Heat-insulation ceiling lamp

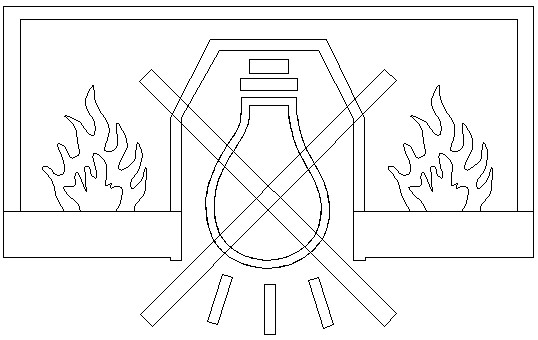

A technology for lamps and ceilings, applied in the field of lighting, can solve problems such as the difficulty of covering the surface of lamps with laminating materials, the inability to meet the low temperature of the surface of lamps, and the failure to reach a temperature lower than 90 degrees, so as to ensure safety, overall appearance, and good sound insulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

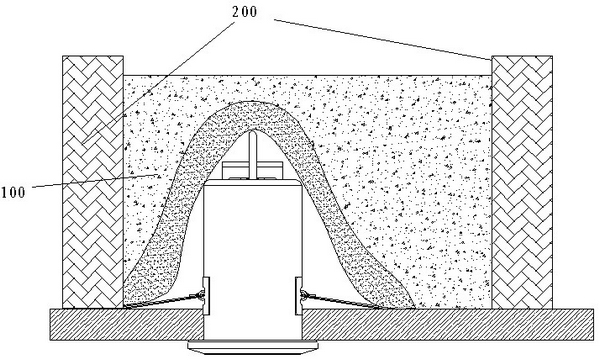

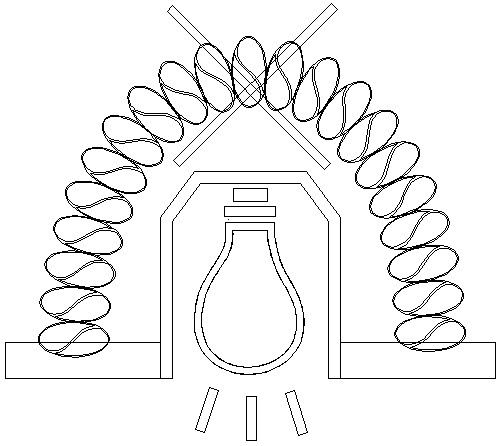

[0033] see Figure 4, Embodiment 1 of the heat-insulating ceiling lamp of the present invention, the shell of the heat-insulating ceiling lamp includes a tube cover 1 and a flange 2 located below the tube cover, the tube cover and the flange are both provided with a double-layer sealing structure 3, and the double-layer sealing structure 3 is provided. There is a cavity in the double-layer sealing structure, and the cavity is a vacuum structure, and the cavity in the double-layer sealing structure between the cylinder cover and the flange is connected.

[0034] In this embodiment, the outlet hole 4 on the top of the tube cover is designed to be sealed around, and the ceiling lamp is a sealed structure as a whole, which has the effects of heat preservation, heat insulation, and flame retardancy, and can block the loss of useful air in the room, and has the effect of sound insulation , the overall appearance is beautiful, and the production process is simple. And this tube cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com