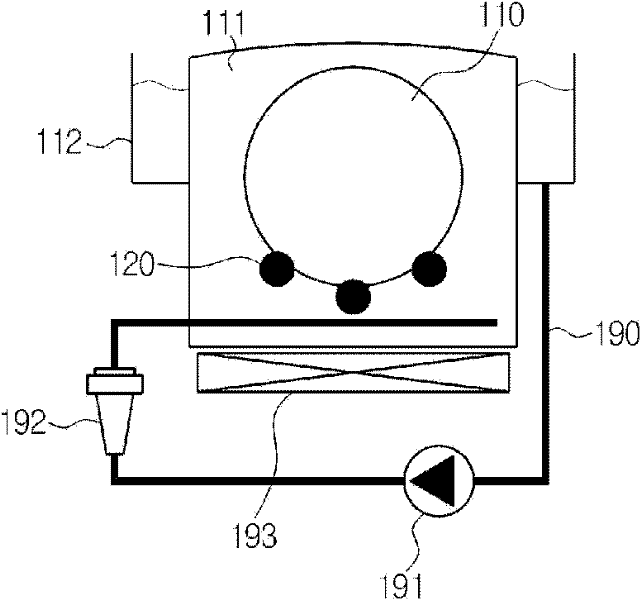

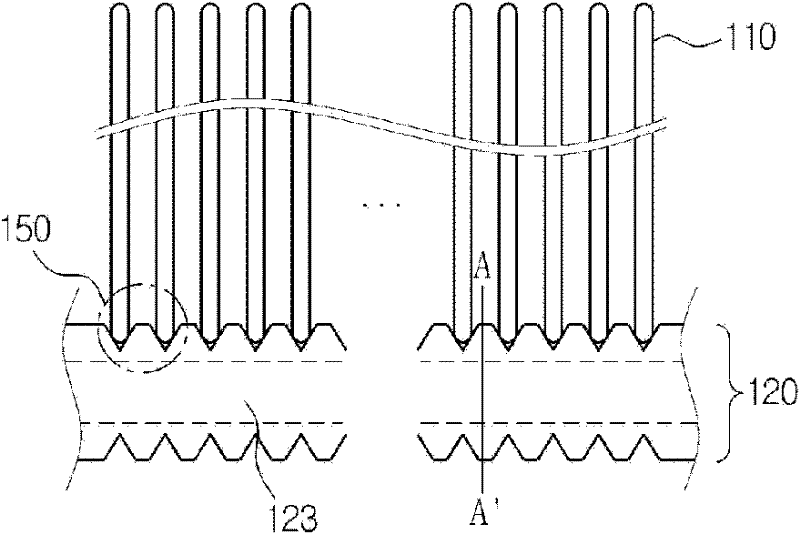

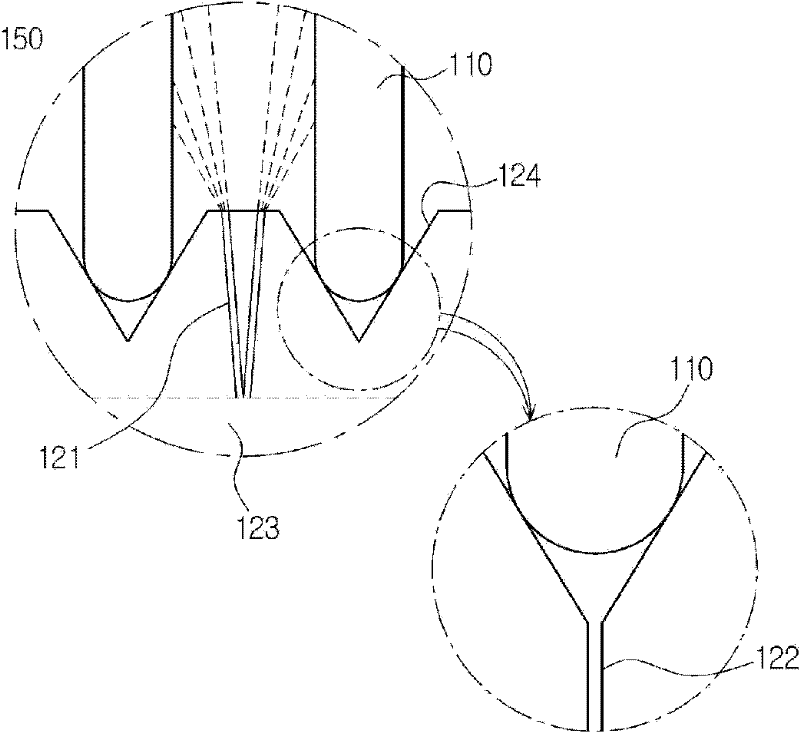

Apparatus and method for wet-processing object, and fluid diffusion plate and barrel used therein

A technology for dealing with fluid and fluid diffusion, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve problems such as volume increase, complexity, and etching fluid interference, and achieve the effect of compact design, manufacturing, and uniform processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Before the description, it should be understood that the terms used in the description and the appended claims should not be construed as limited to the general meaning and dictionary meaning, but should be based on the meaning and concept of the technical aspects of the present invention, and based on the inventor's permission to explain the principles in order to properly qualify the terminology used for the best interpretation. Accordingly, the descriptions presented here are only preferred examples for illustrative purposes, and are not intended to limit the scope of the present invention, so it should be understood that other equivalents can be made thereto without departing from the spirit and scope of the present invention. and modify.

[0033] In addition, although it is assumed in the following description that the object to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com