Double-hopper loading device with automatic discharge turnover plates and seal gates and working method

An automatic feeding and double hopper technology, which is applied in the petroleum industry, coke cooling, coke oven, etc., can solve the problems of long operation time, large randomness of material distribution, and high work intensity, so as to achieve uniform material flow and improve uniformity , The effect of reducing equipment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

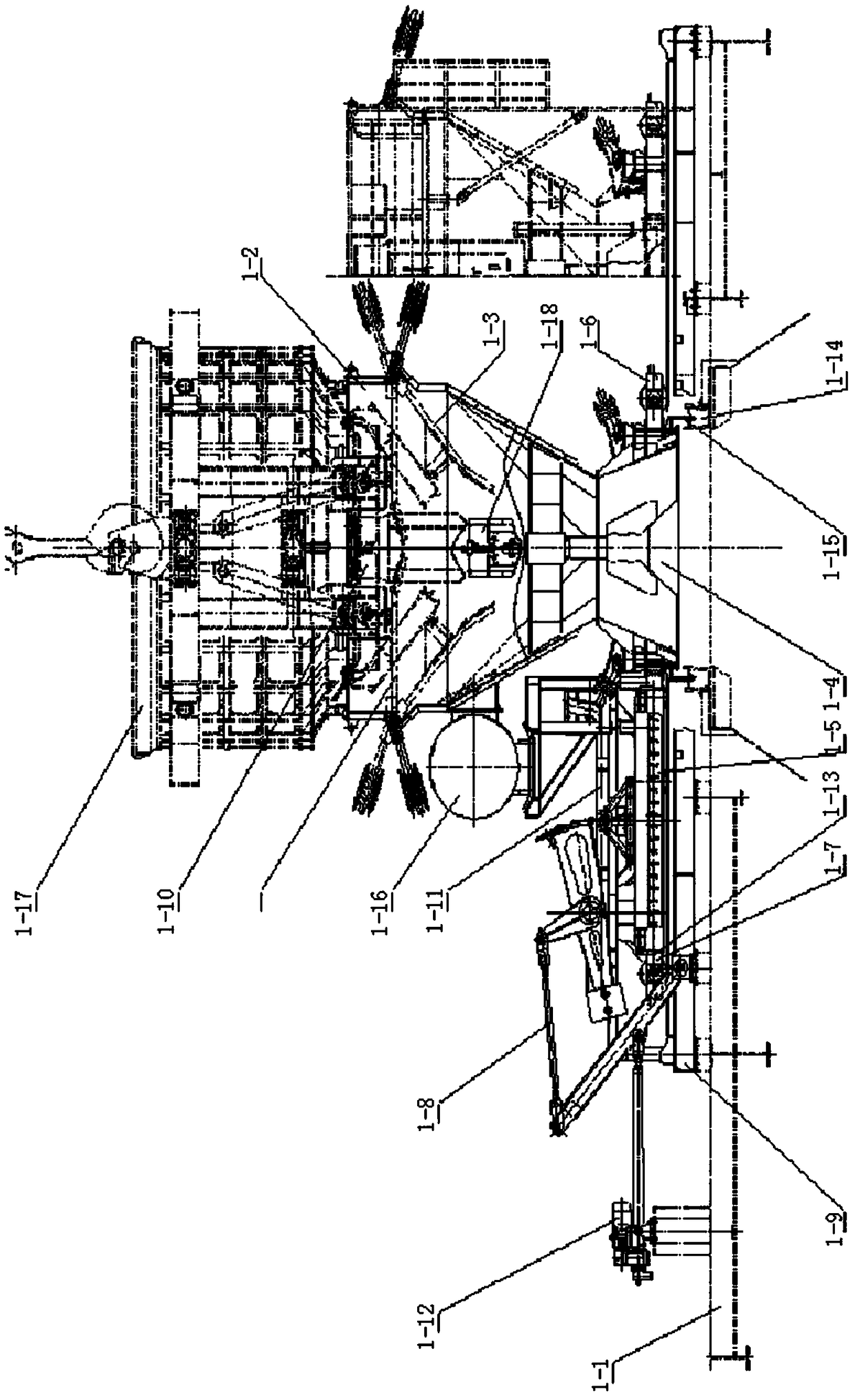

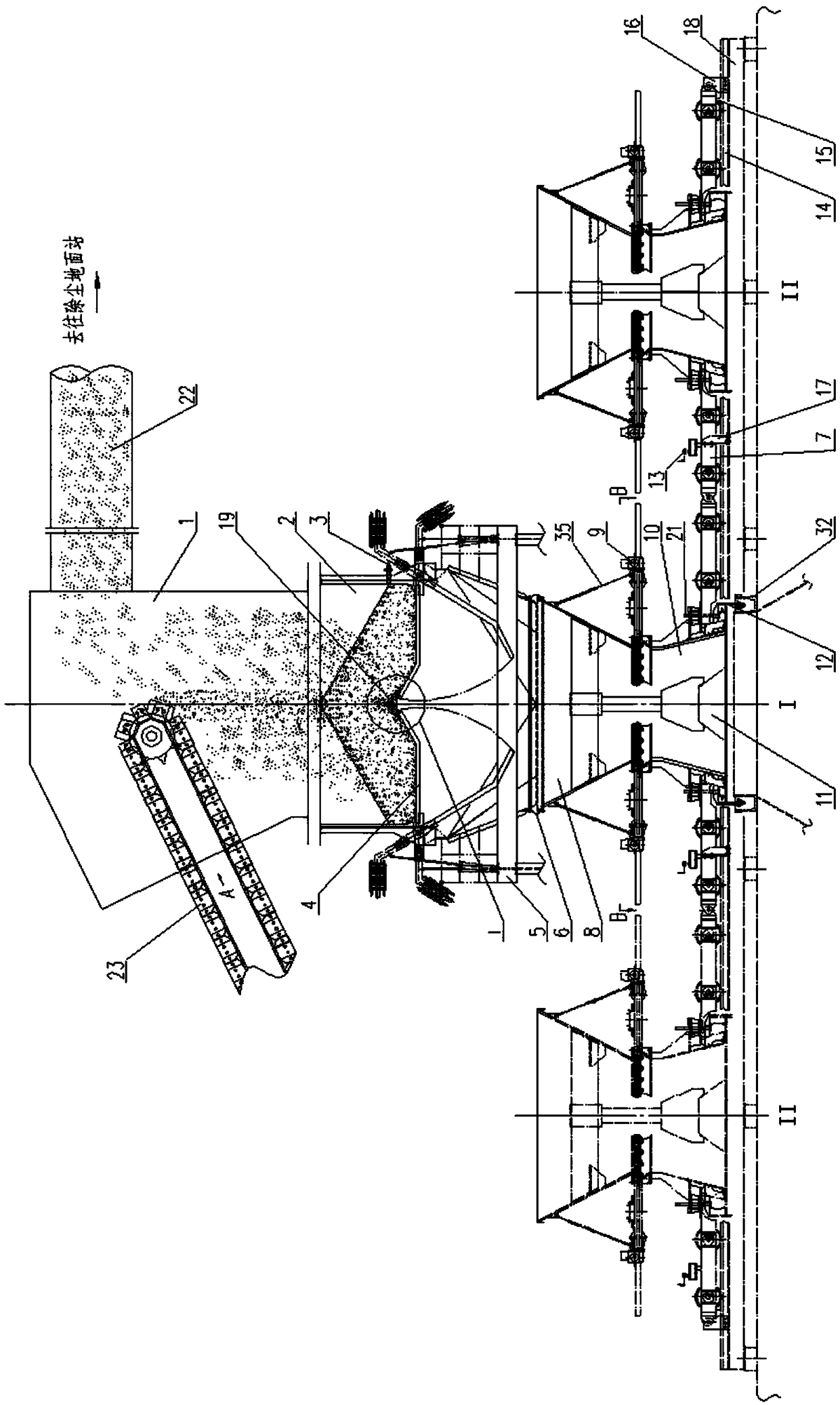

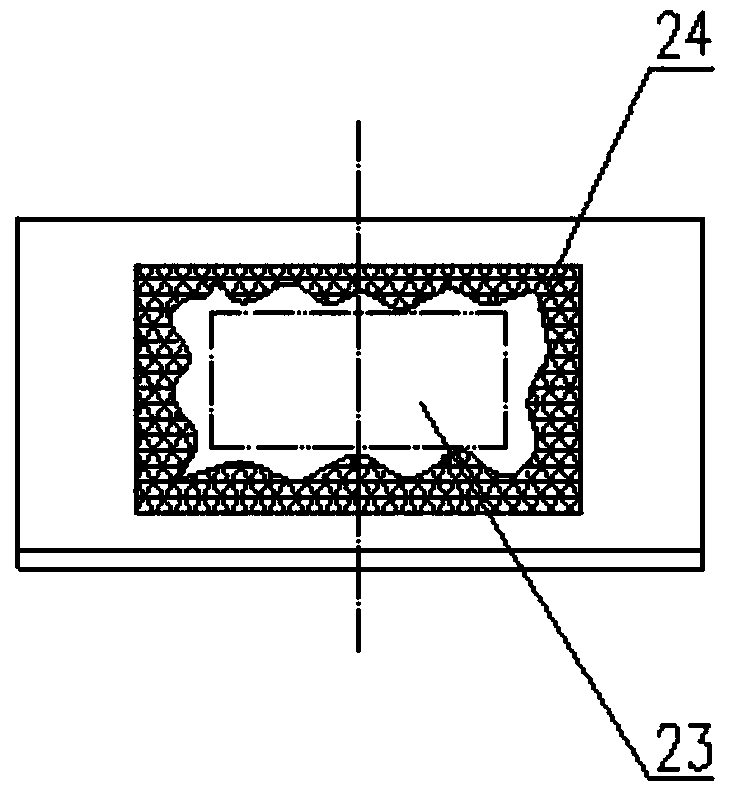

[0052] Such as figure 2 As shown, the double hopper loading device with automatic discharge flap and sealing gate of the present invention includes a loading unit, a dust collecting cover 1, a fixed hopper 2 and a dust collecting pipe 22; the fixed hopper 2 passes through a support frame 5Fixed on the loading platform, located directly above the mouth of the dry quenching furnace, the dust collecting hood 1 is located above the fixed hopper 2, and the two are connected and sealed by flanges; the upper side of the dust collecting hood 1 is equipped with a chain bucket for conveying The discharge port of the machine is connected to the dust collection pipe 22 on the other side, and is connected to the external dust removal ground station; there are two loading units, and each loading unit is moved by the trolley 7, the upper movable hopper 8, and the lower mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com