Manual implementation method for manufacturing technology of thin film solar cell

A solar cell and manufacturing process technology, applied in the process field, can solve problems such as time-consuming and labor-intensive, time-consuming and labor-intensive, hindering the efficiency and flexibility of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The system and method of the present invention will be better understood with reference to the drawings and description. For non-specific and non-limiting embodiments, please refer to the description of the accompanying drawings. The constituent elements in the drawings are not necessarily to scale, emphasis instead being placed upon illustrating the principles of the invention. In the drawings, the same elements have the same corresponding parts in different drawings.

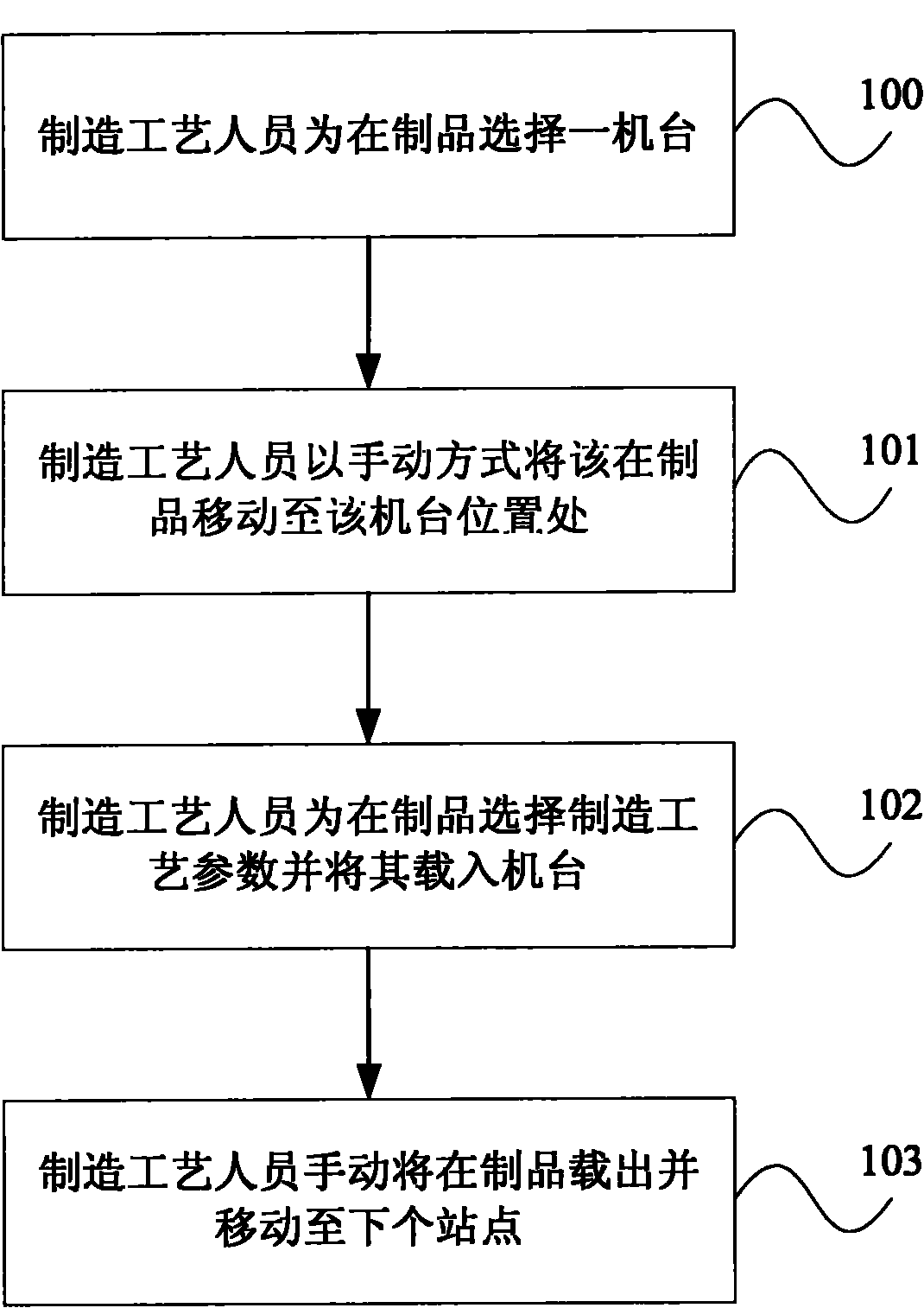

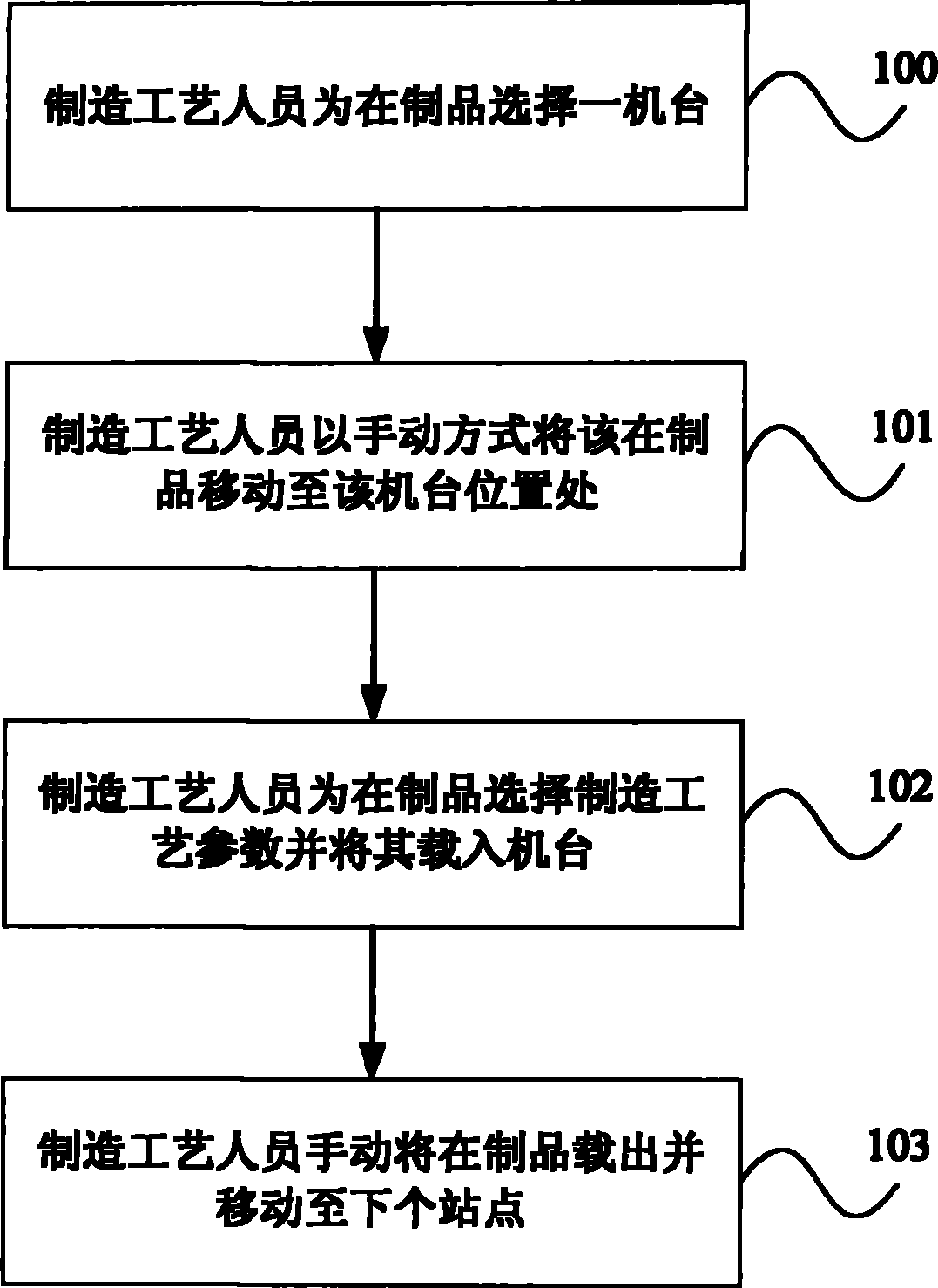

[0017] Please refer to figure 1 , which is a flow chart of the steps of the manual execution method of the manufacturing process of the present invention. Firstly, in step 100, instead of using the usual method of automatically assigning machines by the system, a manufacturing technician selects a machine for the work-in-progress to carry out the manufacturing process. The selection of the machine is based on the manufacturing process Personnel judge and make decisions on the situation of each machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com