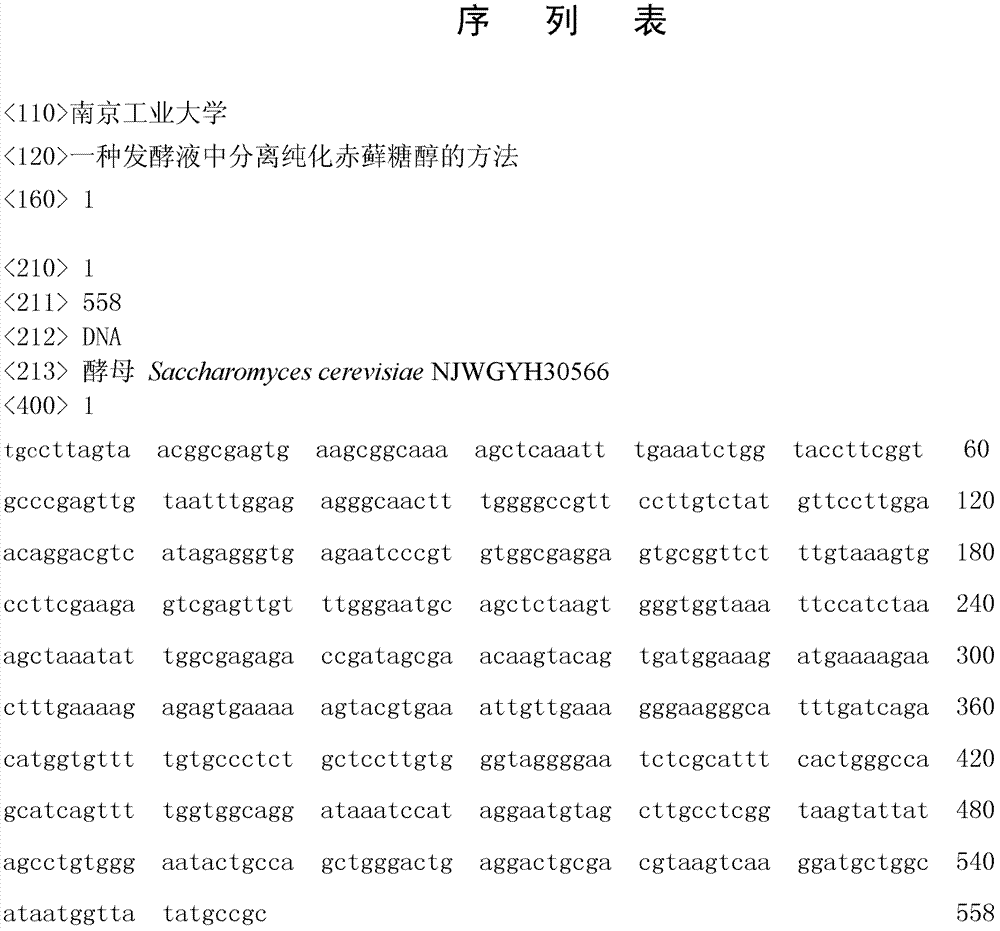

Method for separating and purifying erythritol from yeast fermentation broth

A technology for erythritol and yeast fermentation, applied in the field of bioengineering, can solve the problems of inability to improve the quality of erythritol, and achieve the effects of low cost, convenient operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

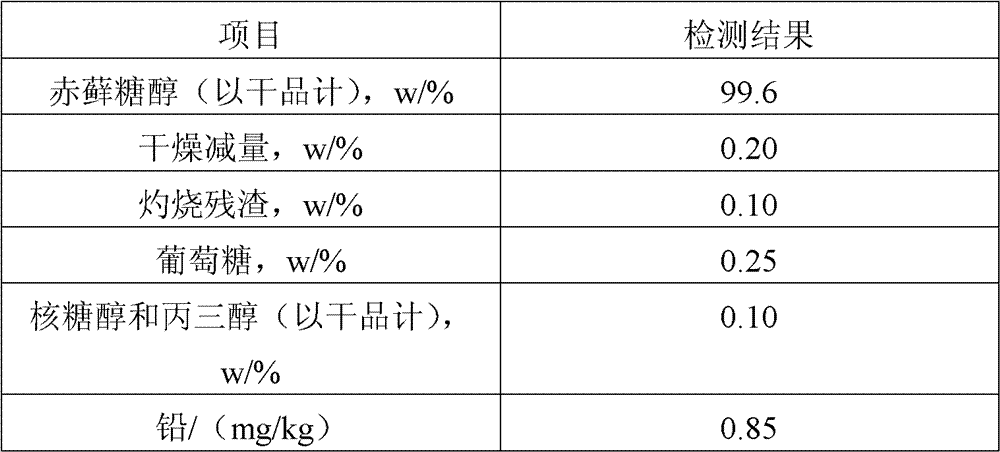

Embodiment 1

[0038] (1) Fermentation broth pretreatment: Centrifuge the erythritol fermentation broth at 4000rpm for 10 minutes to obtain bacteria and supernatant, heat the supernatant to 80°C, keep the temperature for 20min, and set aside;

[0039] (2) Supernatant treatment: The supernatant treated in step (1) is first filtered through a microporous membrane made of polyethersulfone with a pore size of 0.22 μm, and then filtered through an ultrafiltration membrane made of polyethersulfone with a molecular weight cut-off of 3000. Membrane ultrafiltration to obtain filtrate;

[0040] (3) Desalination: The filtrate of step (2) is first passed through a 001×8 strong acidic cation exchange resin column, and then passed through a 201×7 strong basic anion exchange resin column. The anion and cation exchange resins are packed separately, and the height of the resin packed column is 30cm in diameter, 3cm in diameter, and 30°C column temperature, collect the desalted column liquid;

[0041] (4) Co...

Embodiment 2

[0044] (1) Fermentation broth pretreatment: Centrifuge the erythritol fermentation broth at 4500 rpm for 20 minutes to obtain bacteria and supernatant, heat the supernatant to 85°C, keep the temperature for 10 minutes, and set aside;

[0045] (2) Supernatant treatment: The supernatant treated in step (1) is first filtered through a microporous filter membrane made of polytetrafluoroethylene with a pore size of 0.45 μm, and then filtered with a polycarbonate filter with a molecular weight cut-off of 2000. Ultrafiltration membrane ultrafiltration to obtain filtrate;

[0046] (3) Desalination: The filtrate of step (2) is first passed through a 7320 strong acidic cation exchange resin column, and then through a 201×4 strong basic anion exchange resin column. The anion and cation exchange resins are packed separately, and the height of the resin packed column is 35cm , the diameter is 3cm, the column temperature is 35°C, and the desalted column solution is collected;

[0047] (4) ...

Embodiment 3

[0050] (1) Fermentation broth pretreatment: Centrifuge the erythritol fermentation broth at 5000 rpm for 15 minutes to obtain bacteria and supernatant, and heat the supernatant to 90° C., keep the temperature for 15 minutes, and set aside;

[0051] (2) Supernatant treatment: The supernatant treated in step (1) is first filtered through a microporous filter membrane made of polyethersulfone with a pore size of 0.45 μm, and then ultrafiltered with a polyamide material with a molecular weight cut-off of 3500 Membrane ultrafiltration to obtain clarified liquid;

[0052] (3) Desalination: The clarified solution of step (2) is first passed through a 001×7 strong acid cation exchange resin column, and then through a 201×7 strong basic anion exchange resin column. The anion and cation exchange resins are packed separately, and the resin is packed into a column The height is 40cm, the diameter is 3.5cm, the column temperature is 40°C, and the desalted column liquid is collected;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com