Structured electrode for ceramic sensor elements

A technology of sensor element and structured part, applied in the field of known sensor element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

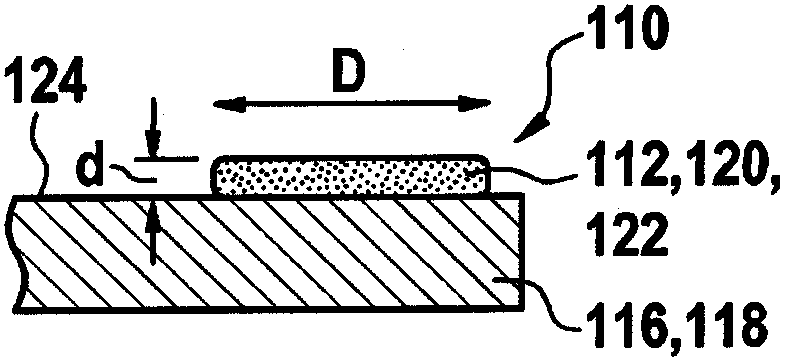

[0050] exist Figure 1A and 1B An example of a conventional sensor element 110 is schematically shown in . Only one electrode 112 of the sensor element 110 and the lead 114 leading to this electrode 112 are shown here (only in the Figure 1A visible in). here Figure 1A Electrode 112 and sensor element 110 are shown in top view, while Figure 1B A sectional view of sensor element 110 is shown from the side.

[0051] Electrode 112 is coated on solid electrolyte layer 116 which includes solid electrolyte material 118 . For example, the solid electrolyte material may be yttrium stabilized zirconia (YSZ), where typically 5.5 mole percent of YSZ is used. Electrode 112 is applied to solid electrolyte layer 116 , which may be formed, for example, as a thin-film layer. Electrode 112 is designed, for example, as a platinum-YSZ cermet electrode and generally has a porous structure. For the manufacture of such electrodes 112 typically an electrode paste is used which has a metallic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com