Mirror-face aluminum-plastic composite board

A technology of aluminum-plastic composite board and mirror aluminum board, which is applied in the field of building decoration materials, can solve the problem of low surface hardness and achieve the effect of light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

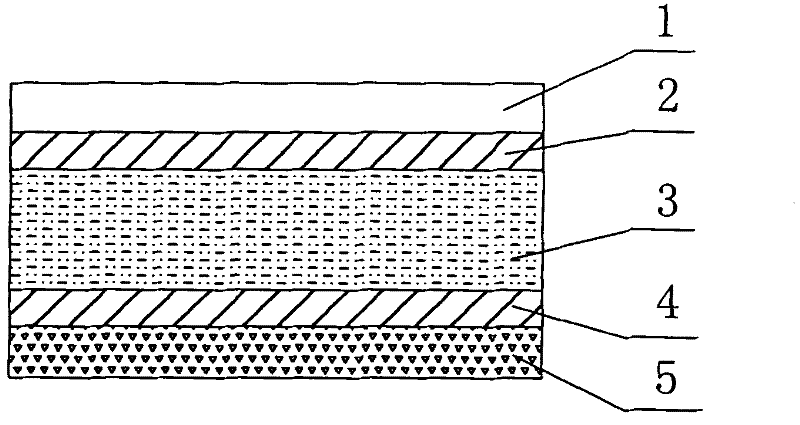

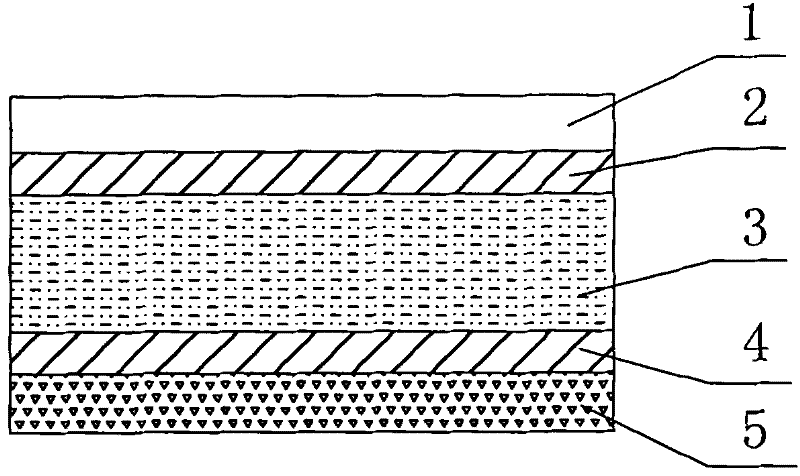

[0010] see figure 1 , figure 1 It is a schematic cross-sectional structure diagram of the mirror aluminum-plastic composite panel of the present invention. Depend on figure 1 It can be seen that the mirror-finish aluminum-plastic composite panel of the present invention consists of a mirror-finish aluminum plate 1, a first polymer adhesive film 2, a PE core layer 3, a second polymer adhesive film 4 and a coated aluminum plate 5 from top to bottom. Composite with five layers, the mirror aluminum plate 1 is a high-gloss mirror aluminum with a total reflectance as high as 87% or a semi-mirror aluminum with mirror and matt aluminum oxide effects on the surface. The thickness of the aluminum plate is 0.1-0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com