Material raising device for ramsbottom dryer

A lifting device and dryer technology, which is used in drying, drying solid materials, lighting and heating equipment, etc., can solve the problem of high material breakage rate, and achieve the effect of reducing the lifting height, simple structure and slowing collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

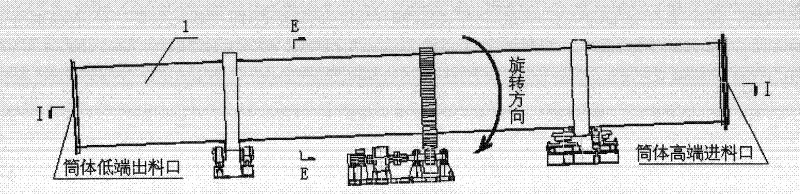

[0021] figure 1 It is the outline drawing of the semi-coke dryer with a lifting device installed in the cylinder 1 cavity of the present invention. It has a tilting and rotating cylinder 1. The material enters the lifting device through the high end of the cylinder 1 and is completed in the lifting device. After drying, the material is discharged from the lower end of the barrel 1.

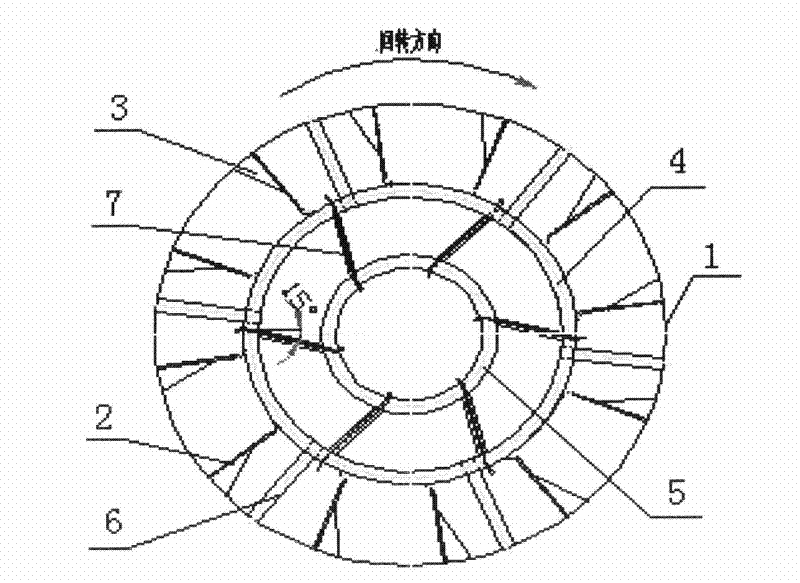

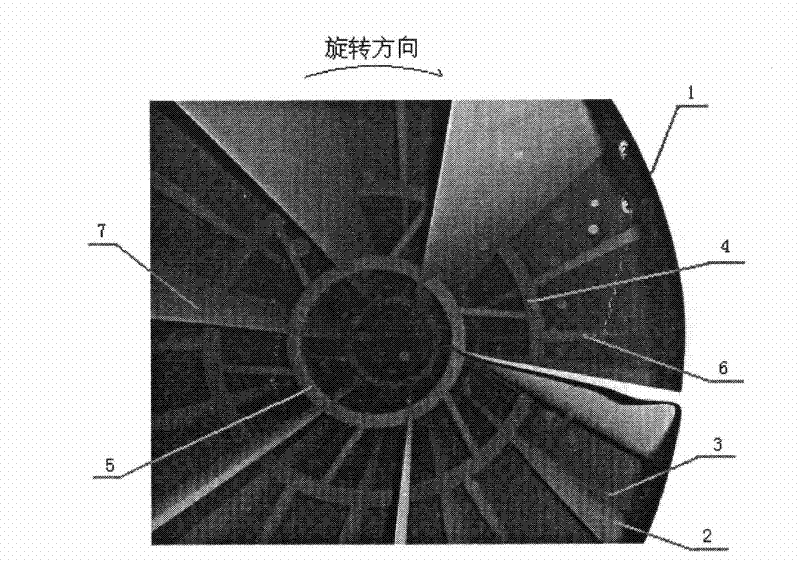

[0022] figure 2 yes figure 1 The E-E sectional view can reflect the main structure of this lifting device, wherein the lifting plate 2 is vertically connected to the inner wall surface of the cylinder 1 circumference, distributed evenly along the circumference, and the height is 1 / 4 of the radius of the cylinder 1. The plate 2 lifts up the material entering the lifting device with the rotation of the cylinder 1, and the lifting plate 2 is provided with a 130-degree bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com