Method for reinforcing soft broken coal rock by directional grouting

A technology of crushing coal rocks and grouting reinforcement, which is applied in earthwork drilling, shaft lining, tunnel lining, etc. It can solve the problems of slurry waste, difficult mining, and increased mining costs, and achieves low cost, saving consumption, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

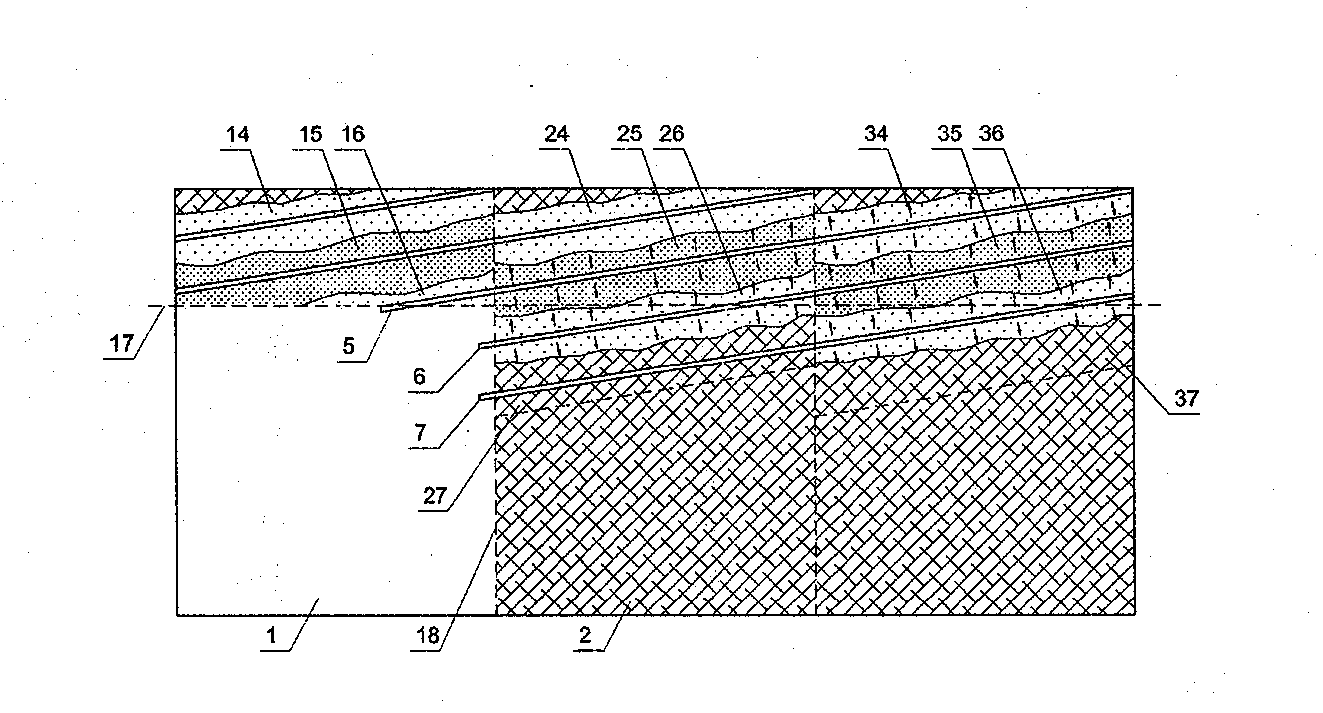

[0024] Embodiment one: see figure 1 , figure 2 ,, the number 1 in the figure is the mined section, 2 is the pre-mined section, 11 is the upper layer grouting pipe of the mined section, 14 is the upper fixed section of the mined section, 15 is the middle fixed section of the mined section, 21 is The upper layer grouting pipe of the pre-mining section, 22 is the middle layer grouting pipe of the pre-mining section, 23 is the lower layer grouting pipe of the pre-mining section, 24 is the upper reinforcement section of the pre-mining section, and 25 is the middle layer reinforcement section of the pre-mining section , 26 is the lower layer reinforcement section of the pre-mined section, 34 is the upper layer reinforcement section of the unmined section, 35 is the middle layer reinforcement section of the unmined section, 36 is the lower layer reinforcement section of the unmined section, 17 is the top of the mining face, and 18 is the mining surface Face end face, and 20 are slu...

Embodiment 2

[0028] Embodiment two: see image 3 , Figure 4 , the labels are the same as those in Embodiment 1, and will not be repeated. The reinforcement method of this embodiment is to excavate pits upwards at the top of the mined area close to the mining face to form a drilling work area 19, divide the vertical area where the pits are located as the upper fixed section, and mine along the end face of this section. Drill holes in different directions; from the upper fixed section downwards, it is divided into a middle fixed section and a lower fixed section, and holes are drilled at the end faces of the middle fixed section and the lower fixed section in the mining direction; the insertion length in each drill hole is not less than d The constant-pressure grouting pipes with holes are used to inject reinforcement grout into each constant-pressure grouting pipe. Among them, the cost performance of reinforcement grout A in the upper and lower reinforcement sections is lower than that of...

Embodiment 3

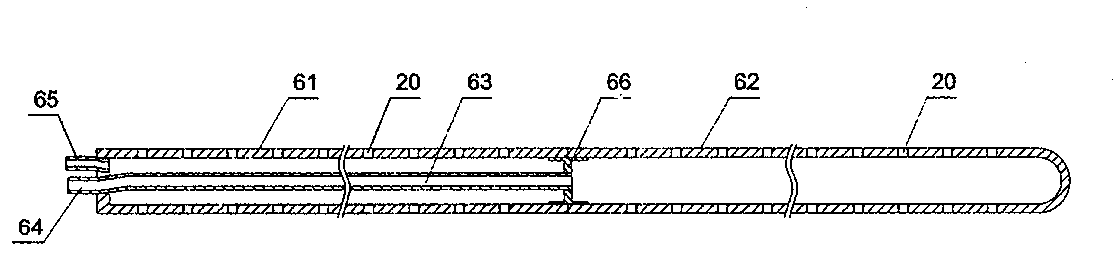

[0030] Embodiment three: see Figure 5 , Figure 6 , Figure 7 , label is the same as embodiment one, does not repeat, increases label 5 and is the subsection grouting pipe of middle and upper layer, and 6 is the subsection grouting pipe of middle and lower floor, and 7 is that only inner section has grouting hole (length is d ) grouting pipe, pre-mined virtual section 27, and unmined virtual section 37.

[0031] The reinforcement method of this embodiment is, on the upper part of the mining face, divide the upper layer fixed section, the middle layer fixed section, the lower layer fixed section and the virtual section 27 respectively from top to bottom; The section is drilled upwards inclined to the horizontal plane, and the length of the drilling hole is not less than 2d. Segmented grouting pipes with holes are respectively inserted into the boreholes of the middle fixed section and the lower fixed section of the pre-mining section. See Figure 6 , each segmented grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com