Fireproof aluminum/plastic composite panel (APCP) with colored mirror face

A technology of aluminum-plastic composite board and mirror aluminum board, which is applied in the field of building decoration materials, can solve the problem of high fire protection requirements, and achieve the effect of light texture, hard surface and colorful colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

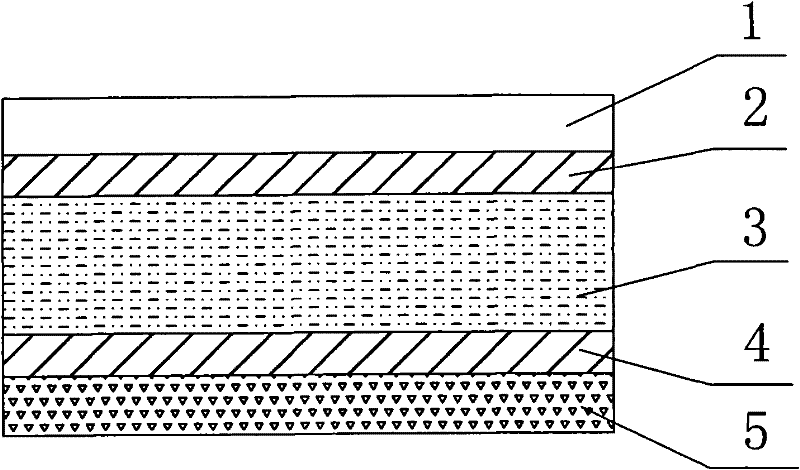

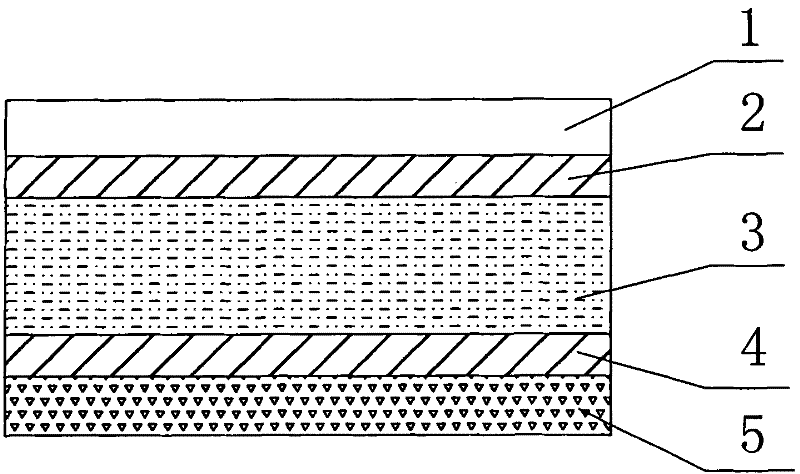

[0010] see figure 1 , figure 1 It is a schematic cross-sectional structure diagram of the colored mirror-surface fireproof aluminum-plastic composite board of the present invention. Depend on figure 1 It can be seen that the color mirror-surface fireproof aluminum-plastic composite board of the present invention is sequentially composed of a color mirror-surface aluminum plate 1, a first polymer adhesive film 2, an A2-grade non-combustible inorganic mineral-filled core layer 3, and a second polymer bonding film from top to bottom. The film 4 and the coated aluminum plate 5 are composed of five layers, and the surface of the colored mirror aluminum plate 1 is evenly distributed with irregular raised patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com