Aluminium electrolytic capacitor used for LED lamp and working electrolyte employed by aluminium electrolytic capacitor

A technology of aluminum electrolytic capacitors and LED lights, which is applied in the field of aluminum electrolytic capacitors and electrolytic capacitors, can solve problems such as unstable physical and chemical properties of the working electrolyte at high temperature, failure to meet the requirements of aluminum electrolytic capacitors, and poor ripple current resistance, and achieve improved Service life and ripple current resistance, good economic and social benefits, and the effect of reducing volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

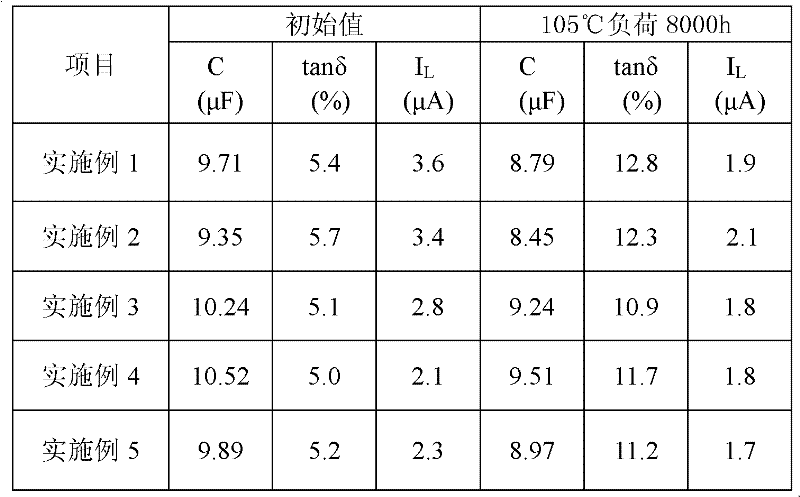

Examples

Embodiment 1

[0039] Prepare the electrolyte according to the following mass percentages:

[0040] Main solvent: 85.7% glycerol.

[0041] Auxiliary solvent: 5% ethylene glycol.

[0042] Solute: 2% 30-branched carbon potassium salt, 1% potassium sebacate, 1% sebacic acid. The total content is 4%.

[0043] Preservatives: 0.5% ammonium metatungstate, 0.5% ammonium metasilicate. The total content is 1%.

[0044] Additives for improving flash voltage and high temperature stability: 3% polyvinyl formal, 1% ammonium dichromate.

[0045] The total content is 4%.

[0046] Hydrogen remover: 0.2% glucono delta lactone.

[0047] Waterproof mixture: 0.02% hypophosphite, 0.08% ammonium hypophosphite. The content is 0.1%.

[0048] Heat the main solvent and auxiliary solvent to 70-90°C, add the solute, heat to 110-135°C and turn off the heat, add additives, hydrogen scavenger and water-repellent mixture to dissolve them completely, and then cool naturally.

Embodiment 2

[0050] Prepare the electrolyte according to the following mass percentages:

[0051] Main solvent: 73.4% glycerol.

[0052] Auxiliary solvent: 5% ethylene glycol, 5% diethylene glycol. The total content is 10%.

[0053] Solute: 2% 30-branched carbon potassium salt, 3% potassium azelate, 1% azelaic acid, 2% sebacic acid. The total content is 8%.

[0054] Preservatives: 1% pentaerythritol, 1% silicotungstic acid. The total content is 2%.

[0055] Additives for improving flash voltage and high temperature stability: 4% p-aminobenzenesulfonic acid, 1% ammonium dichromate, 1% silicone oil. The total content is 6%.

[0056] Hydrogen remover: 0.4% 2,4,6-trinitrophenol.

[0057] Waterproofing agent: 0.1% strontium nitrate, 0.1% polyphosphoric acid. The content is 0.2%.

[0058] Heat the main solvent and auxiliary solvent to 70-90°C, add the solute, heat to 110-135°C and turn off the heat, add additives, hydrogen scavenger and water-repellent mixture to dissolve them completel...

Embodiment 3

[0060] Prepare the electrolyte according to the following mass percentages:

[0061] Main solvent: 62.1% glycerol

[0062] Auxiliary solvent: 5% trimethyl phosphate, 5% triethylene glycol, 5% diethylene glycol. The total content is 15%.

[0063] Solute: 2% 30-branched carbon potassium salt, 4% potassium benzoate, 3% potassium azelate, 1% azelaic acid, 2% sebacic acid. The total content is 12%.

[0064] Preservatives: 1% pentaerythritol, 2% ammonium tungstate. The total content is 3%.

[0065] Additives for improving flash voltage and high temperature stability: 4% polyvinyl formal, 2% p-aminobenzenesulfonic acid, 1% silicone oil. The total content is 7%.

[0066] Hydrogen remover: 0.5% glucono δ lactone, 0.1% 2,4,6-trinitrophenol. The content is 0.6%. Waterproof mixture: 0.15% polyphosphoric acid, 0.15% sodium tripolyphosphate. The content is 0.3%.

[0067] Heat the main solvent and auxiliary solvent to 70-90°C, add the solute, heat to 110-135°C and turn off the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com