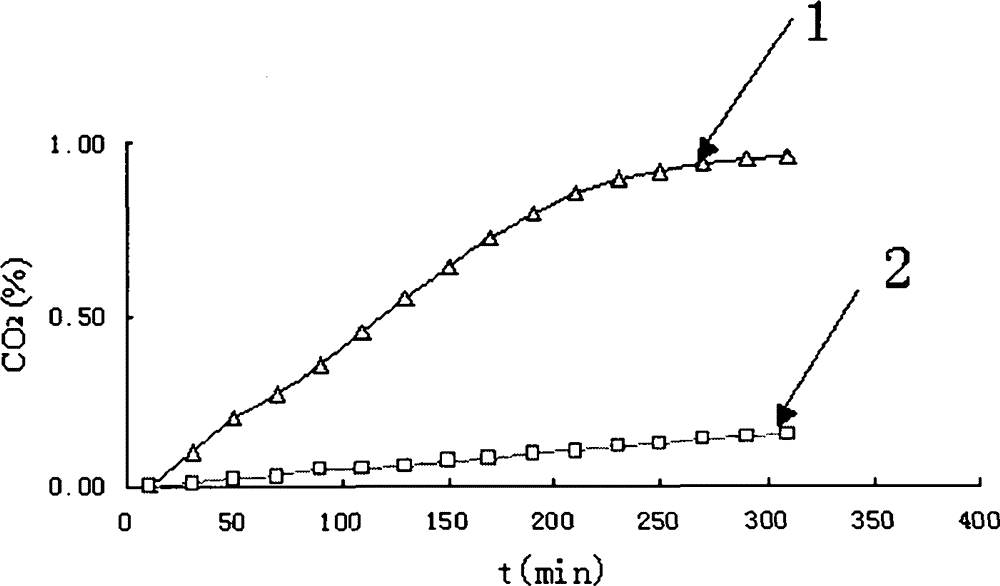

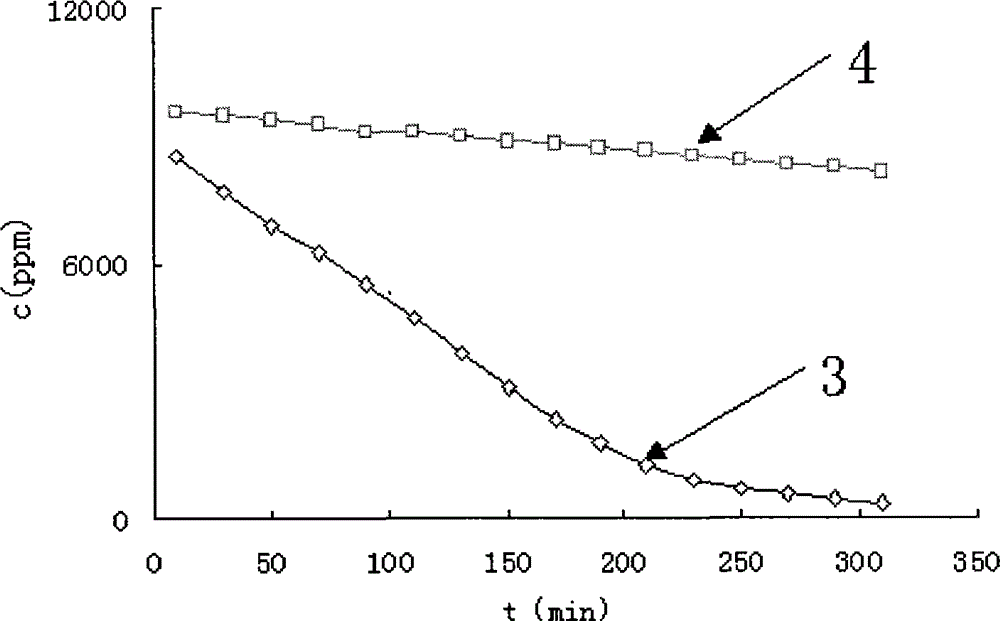

A latex paint that can absorb carbon dioxide

A technology of carbon dioxide and latex paint, applied in the field of interior wall latex paint, can solve the problems of affecting the leveling performance of latex paint, coarsening of latex paint particles, poor dispersion performance, etc., and achieve good leveling of the coating film, good fluidity, Effect of small change in viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

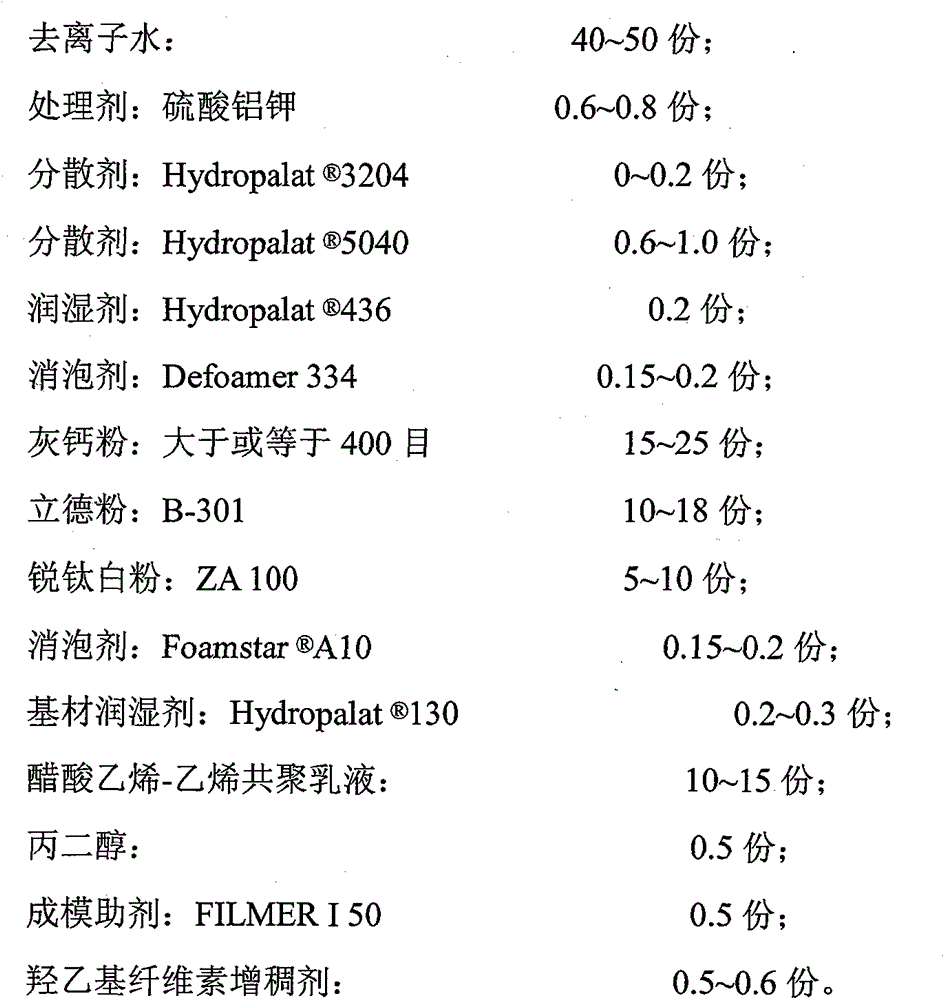

Embodiment 1

[0045] Pulping stage: add 20 parts of deionized water, 0.6 parts of potassium aluminum sulfate (treatment agent), and the model is Hydropalat 0.2 parts of 3204 chelating dispersant, model Hydropalat 0.6 parts of 5040 sodium polycarboxylate dispersant, model Hydropalat After 0.2 part of 436 wetting agent and 0.15 part of defoamer of model Defoamer 334, disperse at low speed (500rpm~800rpm), then add 15 parts of gray calcium powder above 400 mesh and disperse at low speed (500rpm~800rpm) In this case, pretreat the powder for half an hour, then add 18 parts of Lithopone of model B-301 and 10 parts of anatase of model ZA 100, and disperse at a low speed (500rpm~800rpm) for 10 minutes. The added lithopone and anatase are wetted, followed by high-speed dispersion (2000rpm) for 20 minutes, then sanding for 30 minutes at 3000rpm, and finally filtering according to the standard of fineness less than 40μm.

[0046] Paint let-down stage: For the slurry made in the pulping stage, the model...

Embodiment 2

[0052] Add 20 parts of deionized water, 0.8 parts of potassium aluminum sulfate (treatment agent), and the model is Hydropalat 0 parts of 3204 chelating dispersant, model Hydropalat 1.0 part of 5040 sodium polycarboxylate dispersant, model Hydropalat After 0.2 part of 436 wetting agent and 0.2 part of defoamer of model Defoamer 334, disperse at low speed (500rpm~800rpm) until uniformly mixed, add 25 parts of gray calcium powder above 400 mesh, and perform 30 minutes of gray calcium powder Low-speed dispersion pretreatment; add 10 parts of Lithopone and 5 parts of anatase, then perform high-speed dispersion treatment for 20 minutes, and then sand the mixture at high speed for 30 minutes until the fineness is less than 40μm, and filter the mixture to obtain Slurry.

[0053] Add Foamstar to the prepared slurry A10 defoaming agent 0.15 parts for 10 minutes low-speed defoaming, and then followed by low-speed dispersion to add 0.3 parts of the substrate wetting agent, 15 parts of vi...

Embodiment 3

[0059] Add 20 parts of deionized water, 0.7 parts of aluminum potassium sulfate (treatment agent), and the model is Hydropalat 0.1 part of 3204 chelating dispersant, model Hydropalat 0.9 parts of 5040 sodium polycarboxylate dispersant, model Hydropalat After 0.2 part of 436 wetting agent and 0.15 part of defoamer of model Defoamer 334, disperse at low speed until uniformly mixed, add 20 parts of gray calcium powder above 400 mesh, and perform low-speed dispersion pretreatment on gray calcium powder for 30 minutes Add 15 parts of Lithopone and 5 parts of Anatase for 20 minutes for high-speed dispersion, then 30 minutes for high-speed sanding of the mixture until the fineness is less than 40 μm, and filter the mixture to obtain a slurry.

[0060] Add Foamstar to the prepared slurry A10 defoaming agent 0.2 parts for 10 minutes low-speed defoaming, and then followed by low-speed dispersion to add 0.2 parts of the substrate wetting agent, 10 parts of vinyl acetate-ethylene (VAE) cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com