Method for predicting service life of hot carrier of silicon on insulator (SOI) device

A silicon-on-insulator and hot-carrier technology, which is applied to the testing of a single semiconductor device, can solve the problems of inaccurate, different, and no self-heating effects of hot-carrier life, and achieve the elimination of self-heating effects, accurate prediction, Predict accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

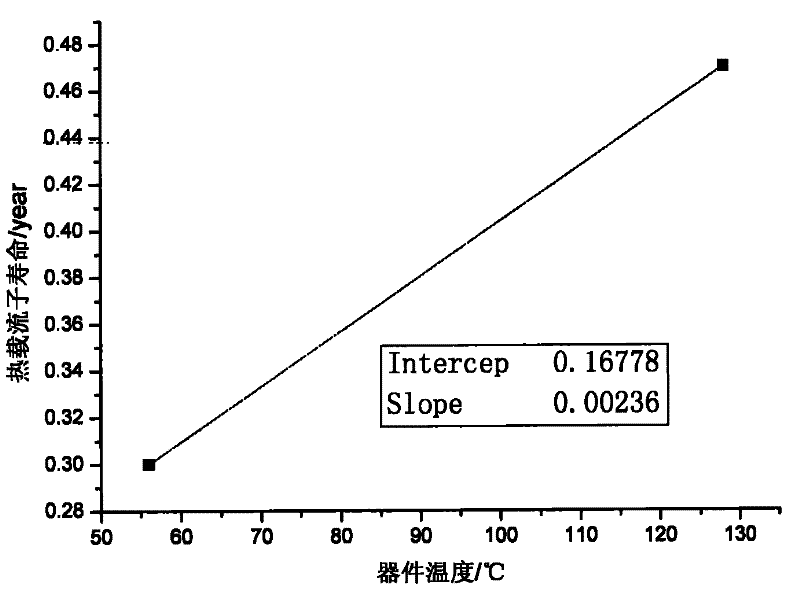

[0031] Firstly, the thermal resistance of SOI NMOS with a width-to-length ratio of 10 / 0.35 is extracted by using the source-body PN junction diode current as a temperature sensor, and its value is 0.0344m℃ / W. Then after testing at 25°C and 100°C, the stress condition is leakage voltage V d =3.9V, gate voltage V g = Drain current at 1.65V (the stress condition is determined by the maximum substrate current method), and calculate the device power, and then calculate the actual temperature of the device according to the thermal resistance to be 56°C and 128°C respectively.

[0032] Then select three 10 / 0.35 NMOS for accelerated stress experiment, the stress condition is V d =3.9V, V g =1.65V, the time is 5000s, and the ambient temperature is 25°C and 100°C. Then use the substrate / drain current ratio model to predict the lifetime. The hot carrier lifetime of the device at an ambient temperature of 25°C and 100°C is 0.3 years and 0.47 years, respectively, that is to say, the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com