Sea cucumber microbial fermented feed and preparation method thereof

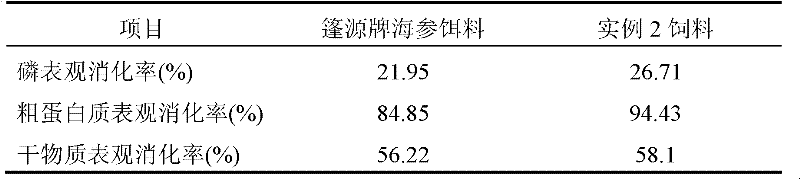

A technology of microbial fermentation and microecological preparations, applied in the field of environment-friendly sea cucumber microbial fermented feed and its preparation, can solve problems such as feed nutrition imbalance, water pollution, feed waste, etc., to increase palatability and digestibility, and improve digestibility , the effect of avoiding the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Pretreatment of feed raw materials, drying until the water content is not higher than 15%, and coarsely crushing to 100-200 mesh;

[0030]Step 2: Weigh 3kg of large leafy vegetable powder, 1kg of degummed kelp powder, 0.5kg of squid offal powder, 1kg of fish meal, 1.5kg of sargassum powder, 1.5kg of sargassum powder, 0.5kg of zeolite powder, 0.5kg of shell powder, and multivitamins and minerals 0.3kg, compound enzyme preparation 0.2kg;

[0031] After weighing, the raw materials are placed in the mixer, fully stirred and mixed to obtain the basic feed;

[0032] Step 3: Weigh 0.01kg urea and 0.01kg glucose, dissolve them in 0.1kg sterile water, and mix the obtained solution evenly into the basic feed;

[0033] Step 4: Add 0.4kg of solid bacillus preparation to the raw material and mix evenly;

[0034] Step 5: Under the condition of 45°C, solid-state fermentation for 48 hours, and the thickness of the material is 150cm;

[0035] Step 6: Drying, inspection, packa...

Embodiment 2

[0037] Step 1: Pretreatment of feed raw materials, drying until the water content is not higher than 15%, and coarsely crushing to 100-200 mesh;

[0038] Step 2: Weigh 4kg of large leafy vegetable powder, 1kg of degummed kelp powder, 0.5kg of squid offal powder, 1kg of fish meal, 1.5kg of sargassum powder, 1.5kg of sargassum powder, 0.5kg of zeolite powder, 1kg of shell powder, multivitamin and Mineral 0.2kg, compound enzyme preparation 0.2kg

[0039] After weighing, the raw materials are placed in the mixer, fully stirred and mixed to obtain the basic feed;

[0040] Step 3: Weigh 0.01kg urea and 0.01kg glucose, dissolve them in 0.11kg sterile water, and mix the obtained solution into the basic feed evenly;

[0041] Step 4: Add 0.2kg of solid bacillus preparation to the raw material and mix evenly;

[0042] Step 5: Under the condition of 40°C, solid-state fermentation for 24 hours, and the thickness of the material is 150cm;

[0043] Step 6: Drying, inspection, packaging, a...

Embodiment 3

[0045] Step 1: Pretreatment of feed raw materials, drying until the water content is not higher than 15%, and coarsely crushing to 100-200 mesh;

[0046] Step 2: Weigh 4kg of leafy vegetable powder, 1.2kg of degummed kelp powder, 0.5kg of squid viscera powder, 1kg of fish meal, 1.5kg of sargassum powder, 1.5kg of sargassum powder, 0.3kg of zeolite powder, 1kg of shell powder, and multivitamins and minerals 0.1kg, compound enzyme preparation 0.2kg;

[0047] After weighing, the raw materials are placed in the mixer, fully stirred and mixed to obtain the basic feed;

[0048] Step 3: Weigh 0.01kg urea and 0.01kg glucose, dissolve them in 0.11kg sterile water, and mix the obtained solution into the basic feed evenly;

[0049] Step 4: Add 0.3kg of solid bacillus preparation to the raw material and mix evenly;

[0050] Step 5: Under the condition of 50°C, solid-state fermentation for 24 hours, and the thickness of the material is 100cm;

[0051] Step 6: Drying, inspection, packagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com