Pipe having grooved inner surface, apparatus for producing the same and method for producing the same

A manufacturing method and a manufacturing device technology, applied to the field of pipes with grooves on the inner surface, can solve problems such as inability to process, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

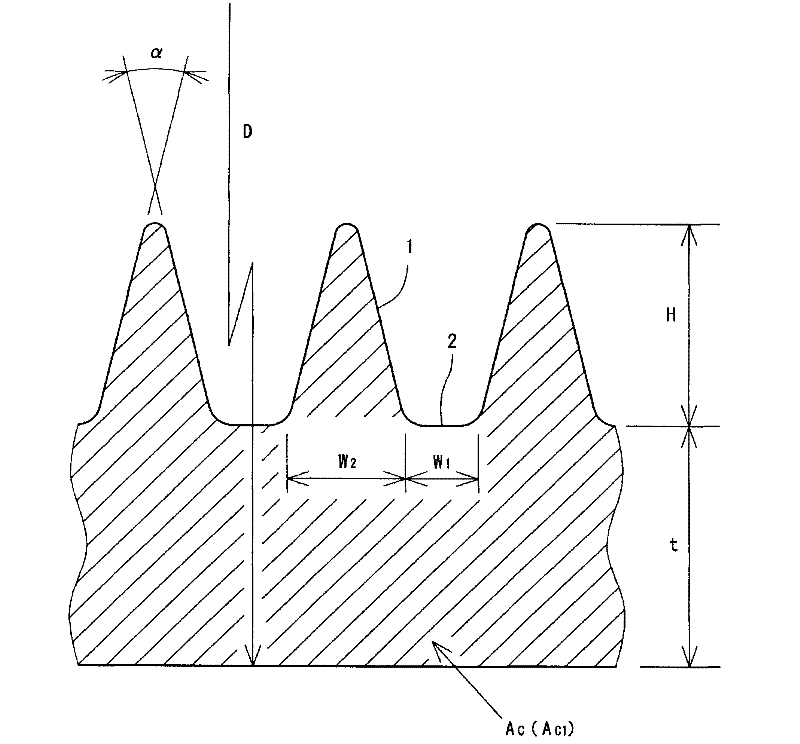

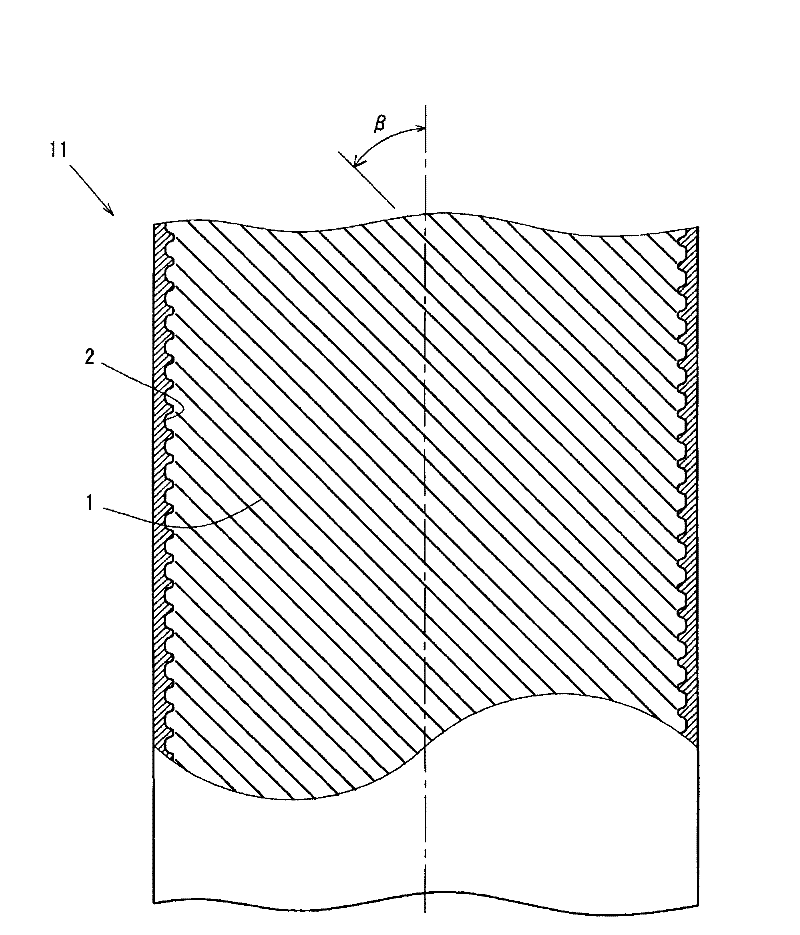

[0161] Embodiment 1 of the present invention is jointly described in conjunction with the following drawings.

[0162] The manufacturing method of the inner surface grooved pipe 11 in the present embodiment can use figure 1 The production apparatus 12 shown performs the production.

[0163] in addition, figure 1 It is an explanatory drawing of the manufacturing apparatus 12 of the inner surface grooved pipe in this Example.

[0164] The manufacturing device 12 is drawn from the drawing direction (stretching direction) ( figure 1 In the X direction) the upstream side to the downstream side is sequentially arranged to reduce the diameter part 13, the auxiliary drawing device 17, the groove processing part 14, and the trimming processing part 15, and the drawing device 16 is included on the further downstream side, and these configurations are continuous The inner surface grooved tube 11 is manufactured by processing the base tube 11a.

[0165] In detail, the manufacturing de...

Embodiment 2

[0256] Next, the manufacturing apparatus 101 and the manufacturing method of the inner grooved pipe of Example 2 will be described.

[0257] The manufacturing apparatus 101 of inner surface grooved pipe is arranged in this order from the upstream side with the diameter reduction device 120 for reducing the diameter of the base pipe 201 as the processing object 200, and the groove processing for performing groove processing on the inner surface of the reduced diameter pipe 202 after diameter reduction. Apparatus 140, and reel 160 of inner surface grooved tube 204 after drawing groove processing.

[0258] In addition, a conveyance assisting device 130 that assists in conveying the reduced diameter tube 202 in the conveyance direction of the groove processing device 140 is provided between the diameter reducing device 120 and the groove processing device 140 .

[0259] In addition, on the inner surface grooved pipe manufacturing device 101, the fixed diameter reducing device 120 ...

Embodiment 9

[0266] An embodiment of the present invention will be described together with the following drawings.

[0267] Figure 4 It is a configuration diagram showing an inner grooved tube manufacturing apparatus 101 of the second embodiment. Should Figure 4 A device for processing, a device for sensing, and a device for control are shown in . in addition, Figure 5 It is an explanatory diagram for explaining the load applied to the raw material, the drawing force for processing, the auxiliary conveying force, and the detected load in the inner grooved pipe manufacturing apparatus 101 .

[0268] When describing the processing device, from upstream to downstream, the respective processing parts of the diameter reducing device 120, the auxiliary conveying device 130, the groove processing device 140, and the finishing processing device 150 are arranged horizontally and in a straight line, and in the downstream A reel 160 that draws and winds the base pipe 201 in a straight line is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com