Astigmatism self-compensation solid laser

A solid-state laser, self-compensation technology, applied in the laser field, can solve the problems of increasing the laser cavity loss, increasing the complexity of the temperature control device, unfavorable laser efficiency, etc., to achieve conversion efficiency, broaden the stability range, and reduce cavity loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

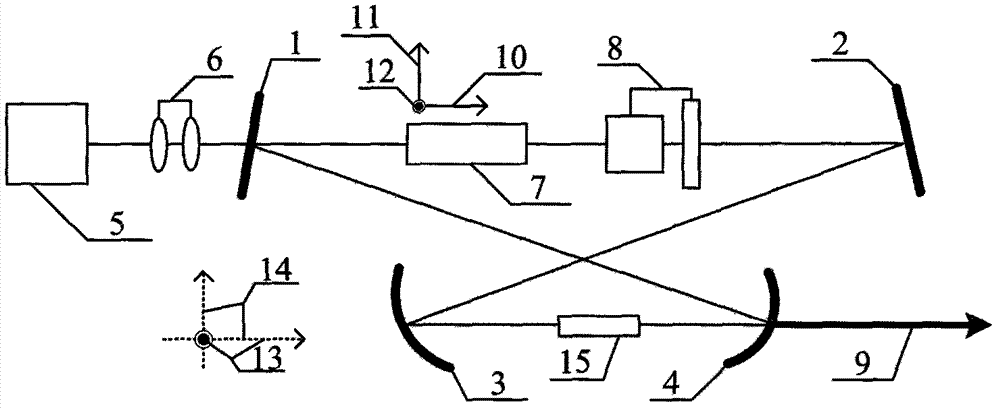

[0040] On the basis of the above-mentioned embodiments, a Q-switching element can be inserted into the resonant cavity to obtain a pulsed laser output.

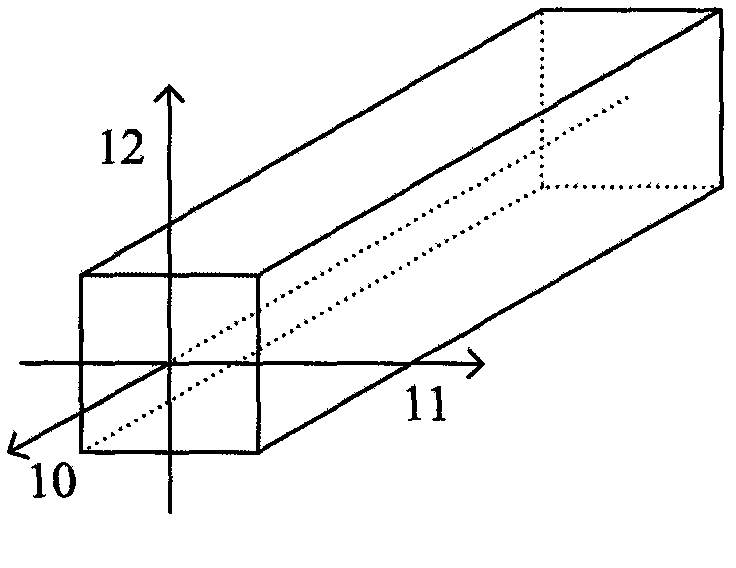

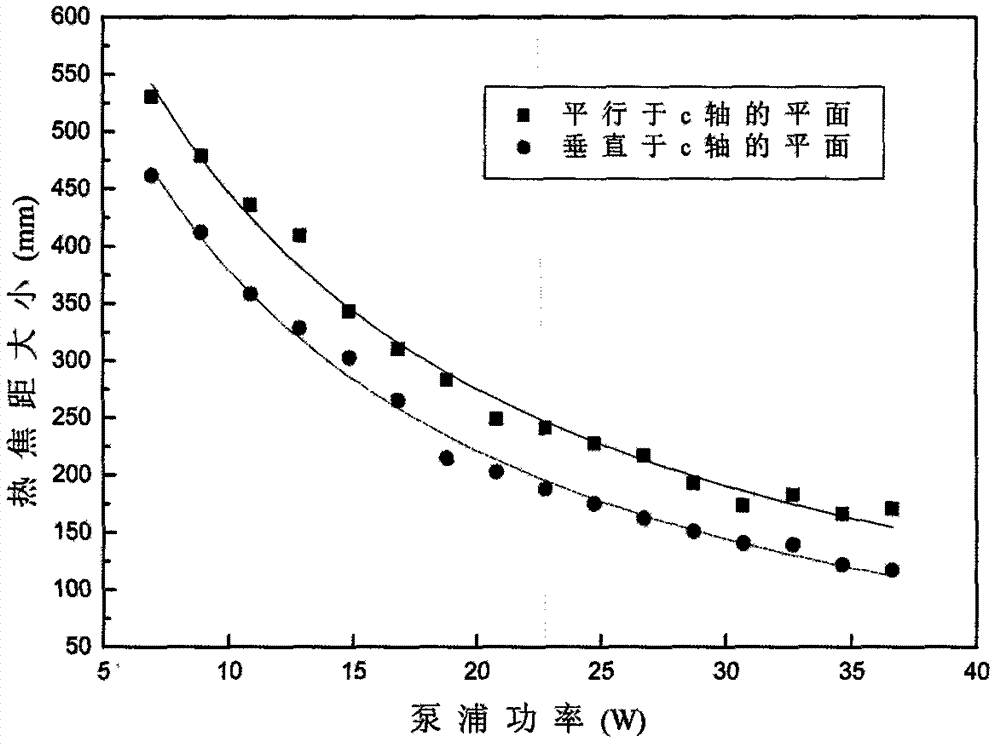

[0041] On the basis of the above embodiment, Nd:YLF crystal, Nd:KGW crystal, etc. can be selected as the gain medium 7 to compensate for the astigmatism formed by the resonant cavity.

[0042] On the basis of the above-mentioned embodiment, resonant cavities of other structures, such as V-shaped cavity, 6-mirror cavity, etc., can be selected to compensate each other with the thermal lens astigmatism of the gain medium 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com