Characterization method of pore structure of porous concrete based on CT (Computerized Tomography) technology

A technology of porous concrete and CT technology, applied in the field of measurement, can solve problems such as difficulty in ensuring accuracy, limited data acquisition points, and damage to the pore structure of concrete, and achieve the effects of simple test method, short detection time, and accurate characterization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

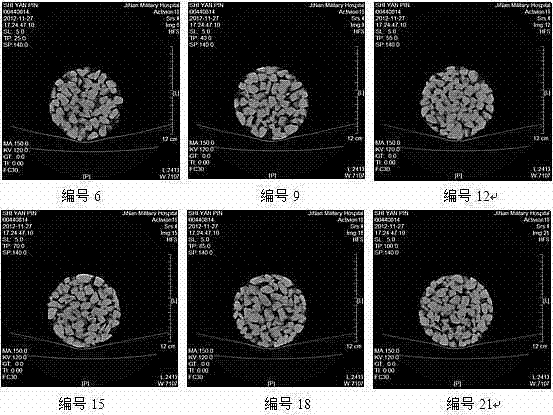

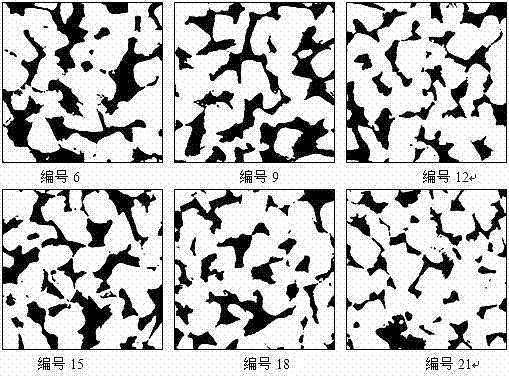

[0025] The basalt coarse aggregate with a particle size of 9.5~16.0mm was screened out through square holes, and the porous concrete was prepared according to the water-cement ratio of 023 and the cement-to-bone ratio of 1 / 6.5, and was molded with a φ110mm×150mm PVC pipe, and demolded after curing for 7 days. Test piece samples such as figure 1 shown. Two-dimensional tomographic images of porous concrete (such as figure 2 As shown, the two-dimensional tomographic images obtained by CT scanning are rich. Due to the limited space of the patent, 6 images are selected here to introduce the processing process in detail, and the rest of the image processing methods are similar), and the scanning thickness is 5mm. Using ImageJ TM The image processing software performs black and white binary processing on the CT image (such as image 3 ), calculate the area of the area represented by the pores to obtain the plane porosity (such as Figure 4 ), and then filter out micropores wit...

Embodiment 2

[0027] Limestone coarse aggregates with a particle size of 19.0-26.5 mm were screened out using square holes, and porous concrete was prepared according to the absolute volume method, with a target porosity of 26%. The PVC pipe of φ110mm×150mm was used to form it, and after curing for 7 days, it was removed from the mold to obtain the test piece sample. A 320-row advanced PET / CT machine from Germany's Siemens was used to scan to obtain a two-dimensional tomographic image of porous concrete. Using ImageJ TM After the image processing software performs black and white binary processing on the CT image, calculate the area of the area represented by the pores to obtain the plane porosity, then filter out micropores with a diameter less than 1mm, and then import the data into the statistical analysis software to obtain the effective pore size and pore size distribution (Such as Figure 7 ) and the longitudinal distribution of planar porosity (such as Figure 8 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com