Preparation method of nickel titanium foam alloy with double pore structure

A foamed alloy and dual-porosity technology, applied in the field of nickel-titanium foamed alloy preparation, can solve the problems of low pore connectivity, uneven pore distribution, etc., and achieve smooth and rounded pore walls, uniform and controllable composition and structure, and good damping performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0055] Specific embodiment one: this embodiment is the preparation method of the nickel-titanium foam alloy of double pore structure, and it is realized through the following steps:

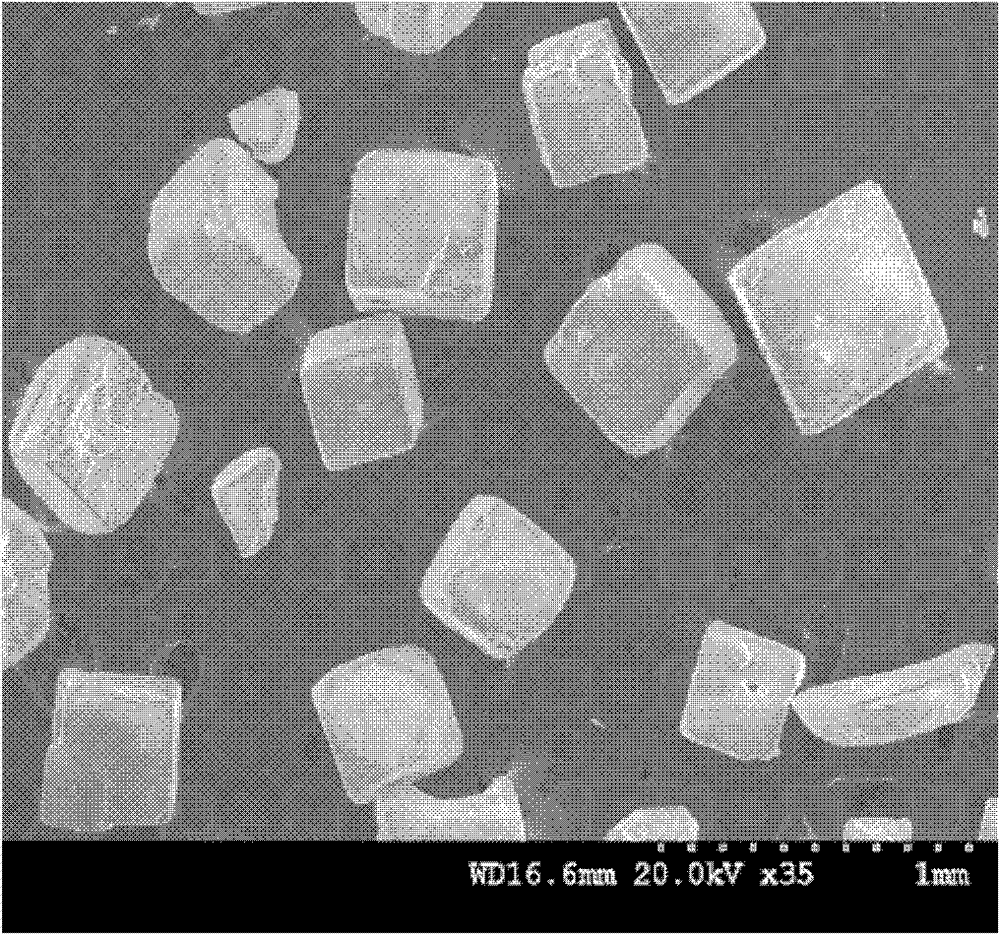

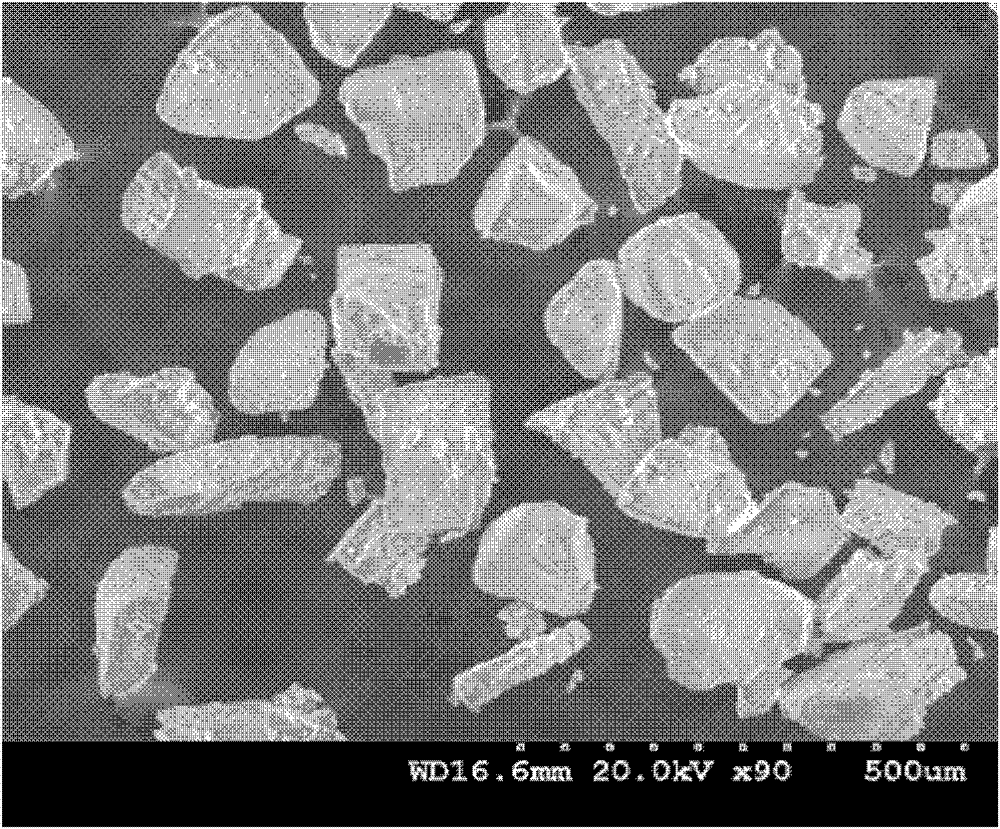

[0056] 1. Weigh the alloy raw material and sodium chloride filling, and control the quality of the sodium chloride filling to be 19% to 25% of the total mass of the alloy raw material and sodium chloride filling, and the alloy raw material is 55% to 56% by mass Nickel powder and 44% to 45% titanium powder, the sodium chloride filling is composed of 60% to 80% large particle sodium chloride and 20% to 40% small particle sodium chloride by mass percentage, large particle Sodium chloride and small particle sodium chloride are weighed separately, and then the alloy raw material and small particle sodium chloride are mixed to obtain mixed powder, and the height after the large particle sodium chloride and the mixed powder are controlled to spread evenly to the mold is 0.5 ~ 2mm, and the obtained One p...

specific Embodiment approach 2

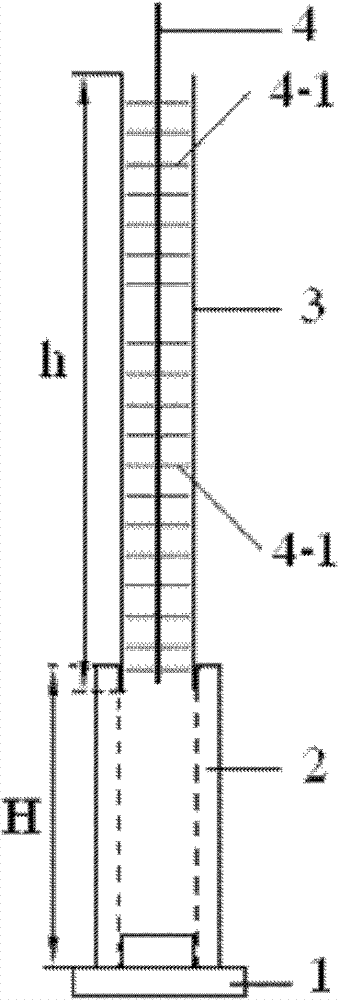

[0065] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 3, 20 to 200 parts of mixed powder obtained in step 2 and large-grained sodium chloride are sequentially laminated and evenly spread into the mold, and a powder spreading device is used complete, combine figure 1 Instructions The powder spreading device of this embodiment is composed of a mold base 1, a mold cylinder 2, an extension pipe 3 and a stirring rod 4. The stirring rod 4 has multiple sets of stirring blades 4-1, and one end of the mold cylinder 2 is sealed. On the flange of the mold base 1, the other end of the mold cylinder 2 is in sealing communication with one end of the extension pipe 3, and the stirring rod 4 is inserted from the other end of the extension pipe 3, so that the working end of the stirring rod 4 is inserted into the end of the extension pipe 3. One port. Other steps and parameters are the same as those in Embodiment 1.

[0066] In this em...

specific Embodiment approach 3

[0067] Embodiment 3: This embodiment differs from Embodiment 2 in that the height h of the extension tube in the powder spreading device is 2 to 4 times the height H of the mold cylinder. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com