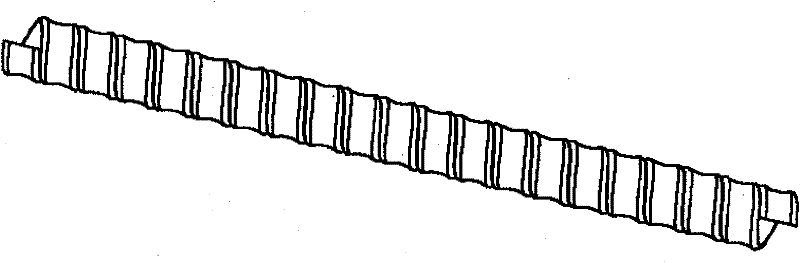

High-strength arc crankshaft spring hose

A spring hose, high-strength technology, used in hoses, shafts, flexible shafts, etc., can solve the problems of poor flexibility of solid spiral shafts or flat spiral hoses, achieve good homogenization, and avoid damage and folding. curved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Examples are given to illustrate the technical content of the present invention more clearly.

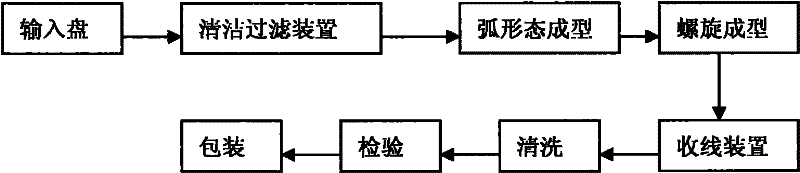

[0027] Production and processing flow chart of the present invention refers to attached figure 1 .

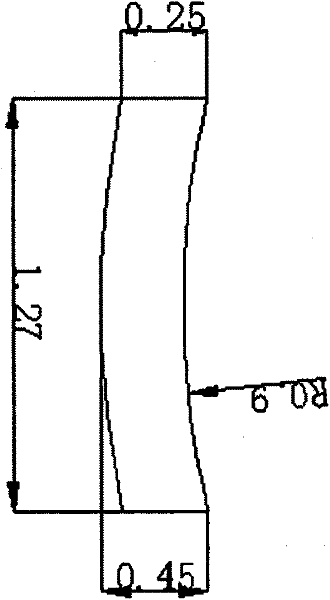

[0028] First of all, put the processed flat belt on the transmission drive disc lightly. After being processed into the required arc shape, it enters the special knife mold and feeds it into the reaming hole in a straight line, adjusts the three reamers, and starts spiral forming. During the process, the positions of the three reamers are constantly adjusted to make the spring hose reach the standard diameter and pitch. After ensuring that the pitch of the spring hose and the dimensions of the inner and outer diameters are stable, enter the take-up device, and refer to the attached drawing for the forming diagram of the crankshaft spring hose in the form of an arc. figure 2 , for a cross-section see the attached image 3 . Start the take-up reel, and wind the coiled spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com