An electrolytic manganese slag black glass decoration material and method of producing the same

A technology of electrolytic manganese slag and black glass, applied in the field of black glass decorative materials, can solve the problems of difficult control of doping accuracy, difficulty in applying decorative materials, and weak invention pertinence, etc., achieve good decorative effects and shorten production cycle , is conducive to the effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

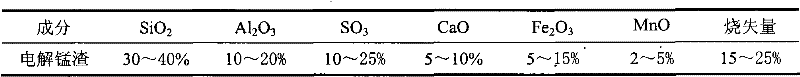

[0027] The raw material composition and mass percent of a kind of electrolytic manganese slag black glass decoration material are:

[0028] Electrolytic manganese slag: 91.5%

[0029] Sodium carbonate: 8%

[0031] The concrete steps of a kind of preparation method of electrolytic manganese slag black glass decorative material are as follows:

[0032] (1) material preparation

[0033] By electrolytic manganese slag: sodium carbonate: the ratio of mass percent of charcoal powder is 91.5%: 8%: 0.5%, the raw material of glass melt is prepared, and electrolytic manganese slag and sodium carbonate and charcoal powder are mixed and stirred evenly, A raw material mixture for a glass melt is prepared.

[0034] (2) Melting and clarification of the melt

[0035] After step (1) is completed, put the raw material mixture of the glass melt prepared in step (1) into a melting furnace for melting. The melting temperature is 1200°C, and the melting and clar...

Embodiment 2

[0039] The raw material composition and mass percent of a kind of electrolytic manganese slag black glass decoration material are:

[0040] Electrolytic manganese slag: 98.4%

[0041] Sodium carbonate: 0.1%

[0043] The concrete steps of a kind of production method of electrolytic manganese slag black glass decorative material are as follows:

[0044] (1) material preparation

[0045] With embodiment 1, wherein: the ratio of the mass percent of electrolytic manganese slag: sodium carbonate: charcoal powder is 98.4%: 0.1%: 1.5%.

[0046] (2) Melting and clarification of the melt

[0047] Same as Example 1, wherein: the melting temperature is 1250° C., and the melting and clarification time is 30 minutes.

[0048] (3) Melt forming and annealing

[0049] Same as Example 1, wherein: the annealing temperature is 650° C., the annealing time is 60 minutes, the annealing cooling rate is 20° C. / min, and the temperature drops to 320° C.

Embodiment 3

[0051] The raw material composition and mass percent of a kind of electrolytic manganese slag black glass decoration material are:

[0052] Electrolytic manganese slag: 89%

[0053] Sodium carbonate: 10%

[0055] The concrete steps of a kind of production method of electrolytic manganese slag black glass decorative material are as follows:

[0056] (1) material preparation

[0057] With embodiment 1, wherein: electrolytic manganese slag: sodium carbonate: the ratio of the mass percent of charcoal powder is 89%: 10%: 1%.

[0058] (2) Melting and clarification of the melt

[0059] Same as Example 1, wherein: the melting temperature is 1150° C., and the melting and clarification time is 60 minutes.

[0060] (3) Melt forming and annealing

[0061] Same as Example 1, wherein: the annealing temperature is 670° C., the annealing time is 70 minutes, the annealing cooling rate is 25° C. / min, and the temperature drops to 300° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com