Construction process of double-wall steel cofferdam for construction of pier bearing platform in main river water of Yellow River

A technology of double-walled steel cofferdam and construction technology, which is applied in basic structure engineering, construction, etc., can solve the problems of large input of manpower and material resources, long construction period, poor construction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

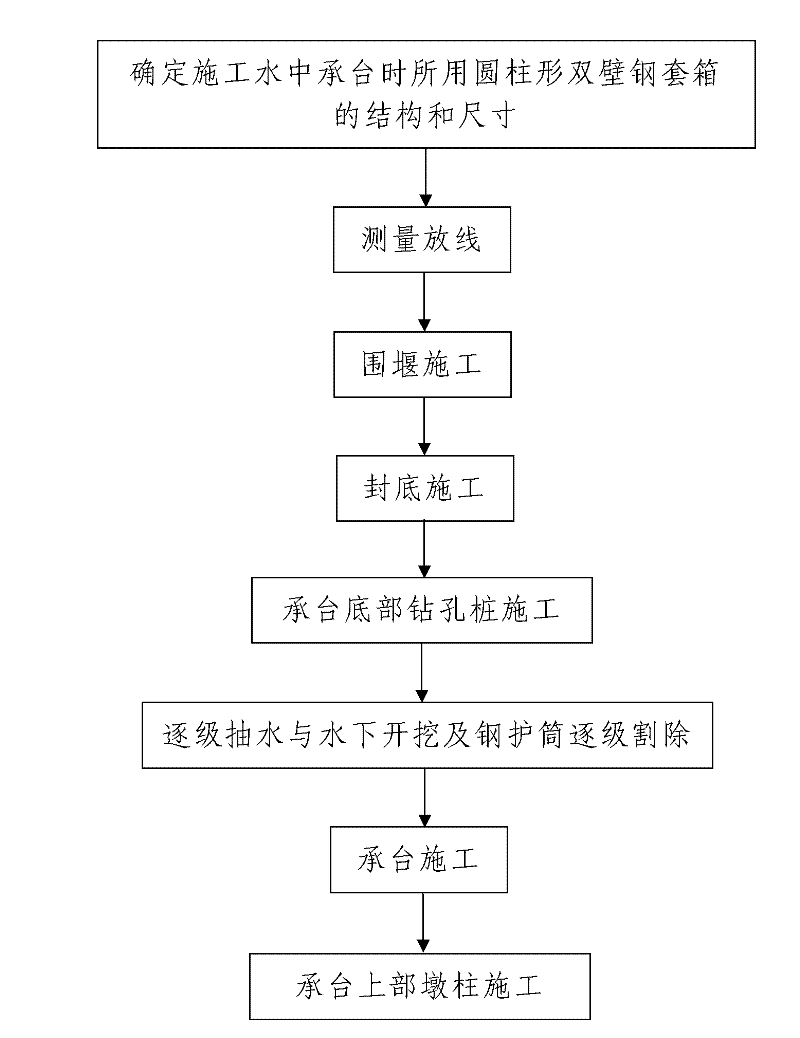

[0058] Such as figure 1 A kind of double-wall steel cofferdam construction technology for the construction of pier caps in the water of the main channel of the Yellow River shown includes the following steps:

[0059] Step 1. Determine the structure of the cofferdam used in the construction of the water cap according to the structure, size and bottom elevation of the water cap to be constructed, combined with the riverbed geological and hydrological conditions of the construction site and the work space to be reserved during the cofferdam construction and size.

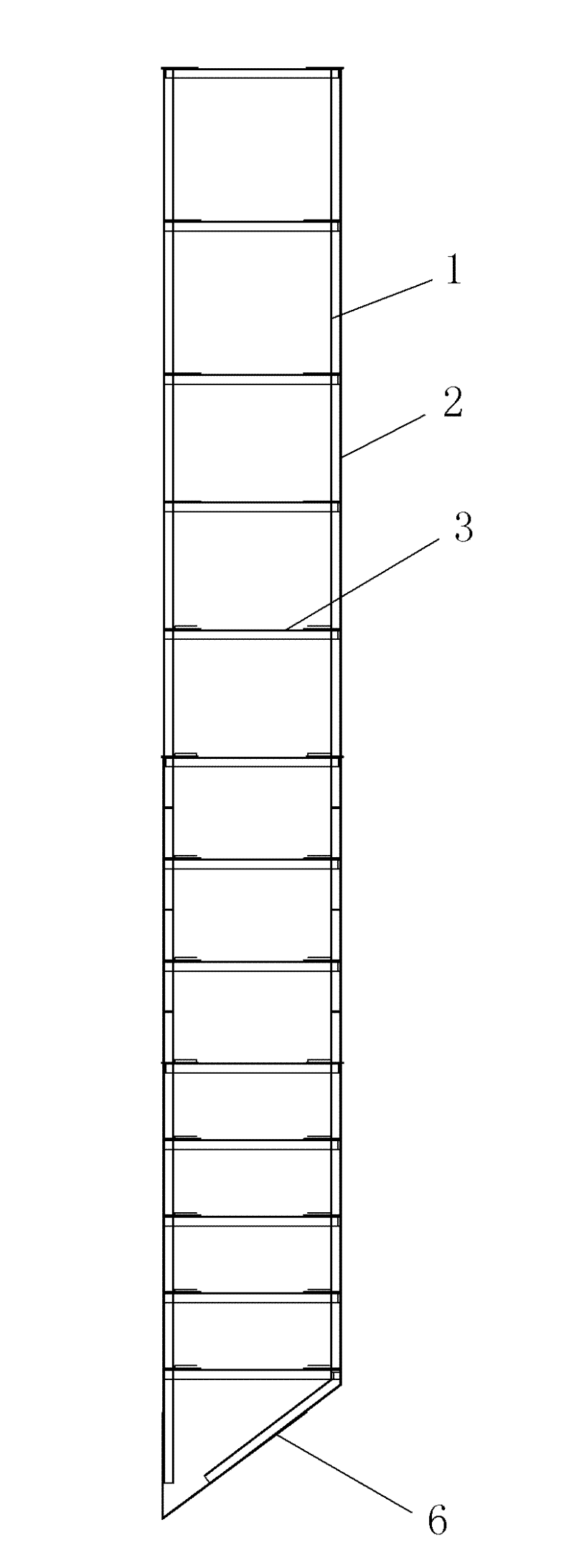

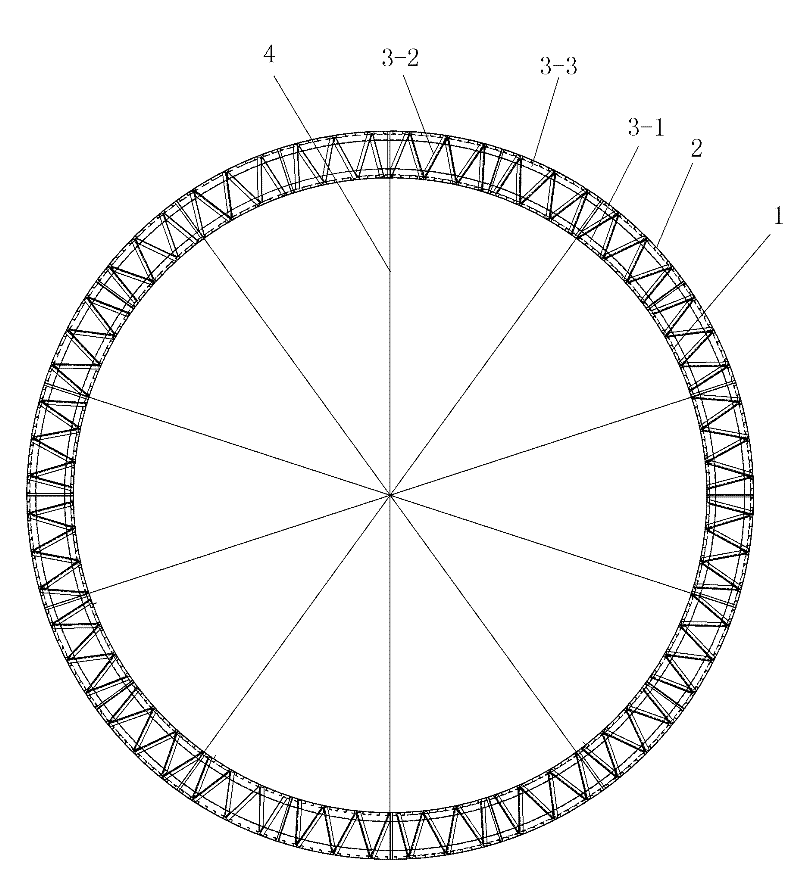

[0060] combine figure 2 , image 3 , the cofferdam is a cylindrical double-walled steel casing, and the cylindrical double-walled steel casing consists of an inner wall plate 1, an outer wall plate 2 coaxially set on the outer side of the inner wall plate 1, and multiple channels are installed from top to bottom. The horizontal truss 3 between the inner wall panel 1 and the outer wall panel 2 is composed of multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com