Continuous processing method for diffuser plate with surface microstructure

A processing method and diffusion plate technology, which are applied in chemical instruments and methods, lamination auxiliary operations, lamination and other directions, can solve the problems of short contact time between the plate and the roller, insufficient pressure holding time, and poor processing of the roller. The effect of processing, processing cost reduction, and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

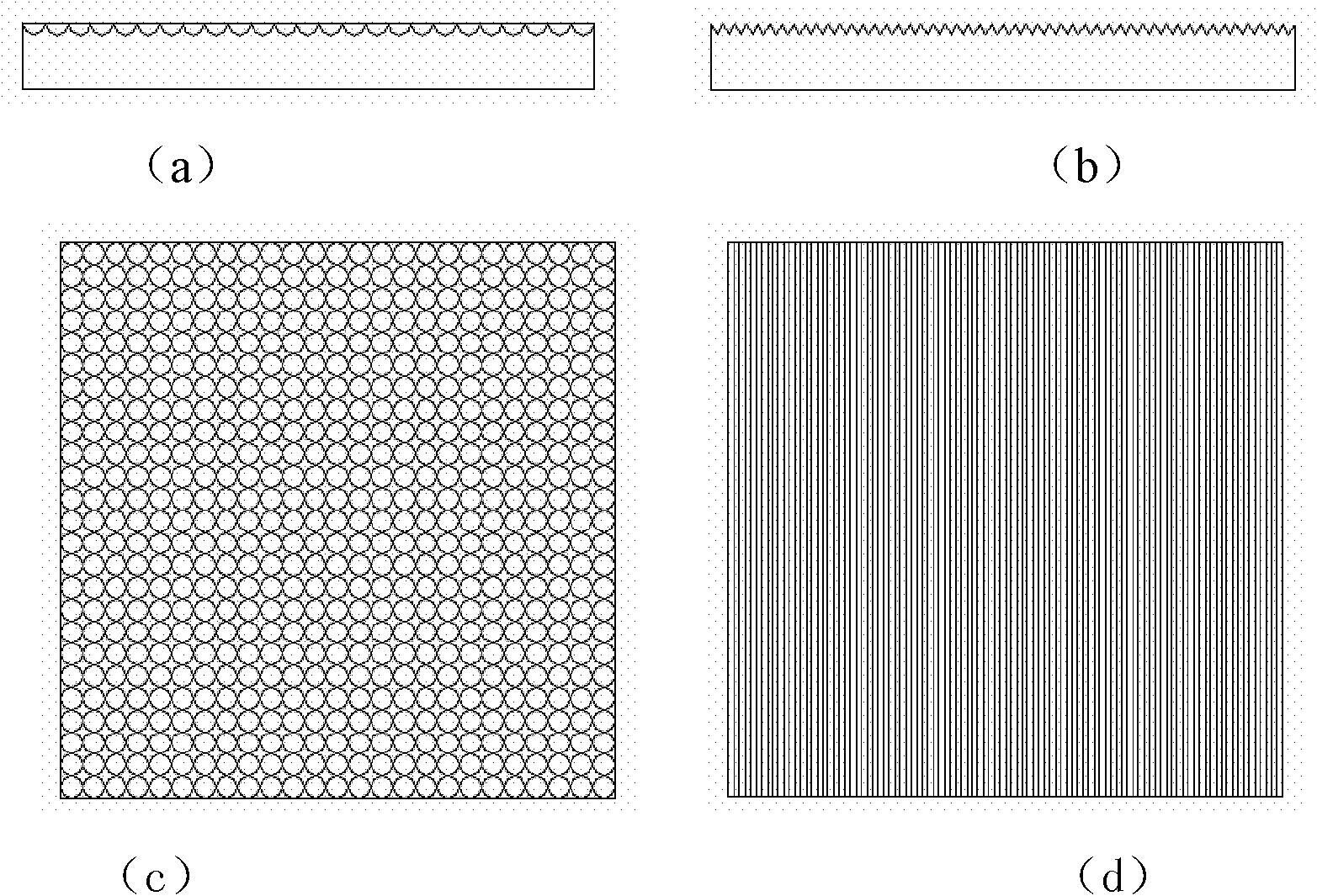

[0030] Diffusion plates of any size can be processed by this processing method, and the processing of a diffusion plate for a 17-inch liquid crystal display with a length, width, and height of 5, 37, and 34 cm is taken as an example for illustration. Extrude a PMMA plate with a width of 37 cm and a thickness of 2 mm with an ordinary extruder.

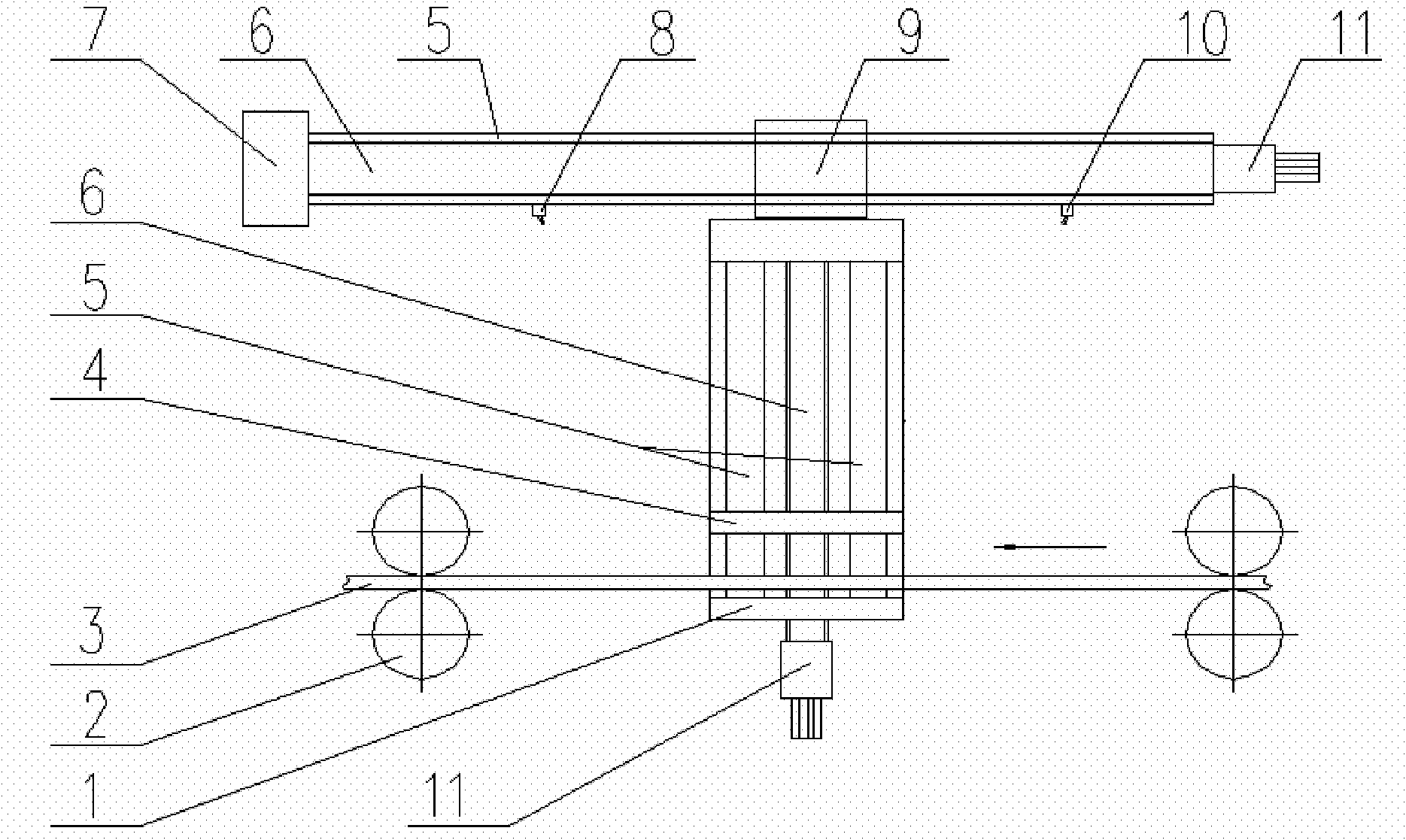

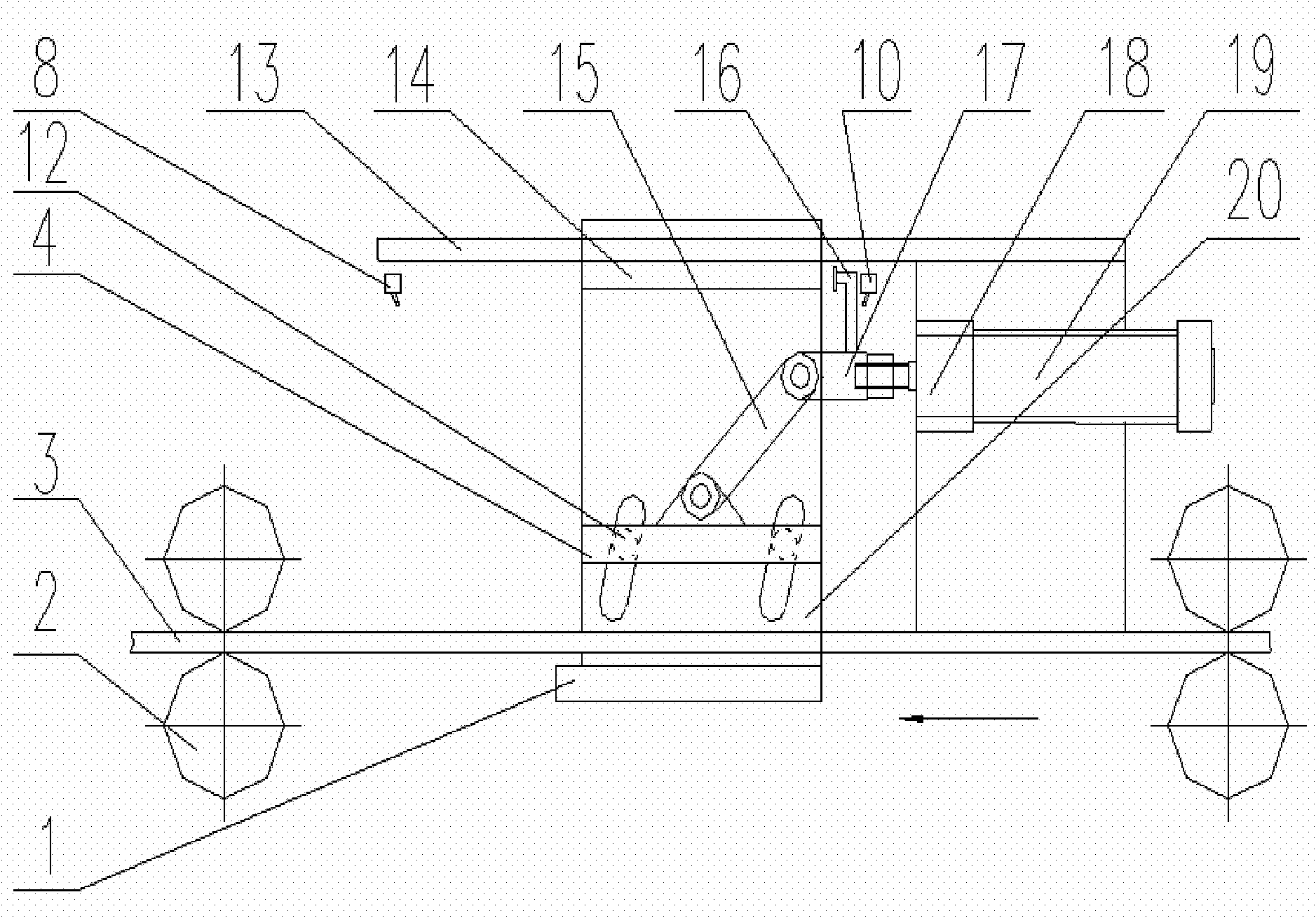

[0031]If device 1 is used, the operation steps are as follows: first, splice the mold blocks into a width of 36 cm, and install them at the designated positions. Use an extruder to extrude a single-layer or multi-layer diffusion plate substrate 3, and the tractor 2 will pull the substrate to the imprinting area, which is the traction process; the motor 11 drives the screw 5 to rotate, and the upper mold 4 moves downward to press the substrate. On the lower mold 1, copy the microstructure on the mold to the uncooled substrate, which is the mold clamping process; the lead screw 5 of the horizontal screw drive system rotates to drive the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com