Catalyst for preparing olefins with same carbon atom number by dehydrogenizing alkane mixtures of C4 and above, and preparation method and application thereof

A kind of alkane mixture and catalyst technology, which is applied in the direction of physical/chemical process catalysts, hydrocarbons, hydrocarbons, etc., can solve the problems of high difficulty and weak conversion ability of heavy oil, so as to save energy, avoid strong endothermic process, and promote The effect of industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

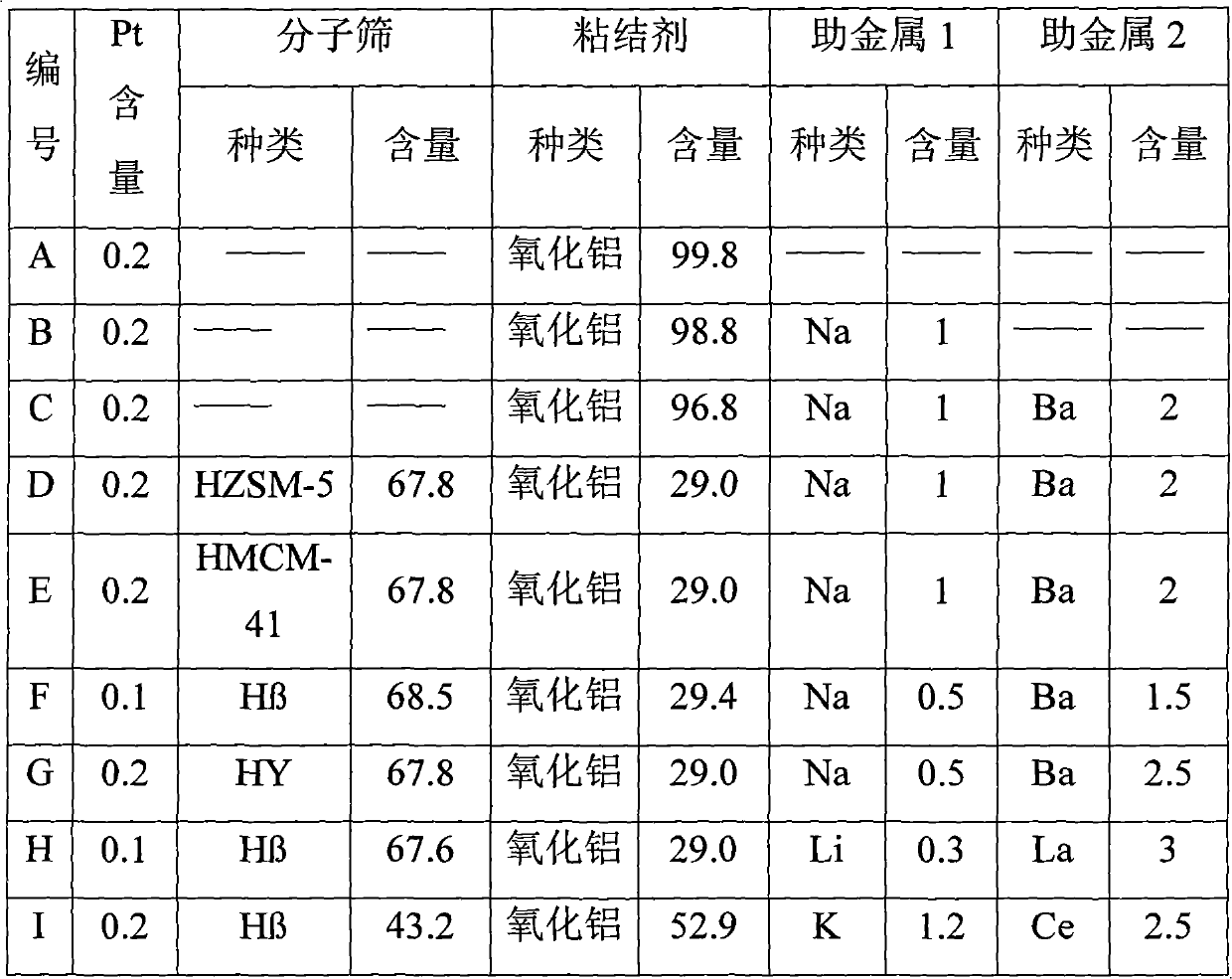

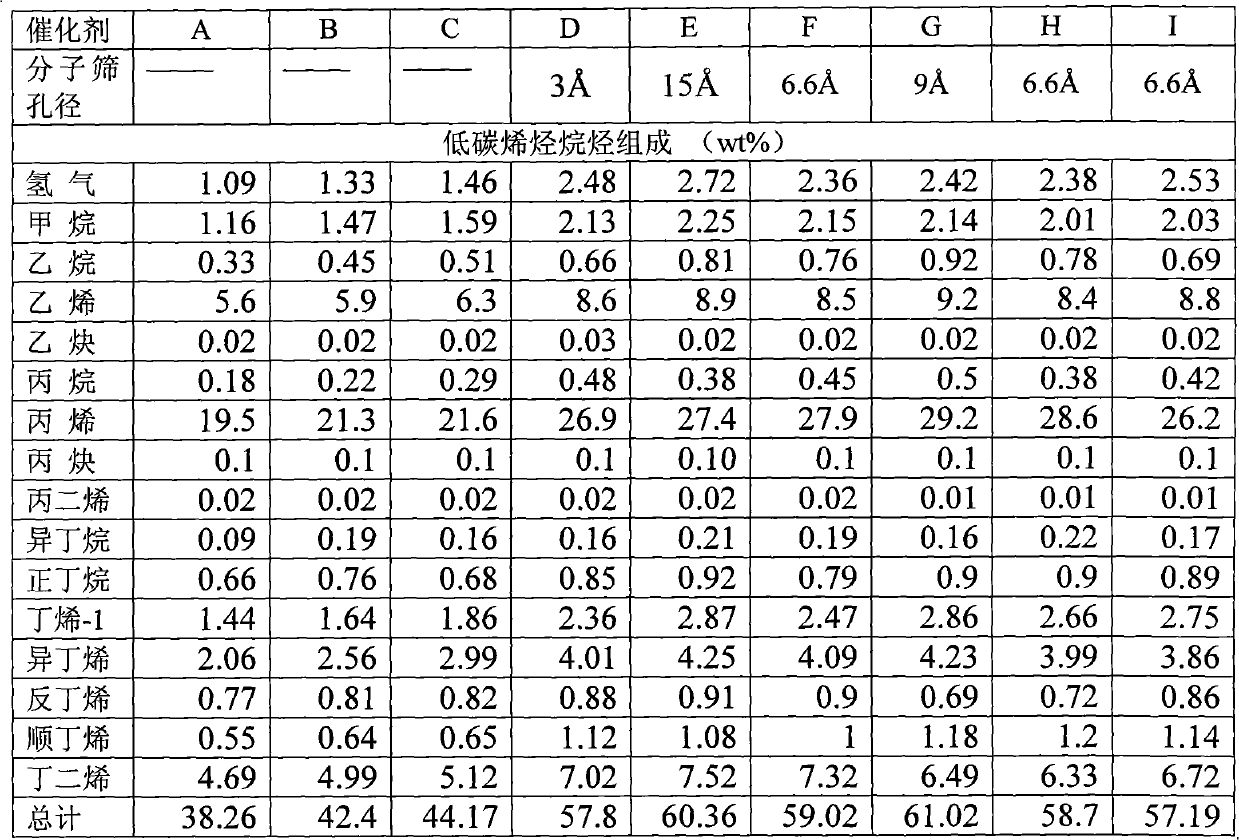

Embodiment 1

[0050] Take 6g of alumina powder (Jiangyan Auxiliary Factory, γ-type) and 14g of HMCM-41 molecular sieve (Nankai University Catalyst Factory) after molding and roasting (the weight ratio is 3:7), impregnated in 0.2mol / L NaNO 3 In 44ml of aqueous solution, take it out and dry it at 120°C for 2 hours and bake it at 500°C for 2 hours; then dip it into the hydrochloric acid solution in which chloroplatinic acid is dissolved, the impregnation solution is 55ml of a solution with a concentration of 0.0074gPt / L, take it out and dry it at 120°C , 450 ° C air treatment for 2 hours; then soaked in 0.1mol / LBa (NO 3 ) 2 In 30ml of hydrochloric acid solution, take it out, dry it at 120°C for 2 hours and bake it at 500°C for 2 hours; obtain catalyst E.

Embodiment 2

[0052] Take 6g of alumina powder (Jiangyan Auxiliary Factory, γ-type) and 14g of Hβ molecular sieve (Nankai University Catalyst Factory) after molding and roasting (weight ratio is 3:7), impregnated in 0.1mol / L NaNO 3 In 44ml of aqueous solution, take it out and dry it at 120°C for 2 hours and bake it at 500°C for 2 hours; then immerse it in the hydrochloric acid solution in which chloroplatinic acid is dissolved. Dry for 2 hours, 450 ℃ air treatment for 2 hours; then impregnated in 0.05mol / L Ba(NO 3 ) 2 44ml of hydrochloric acid solution, took it out, dried it at 120°C for 2 hours and calcined at 500°C for 2 hours; Catalyst F was obtained.

Embodiment 3

[0054] Take 6g of alumina powder (Jiangyan Auxiliary Factory, γ-type) and 14g of HY molecular sieve (Nankai University Catalyst Factory) after molding and roasting (weight ratio is 3:7), impregnated in 0.1mol / L NaNO 3 In 44ml of aqueous solution, take it out and dry it at 120°C for 2 hours and bake it at 500°C for 2 hours; then immerse it in the hydrochloric acid solution in which chloroplatinic acid is dissolved. Dry for 2 hours, 450 ℃ air treatment for 2 hours; then impregnated in 0.1mol / L Ba(NO 3 ) 2 37ml of hydrochloric acid solution, after taking it out, it was dried at 120°C for 2 hours and calcined at 500°C for 2 hours; Catalyst G was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com