Ternary-cerium-based oxygen storage material and preparation method thereof

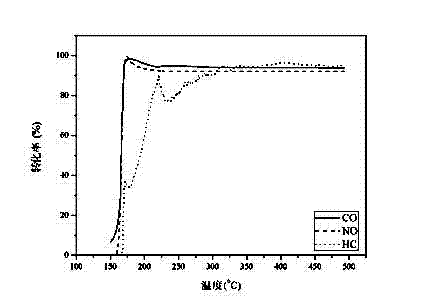

A technology of oxygen storage materials and rare earth materials, which is applied in the field of ternary cerium-based oxygen storage materials and its preparation, can solve the problems of insufficient total oxygen storage capacity, dynamic oxygen storage performance, and insufficient high-temperature sintering resistance, and achieve stable and efficient storage Oxygen capacity, reduction of precious metal usage, and effects of weakening fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Weigh the rare earth compound Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 )4·5H 2 O, La(NO 3 ) 3 ·6H 2 O, dissolved in 1400mL of deionized water to prepare a solution with a metal ion concentration of about 0.5mol / L, adding hydrogen peroxide solution with a volume of 1% of the solution, and adding barium nitrate with a mass of 5% solid solution. Prepare a 3mol / L ammonia solution and a 3mol / L ammonium carbonate solution and mix them in a volume ratio of 1:1 as a precipitant.

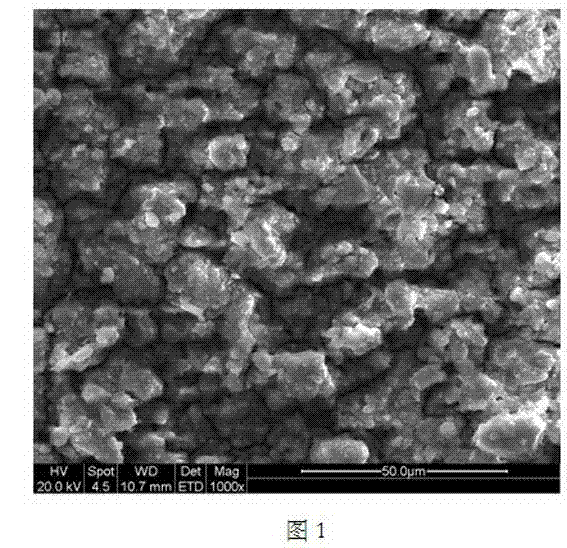

[0057] Under 45°C constant temperature water bath and 200Kw ultrasonic conditions, the mixed solution and the precipitating agent are stirred in parallel in an appropriate proportion, and the pH of the solution is controlled at 8 during the concurrent flow. Stirring was continued for 1 h after co-flow was completed. Then add polyethylene glycol with a solid solution mass of 8% to adjust the pH to 10. After aging at 100° C. for 4 hours, take it out, and let it stand at room temperature for 12 hours. The p...

Embodiment 2

[0062] Weigh the rare earth compound Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 )4·5H 2 O, La(NO 3 ) 3 ·6H 2 O, dissolved in 1400mL of deionized water to prepare a solution with a metal ion concentration of about 0.5mol / L, add 0.5% hydrogen peroxide solution by volume, and 5% copper nitrate by solid solution mass. Prepare a 3mol / L ammonia solution and a 3mol / L ammonium carbonate solution and mix them in a volume ratio of 1:1 as a precipitant.

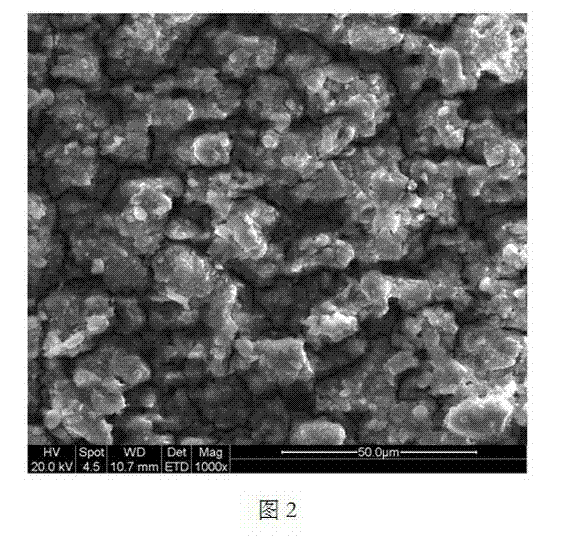

[0063] Under the conditions of 80°C constant temperature water bath and 200Kw ultrasonic conditions, the mixed solution and the precipitating agent are stirred in parallel in an appropriate proportion, and the pH of the solution is controlled at 8 during the concurrent flow. Stirring was continued for 1 h after co-flow was completed. Then add polyethylene glycol with 5% solid solution mass to adjust the pH to 10. Stand at room temperature for 12h. The precipitate was suction filtered, washed with deionized water, pH = 7, and dried at 120° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com