Method for preparing titanium dioxide-supported noble metal visible light material

A photocatalytic material, titanium dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficult to control the uniform distribution of noble metal nanoparticles, and achieve The effect of highly efficient selective photooxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

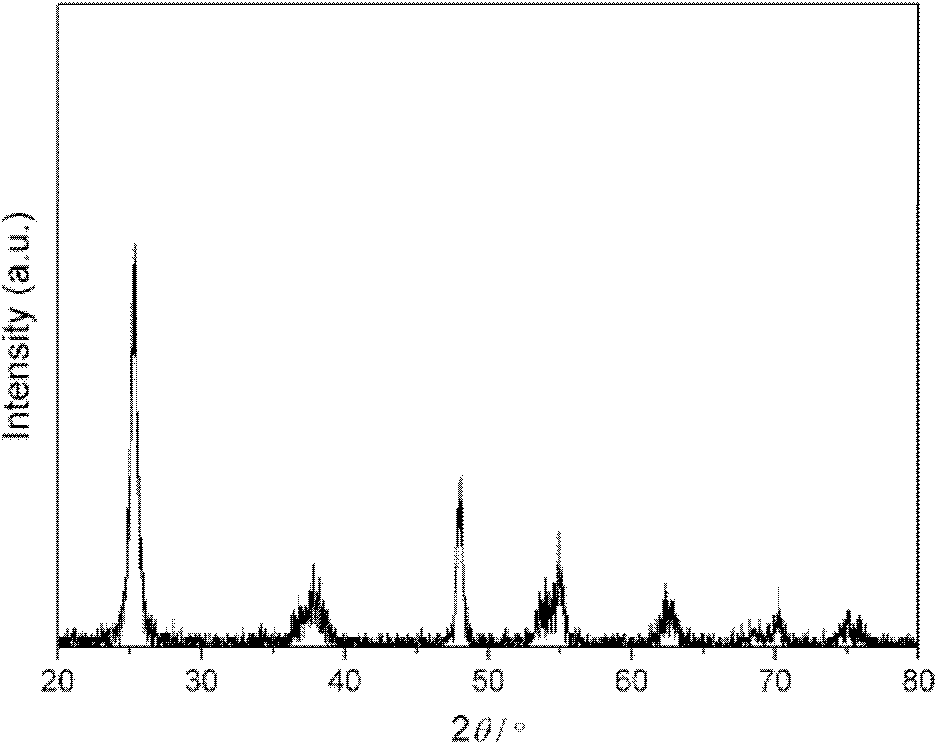

[0021] In this example, titanium dioxide microspheres were selected as the carrier. Mix tetrabutyl titanate and ethanol uniformly at a volume ratio of 1:4, and add 40% hydrofluoric acid solution: wherein the volume ratio of tetrabutyl titanate and hydrofluoric acid solution is 25:3. Put the mixed solution into an autoclave lined with polytetrafluoroethylene, and react at 180°C for 2 hours. After natural cooling, the product is washed, filtered, and dried to obtain anatase phase titanium dioxide with a diameter of 3-6 μm. Microspheres.

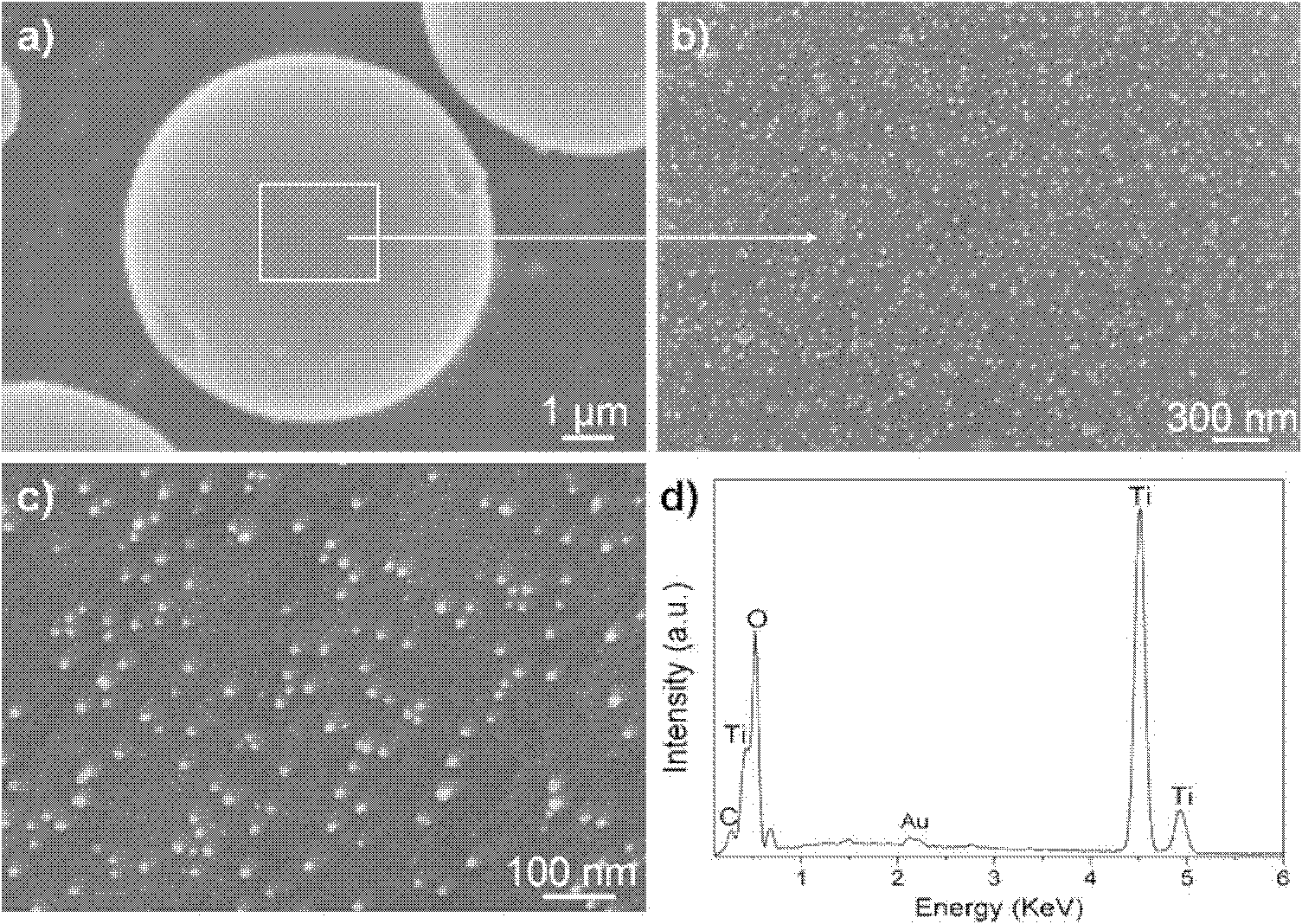

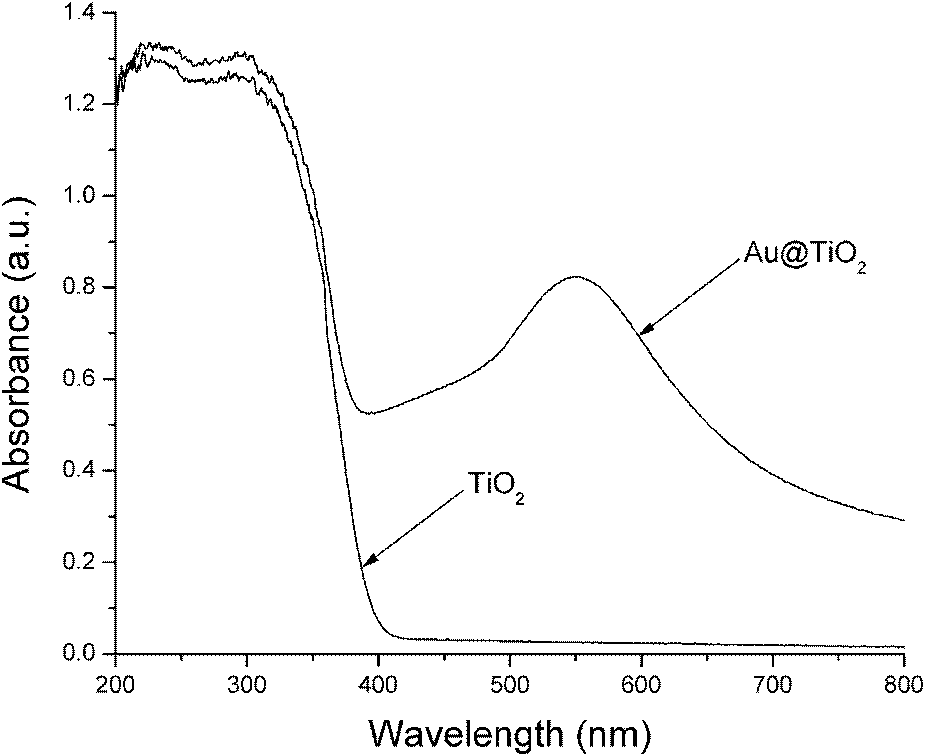

[0022] Add 1g of titanium dioxide microspheres into 50mL of absolute ethanol to form a suspension, feed nitrogen, and irradiate with ultraviolet light for 3min under anaerobic conditions, and then inject 1wt% of chloroauric acid into the suspension in the dark. 3+ Under the reduction of the metal ions, the metal ions are converted into elemental metal nanoparticles and deposited on the surface of titanium dioxide, thus forming AuTiO 2 Visible...

Embodiment 2

[0025] In this example, titanium dioxide microspheres were selected as the carrier. Mix tetrabutyl titanate and ethanol uniformly at a volume ratio of 1:5, and add 40% hydrofluoric acid solution: wherein the volume ratio of tetrabutyl titanate to hydrofluoric acid solution is 25:3. Put the mixed solution into an autoclave lined with polytetrafluoroethylene, and react at 160°C for 2 hours. After natural cooling, the product is washed, filtered, and dried to obtain anatase phase titanium dioxide with a diameter of 3-5 μm. Microspheres.

[0026] Add 0.5g of titanium dioxide microspheres into 50mL to form a suspension, feed nitrogen, and irradiate with ultraviolet light for 10min under anaerobic conditions, then inject a certain amount of (1wt%) chloroplatinic acid into the suspension in the dark. Ti 3+ Under the reduction of the metal ions, the metal ions are converted into elemental metal nanoparticles and deposited on the surface of titanium dioxide, thus forming PtTiO 2 Vis...

Embodiment 3

[0028] In this example, titanium dioxide microspheres were selected as the carrier. Mix tetrabutyl titanate and ethanol uniformly at a volume ratio of 1:4, and add 40% hydrofluoric acid solution: wherein the volume ratio of tetrabutyl titanate and hydrofluoric acid solution is 25:3. Put the mixed solution into an autoclave lined with polytetrafluoroethylene, and react at 170°C for 2 hours. After natural cooling, the product is washed, filtered, and dried to obtain anatase phase titanium dioxide with a diameter of 3-6 μm. Microspheres.

[0029] Add 0.5g of titanium dioxide microspheres to 50mL of absolute ethanol to form a suspension, feed nitrogen, and irradiate with ultraviolet light for 5min under anaerobic conditions, then inject a certain amount (1wt%) of silver nitrate into the suspension in the dark , at Ti 3+ Under the reduction of the metal ions, the metal ions are converted into elemental metal nanoparticles and deposited on the surface of titanium dioxide, thus for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com