Activated carbon for solvent recovery produced from wood materials and preparation method thereof

A wood material, activated carbon technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of increasing production costs and rising product prices, and achieve lower prices and higher adsorption capacity. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

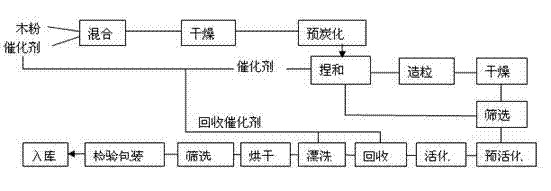

[0018] The present invention mainly comprises the following steps:

[0019] (1) Mixing of raw materials: Put the wood powder and catalyst in proportion to the environment of 80-125 ℃ and stir for 20~40 minutes until mixed; the mixing ratio is that the weight ratio of wood powder and catalyst is 1:0.8- 2.0.

[0020] The wood powder in the raw material is the wood powder that mixes one or more of coconut shells, apricot shells, tea seed shells, industrial throwing flowers, and sawdust to 20-100 meshes and has a moisture content of 5-20%. Described catalyzer is any one solution in phosphoric acid, zinc chloride, calcium chloride, sulfuric acid, boric acid, potassium dichromate, potassium permanganate, and the concentration of solution is 30-70%; Described catalyzer is with phosphoric acid, When zinc chloride is used as a catalyst, the product obtained has the best performance.

[0021] (2) Pre-carbonization (curing): Dry the mixture in step (1) at 80-125°C for 10-15 hours. Car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com