Positioning fixture and manufacturing process machine

A technology for positioning fixtures and manufacturing processes, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of silicon chip damage, production process yield decline, etc., to avoid damage, improve production process yield, The effect of good production process elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

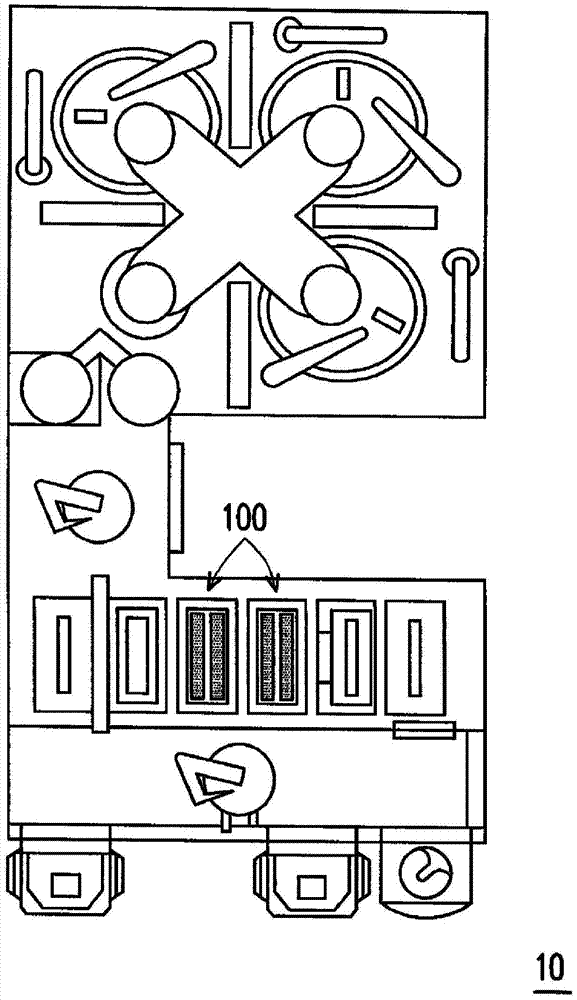

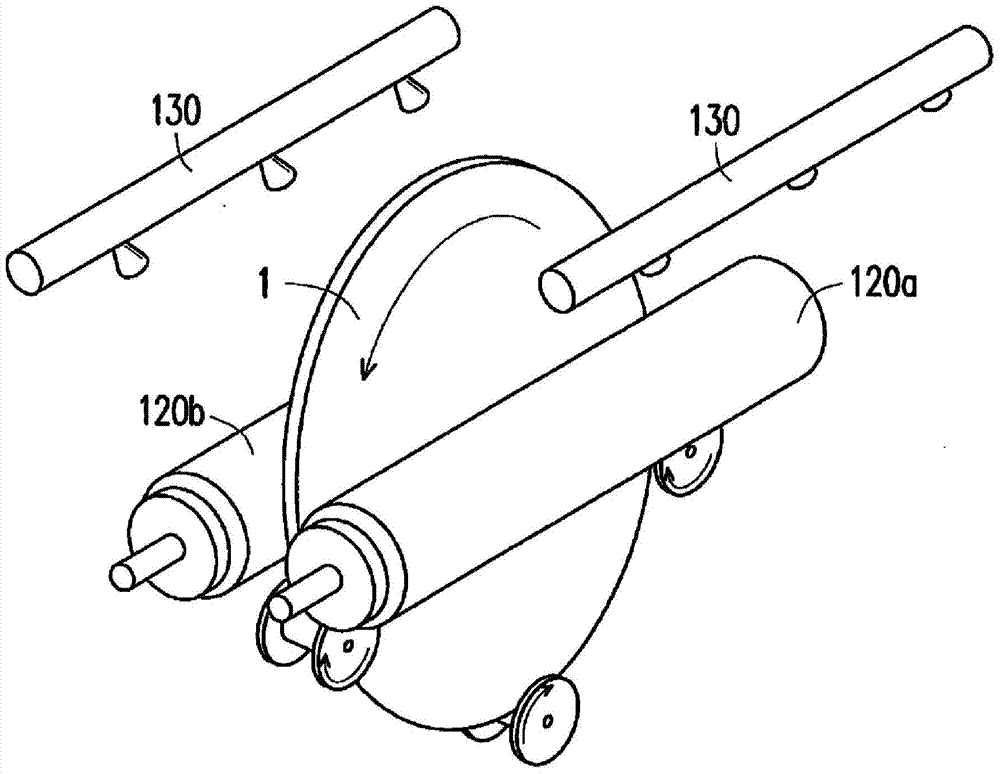

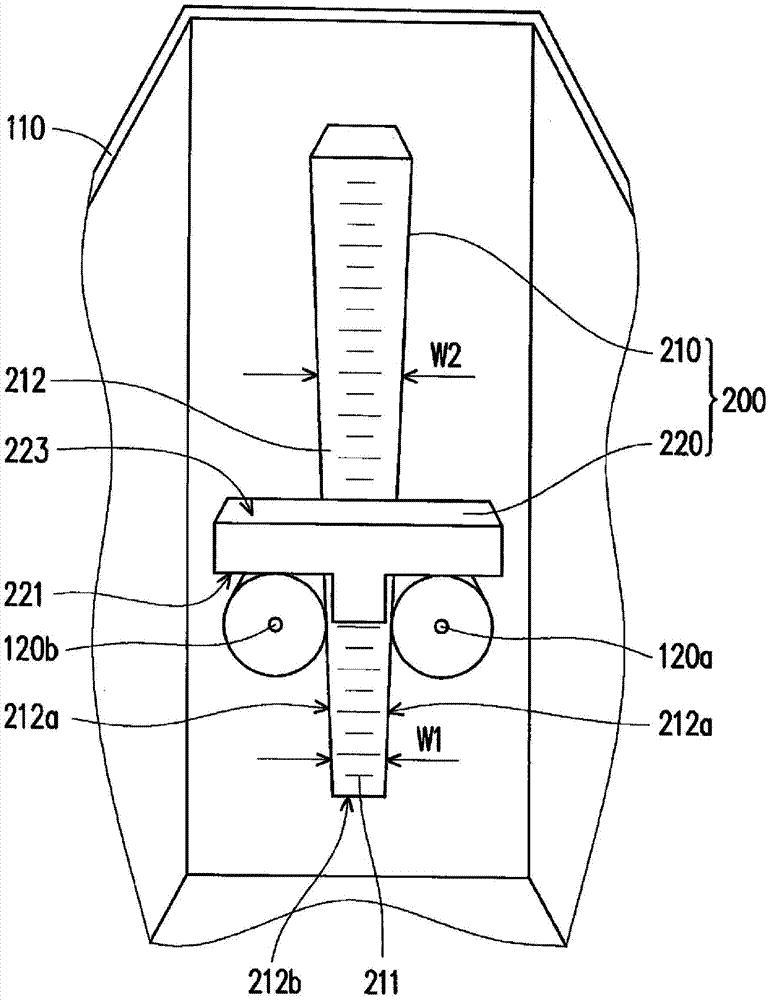

[0046] Figure 1A It is a schematic diagram of a manufacturing process machine according to an embodiment of the present invention. Figure 1B Yes Figure 1A Schematic diagram of the production process equipment for chemical mechanical polishing. figure 2 Yes Figure 1A Schematic diagram of the manufacturing process equipment and the positioning jig applied to this manufacturing process equipment, in order to clearly show and explain, figure 2 The adjustment mechanism 140 is omitted. Please refer to Figure 1A , Figure 1B versus figure 2 In this embodiment, the manufacturing process machine 10 includes a manufacturing process equipment 100 and a positioning jig 200, wherein the manufacturing process equipment 100 is, for example, a chemical mechanical polishing equipment applied to a semiconductor manufacturing process, but the present invention is not limited thereto.

[0047] The manufacturing process equipment 100 includes a container 110, a first scrubbing member 120a, and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com