Process for preparing isooctyl thioglycolate

A technology of isooctyl thioglycolate and isooctyl acetate, which is applied in the field of preparation of isooctyl thioglycolate, can solve the problems of high production cost, high cost of thioglycolic acid, easy oxidation and thermal decomposition of thiol groups, and achieve recovery Effects of shorter time, higher productivity, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

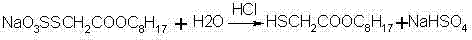

Image

Examples

Embodiment 1

[0027] Example 1. A kind of preparation technology of isooctyl thioglycolate, its step is as follows:

[0028] (1) Esterification reaction: first add chloroacetic acid to the reaction kettle, then add isooctyl alcohol and concentrated sulfuric acid as a catalyst, and perform esterification reaction while distilling water under reduced pressure. After the reaction, wash with sodium carbonate and saline solution. Then wash with water, wash the waste water to the waste water collection tank, and the esterification product to the esterification storage tank; open the valve at the bottom of the water separator, pour the water into the waste water tank, and put the remaining ester-alcohol mixture into the next batch; among them: chloroacetic acid , The weight ratio of isooctyl alcohol to catalyst is 800:1000:8;

[0029] (2) Mercaptolation reaction: Measure the esterified product in the esterified product storage tank into the esterified product metering tank and put it into the rea...

Embodiment 2

[0032] Example 2. A kind of preparation technology of isooctyl thioglycolate, its step is as follows:

[0033] (1) Esterification reaction: first add chloroacetic acid to the reaction kettle, then add isooctyl alcohol and concentrated sulfuric acid as a catalyst, and perform esterification reaction while distilling water under reduced pressure. After the reaction, wash with sodium carbonate and saline solution. Then wash with water, wash the waste water to the waste water collection tank, and the esterification product to the esterification storage tank; open the valve at the bottom of the water separator, pour the water into the waste water tank, and put the remaining ester-alcohol mixture into the next batch; among them: chloroacetic acid , the weight ratio of isooctyl alcohol and catalyst is 800: 1150: 10;

[0034] (2) Mercaptolation reaction: Measure the esterified product in the esterified product storage tank into the esterified product metering tank and put it into the...

Embodiment 3

[0037] Example 3. A kind of preparation technology of isooctyl thioglycolate, its step is as follows:

[0038] (1) Esterification reaction: first add chloroacetic acid to the reaction kettle, then add isooctyl alcohol and concentrated sulfuric acid as a catalyst, and perform esterification reaction while distilling water under reduced pressure. After the reaction, wash with sodium carbonate and saline solution. Then wash with water, wash the waste water to the waste water collection tank, and the esterification product to the esterification storage tank; open the valve at the bottom of the water separator, pour the water into the waste water tank, and put the remaining ester-alcohol mixture into the next batch; among them: chloroacetic acid , The weight ratio of isooctyl alcohol to catalyst is 800:1090:9;

[0039](2) Mercaptolation reaction: Measure the esterified product in the esterified product storage tank into the esterified product metering tank and put it into the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com