Process for preparing high-strength, energy-saving, environmentally-friendly and low-viscosity glass

It is an energy-saving, environmental-friendly, and preparation technology, which is applied in photovoltaic power generation, electrical components, circuits, etc., and can solve problems such as increased product strength and complex production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

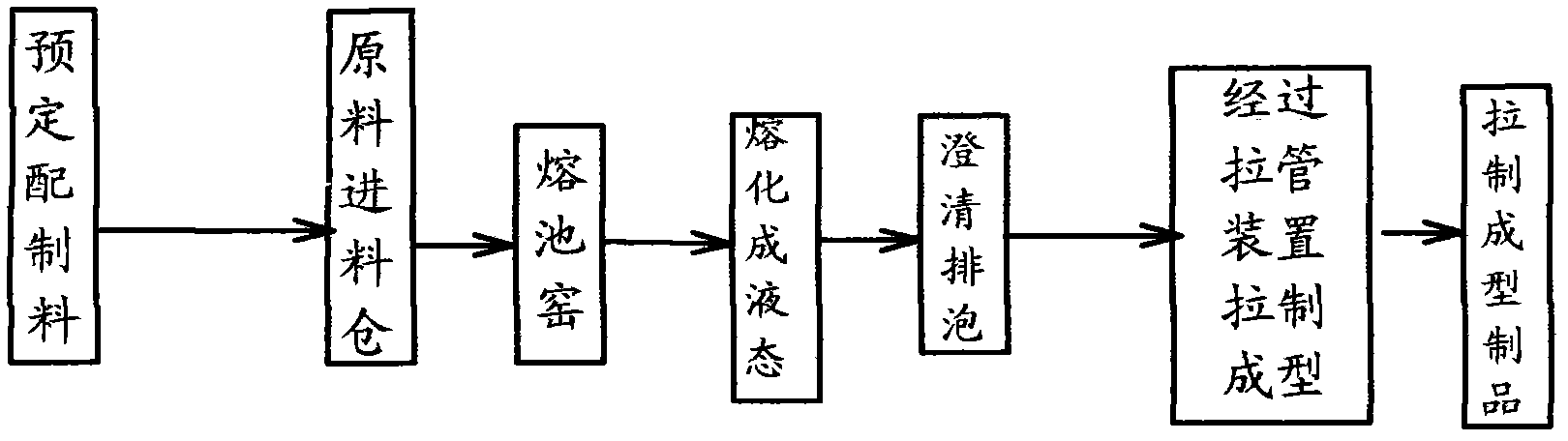

[0046] According to one embodiment of the present invention, a process for preparing high-strength, energy-saving and environmentally friendly low-viscosity characteristic glass comprises the following steps:

[0047] Step 1: According to the composition of silicon oxide, calcium oxide, magnesium oxide, aluminum oxide, iron oxide and sodium oxide in the glass, the content of boron oxide in the glass is 0-1%, and the content of sodium oxide is The content of iron oxide is 0.01-14%, the content of iron oxide is 0.01-5%, the content of fluorine oxide is 0-1%, the content of magnesium oxide is 8.1-20.2%, the content of aluminum oxide is 8-30%, and the content of silicon oxide is oxidized 1.9-4.1 times the content of calcium, 1.2-1.6 times the content of calcium oxide is 1.2-1.6 times the content of magnesium oxide; prepare the raw materials required for making glass according to the above requirements;

[0048] Step 2: Put all kinds of raw materials prepared in their respective ra...

example 1

[0084] On the basis of the above-mentioned first embodiment, by weight percentage, the content of aluminum oxide is 8-30%, silicon oxide: calcium oxide is 2.0-3.6 times, calcium oxide: magnesium oxide is 1.3-1.49 times, sodium oxide is 0.01-2%, boron oxide is 0-1%, fluorine oxide content is 0-1%; the lower limit of the annealing temperature of the glass (that is, the starting temperature of the endothermic peak) is 610°C-680°C; the glass has a viscosity of 10 0.5 (Pa·s) temperature is 1520°C-1640°C; viscosity is 10 1 (Pa·s) temperature is 1450°C-1580°C; viscosity is 10 2 (Pa·s) temperature is 1210°C-1350°C; viscosity is 10 3 (Pa·s) temperature is 1070°C-1230°C; the flexural strength of the glass is 75-180MPa.

example 2

[0086] On the basis of the above-mentioned first embodiment, by weight percentage, the content of aluminum oxide is 19-30%, silicon oxide: calcium oxide is 2.0-3.6 times, calcium oxide: magnesium oxide is 1.3-1.49 times, sodium oxide is 0.01-2%, boron oxide is 0-1%, fluorine oxide content is 0-1%; the lower limit of the annealing temperature of the glass (that is, the starting temperature of the endothermic peak) is 610°C-680°C; the glass has a viscosity of 10 0.5 (Pa·s) temperature is 1550°C-1640°C; viscosity is 10 1 (Pa·s) temperature is 1450°C-1580°C; viscosity is 10 2 (Pa·s) temperature is 1210°C-1350°C; viscosity is 10 3 (Pa·s) temperature is 1080°C-1230°C; the flexural strength of the glass is 130-180MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com