Preparation method of high thermostable eight bromo ether

A technology of high thermal stability and octabromoether is applied in the field of preparation of high thermally stabilized octabromoether, can solve the problems of complicated octabromoether process and high cost of octabromoether treatment, achieves a significant initial decomposition temperature, avoids accelerated decomposition, The effect of increasing the initial decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

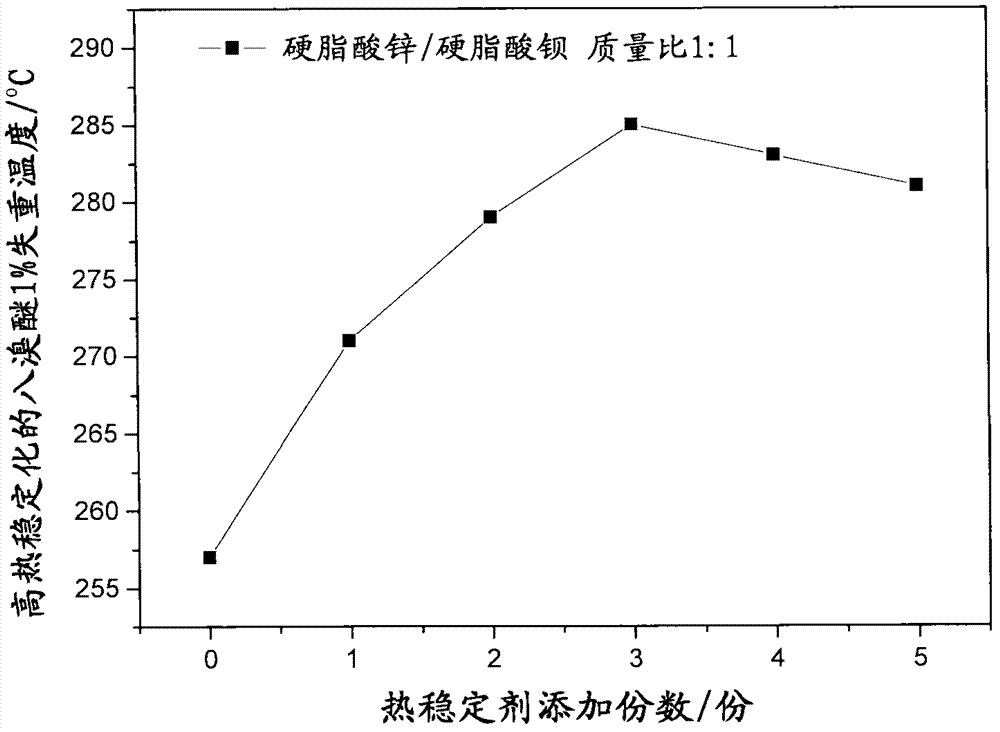

[0018] Example 1 Weigh 100 parts of octabromoether, configure 3 parts of zinc stearate and barium stearate according to the mass ratio of 1:1, configure 2 parts of antioxidant 168 and antioxidant 1010 according to the ratio of 2:1, add Put 1 part of coupling agent KH570 into a high-speed mixer and stir evenly. The initial decomposition temperature of 1% weight loss of the test material is 285°C.

Embodiment 2

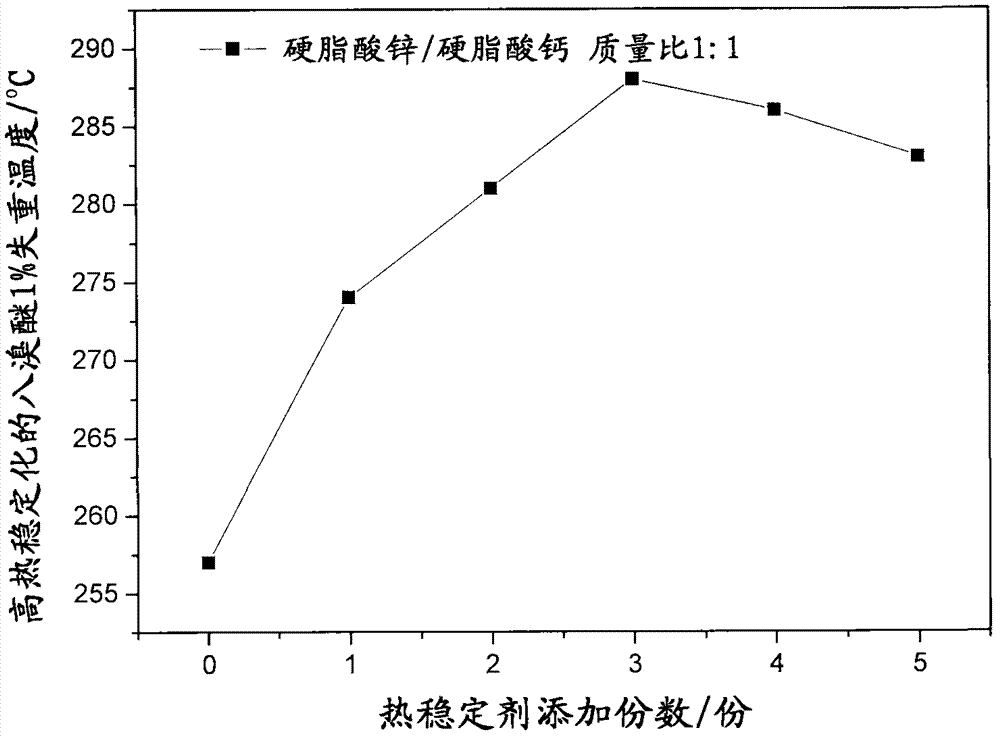

[0019] Example 2 Weigh 100 parts of octabromoether, configure 3 parts of zinc stearate and calcium stearate according to the mass ratio of 1:1, configure 2 parts of antioxidant 168 and antioxidant 1010 according to the ratio of 2:1, add Put 1 part of coupling agent KH570 into a high-speed mixer and stir evenly. The initial decomposition temperature of 1% weight loss of the test material is 288°C.

Embodiment 3

[0020] Example 3 Weigh 100 parts of octabromoether, configure 1 part of zinc stearate and calcium stearate according to the mass ratio of 1:1, prepare 1 part of antioxidant 168 and antioxidant 1010 according to the ratio of 2:1, add Put 1 part of coupling agent KH550 into a high-speed mixer and stir evenly. The initial decomposition temperature of 1% weight loss of the test material is 276°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com