Precoated aluminum plate

A technology of pre-coating and aluminum plate, which is applied in the direction of coating, device for coating liquid on the surface, special surface, etc. It can solve the problems such as poor bonding of aluminum plate, achieve the expansion of manufacturing process, improve deep drawing formability, and improve operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

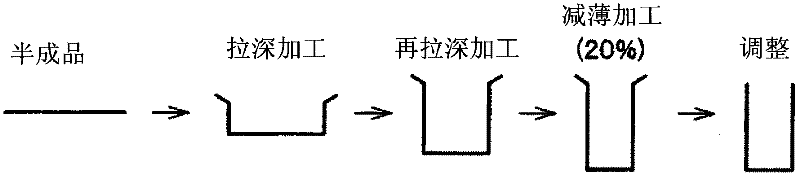

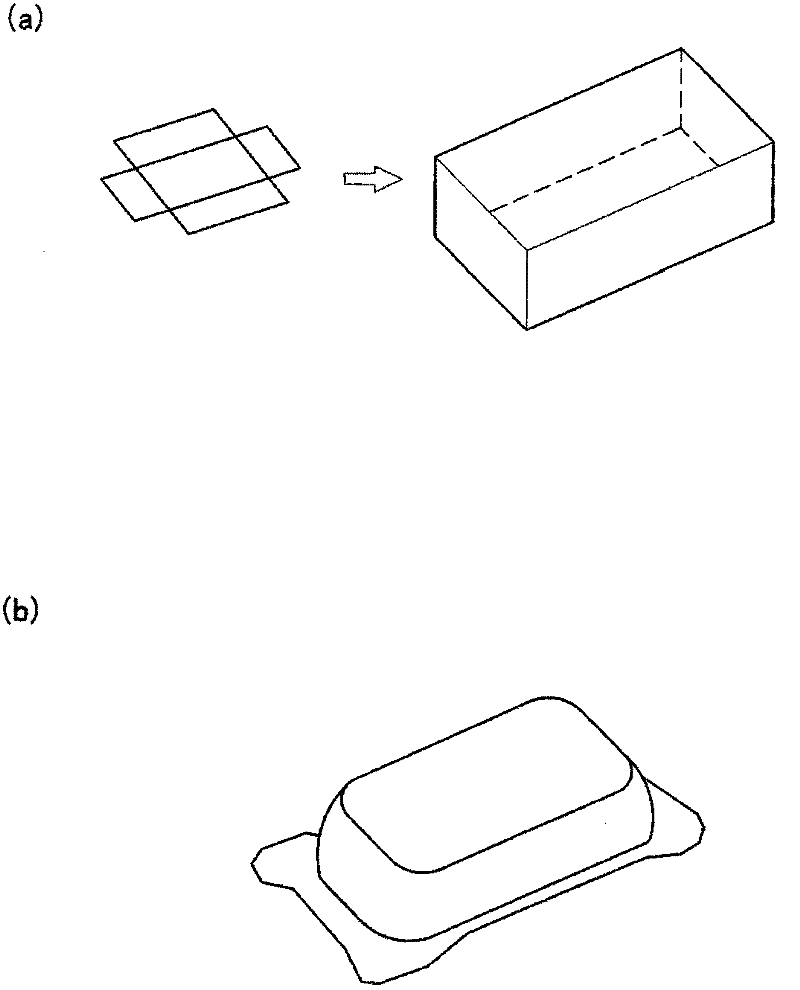

[0078] Hereinafter, the best mode of the precoated aluminum sheet of the present invention will be specifically described with reference to appropriate drawings.

[0079] In the attached drawings, figure 1 It is a partial cross-sectional view schematically showing the structure of the precoated aluminum sheet of the present invention.

[0080] (pre-coated aluminum sheet)

[0081] like figure 1 As shown, a precoated aluminum plate 1 forms a precoated film 3 containing an intermolecularly crosslinked base resin 4 and fine particles 5 on the surface of an aluminum plate 2 . Here, the surface of the aluminum plate 2 refers to at least one surface of the aluminum plate 2 . Each configuration will be described below.

[0082] (aluminum plate)

[0083] The aluminum plate 2 of the present invention is made of aluminum or an aluminum alloy, and the aluminum plate (aluminum plate or aluminum alloy plate) 2 used in the present invention is not particularly limited, and can be sele...

no. 2 approach

[0126] (pre-coated aluminum sheet)

[0127] like figure 1 As shown, the pre-coated aluminum plate 1 of the present invention is a pre-coated aluminum plate 1 with a pre-coated film 3 formed on the outermost surface of the aluminum plate 2. The pre-coated film 3 is made of epoxy resin and non-yellowing isocyanate It is composed of a thermosetting resin (base resin) 4 that is intermolecularly cross-linked with a curing agent, and has a gel fraction of not less than 70% and not more than 92%. In addition, although the microparticles|fine-particles 5 are not an essential component (constitution) of this invention, but are preferably contained in the precoat film 3, it is shown in a figure. Here, the surface of the aluminum plate 2 means at least one surface of the aluminum plate 2 . Each configuration will be described below.

[0128] (aluminum plate)

[0129] Since it is the same as the first embodiment, description is omitted.

[0130] (pre-coated film)

[0131] The preco...

Embodiment

[0161] first embodiment

[0162] Next, the precoated aluminum plate of the present invention will be specifically described by comparing the examples satisfying the conditions of the present invention and the comparative examples not satisfying the conditions of the present invention.

[0163] (first embodiment)

[0164] In the first embodiment, the durability of the film in the cleaning step, which is an essential object of the present invention, was investigated for the precoated aluminum plate of the present invention.

[0165] When discussing the precoated aluminum plate of the present invention, as the aluminum plate used as a raw material, an alloy number A1100-H24 having a plate thickness of 0.3 mm was used. After alkali degreasing with a weak base degreasing agent, chromium phosphate treatment is performed as a base treatment. The condition of chromium phosphate treatment is 20mg / m2 in terms of chromium adhesion 2 . In addition, the mechanical properties of the alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arithmetic mean roughness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com