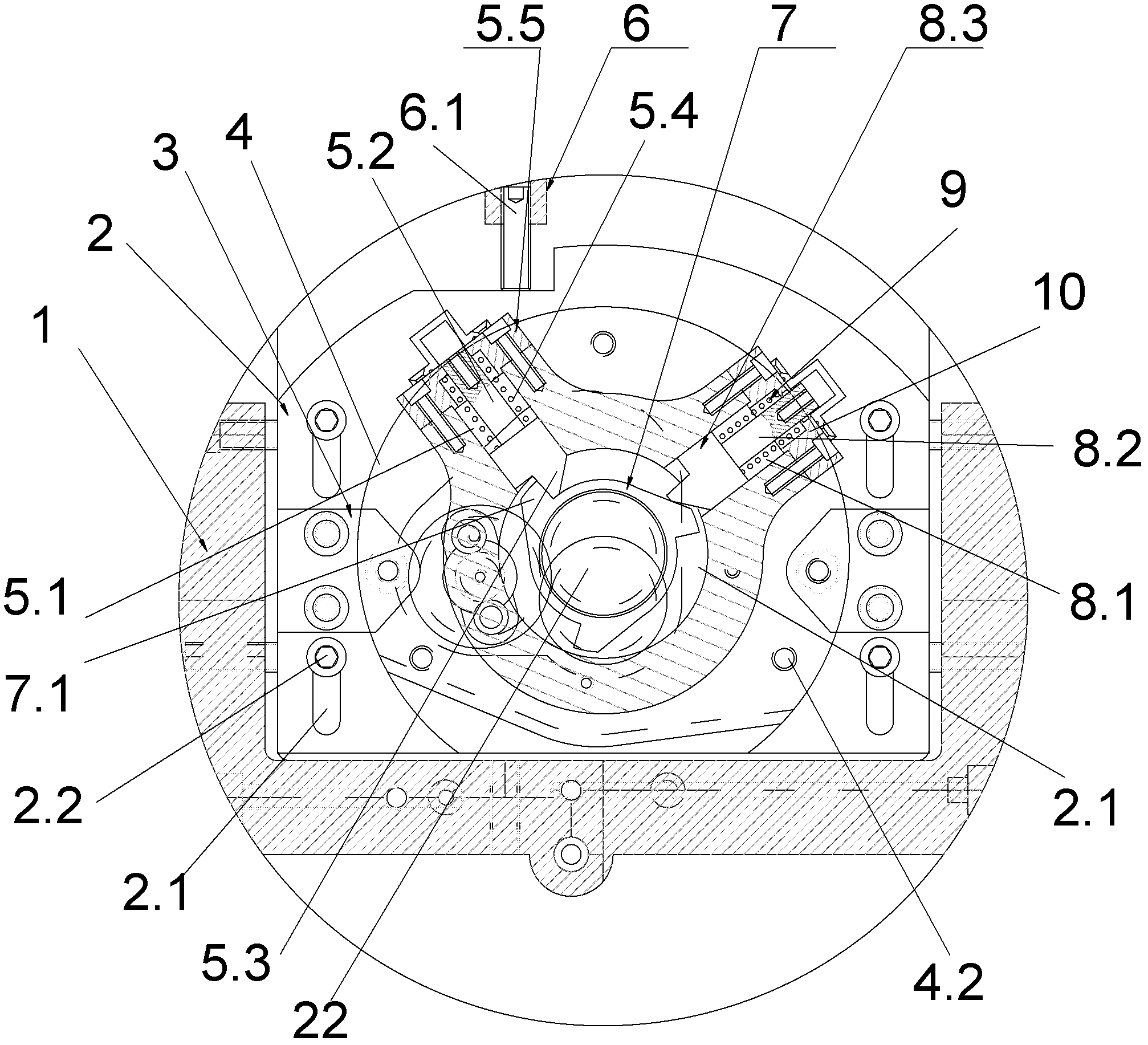

[0020] The mechanism of the present invention is used for servo indexing of CNC crankshaft grinder to illustrate, as figure 1 As shown, the support frame in the technical solution is the clamp body 1 of the CNC crankshaft grinder, and the indexing head seat 2 is connected with the clamp body 1, as figure 2 As shown, the indexing head seat 2 is provided with a long adjustment hole 2.1, and the bolt 2.2 passes through the long adjustment hole 2.1 to connect the indexing head seat 2 with the clamp body 1. Clamp body 1 is provided with adjusting nut 6, and adjusting nut 6 is connected with screw rod 6.1, and screw rod 6.1 end faces contact with the side of indexing head seat 2, can make like this when installing now with the up and down center position of fine-tuning indexing head seat 2.

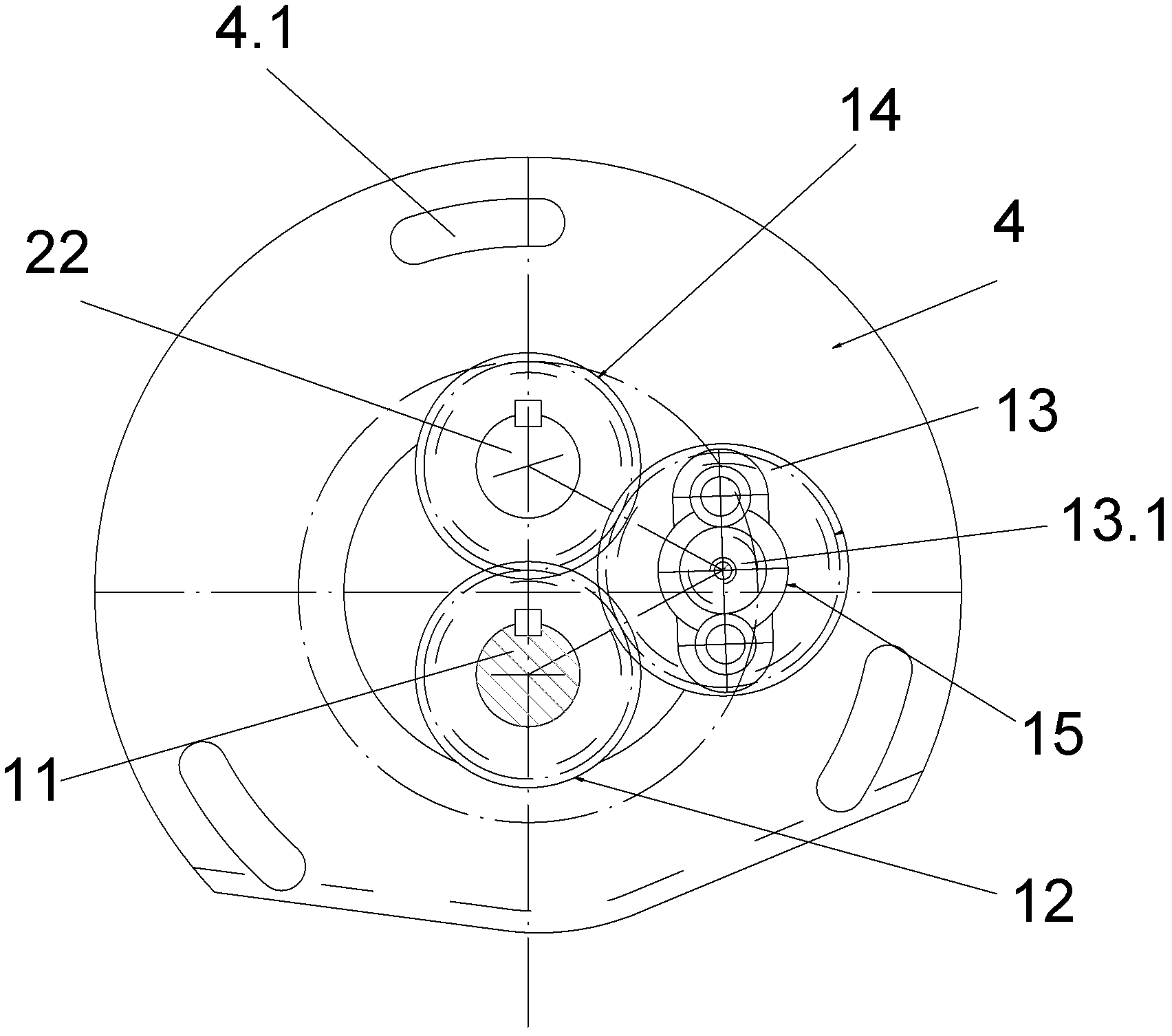

[0021] Another example figure 2 As shown, the indexing head seat 2 is connected with the indexing box 4, such as image 3 As shown, the indexing box 4 is provided with an arc connection gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com