Calcination and flash drying cyclic energy saving technology for intermediate wet carbonate from soft magnetic manganese zinc iron composite material prepared through precipitation method

A technology of flash drying and flash dryer, which is applied in the field of preparation of magnetic material raw materials, which can solve the problems of difficult temperature balance control, uneven material moisture, and non-environmental protection, so as to achieve stable burning loss and overcome uneven heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Produce 10.5 tons of co-sedimented powder (carbonate) in the tenth tank, with a water content of 35%.

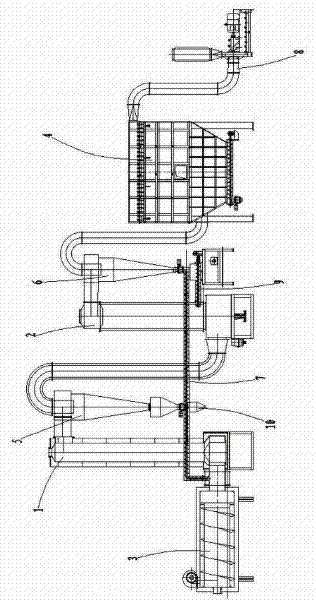

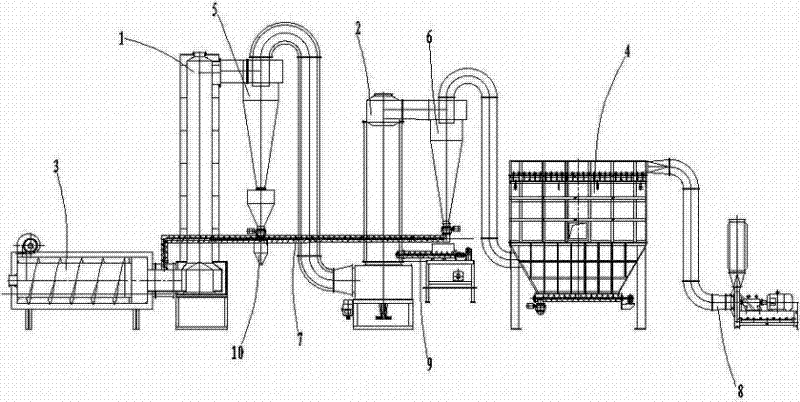

[0016] A. Set up a calcination and flash drying cycle energy-saving system. The dynamic calciner 1 and the flash dryer 2 are connected through the first cyclone dust collector 5, and the flash dryer 2 is connected through the second cyclone dust collector 6. Bag vacuum cleaner 4; the bottom of the dynamic calciner 1 is connected to the hot blast stove 3, the top of the dynamic calciner 1 is connected to the tangential inlet of the first cyclone dust collector 5, and the top outlet of the first cyclone dust collector 5 is connected to the flash drying The bottom inlet of the flash dryer 2 is connected, the top of the flash dryer 2 is connected to the tangential inlet of the second cyclone dust collector 6, and the top outlet of the second cyclone dust collector 6 is connected to the bag vacuum cleaner 4; the second cyclone dust collector 6. The outlet at the lower end ...

Embodiment 2

[0019] Produce 8.3 tons of co-sedimented powder (carbonate) in the tenth tank, with a water content of 40%.

[0020] The process is the same as that in Implementation 1, except that the temperature of the waste heat airflow input into the flash dryer 2 after the dynamic calciner 1 is calcined is 220°C; the heat provided by the hot blast stove 3 is 820°C, and the sieve on the 160-mesh sieve is 0.6%<1%, dark brown powder is obtained.

Embodiment 3

[0022] Produce 13.3 tons of co-sedimented powder (carbonate) in the tenth tank, with a water content of 40%.

[0023] The process is the same as that in Implementation 1, except that the temperature of the waste heat airflow input into the flash dryer 2 after the dynamic calciner 1 is calcined is 220°C; the heat provided by the hot blast stove 3 is 820°C, and the sieve on the 160-mesh sieve is 0.6%<1%, dark brown powder is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com