Integrated continuous gas-driving hydraulic force booster

A booster device and gas-liquid booster cylinder technology, which is applied in the hydraulic and pneumatic fields, can solve problems such as low efficiency of the booster cylinder, complex structure of the gas-hydraulic booster cylinder, and inability to realize automatic reversing, and achieve a large booster ratio , compact structure and large boost ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments shown in the drawings.

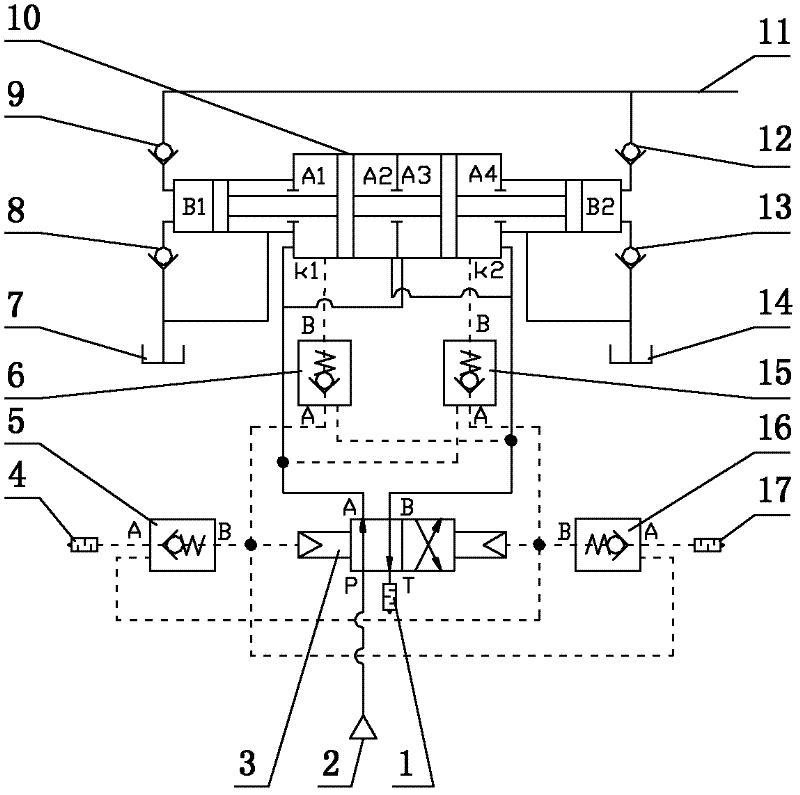

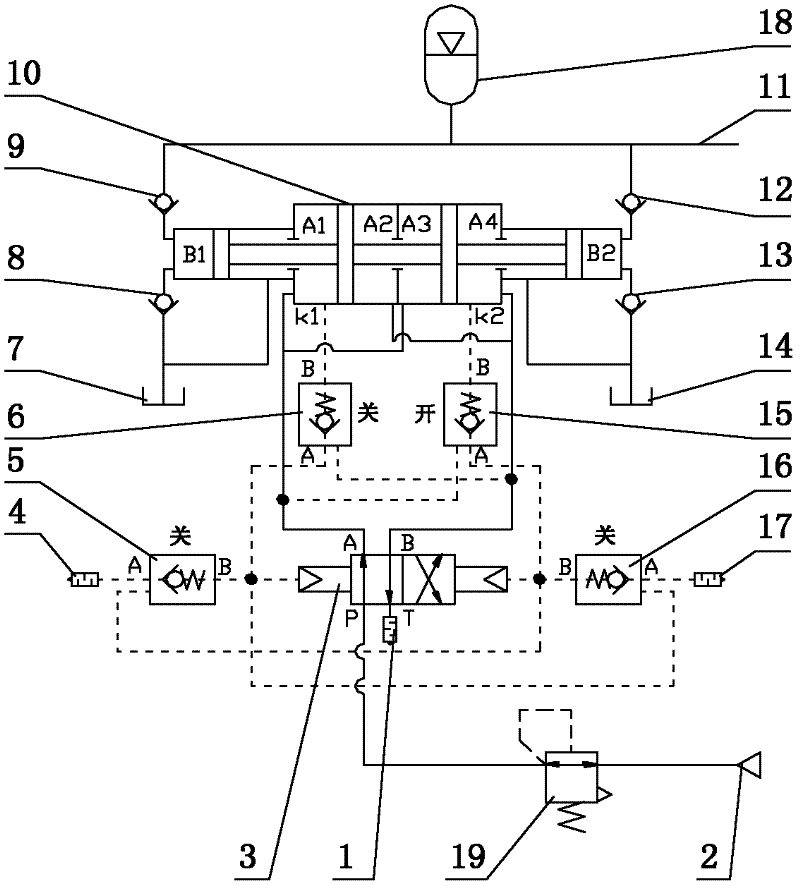

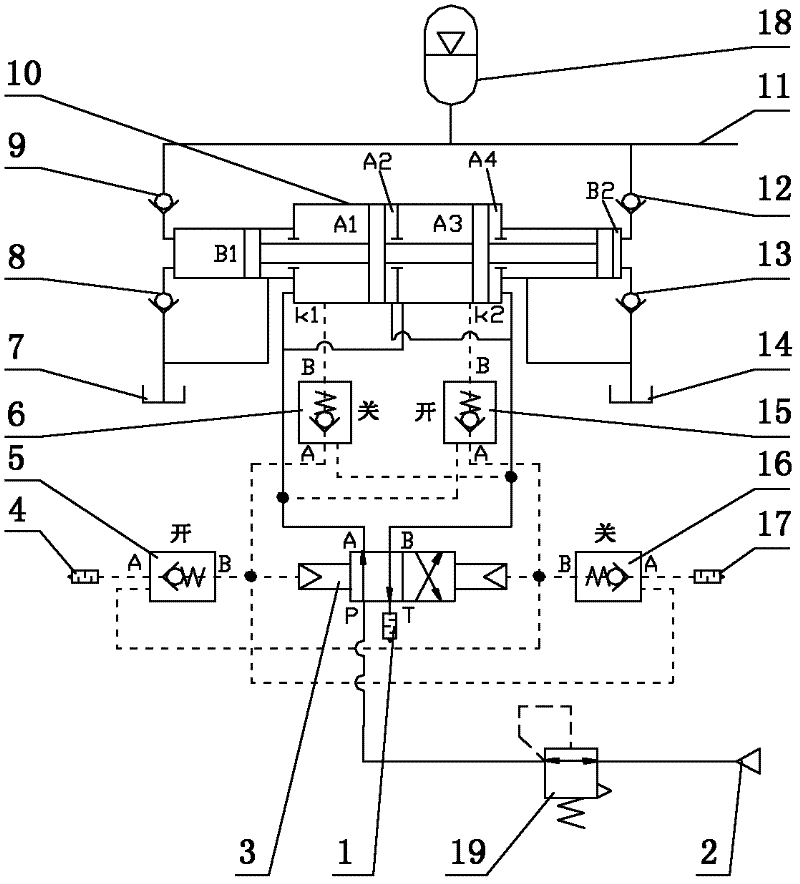

[0025] The connection method of the present invention is: an integrated continuous air-driven hydraulic booster device, consisting of a gas-liquid booster cylinder 10, a hydraulic one-way valve 8, 9, 12, 13, a two-position four-way gas-controlled reversing valve 3, a pneumatic control One-way valves 5, 6, 15, 16, mufflers 1, 4, 17 and so on. Among them, the gas-liquid booster cylinder is a double-acting booster cylinder, and its piston rod is equipped with two large pistons and two small pistons; the two small pistons and the cylinder body form two oil chambers B1 and B2; The piston and the cylinder constitute four air chambers A1, A2, A3, and A4. In the middle of the two air chambers on both sides, there are two stroke signal ports k1, k2. The stroke signal ports k1 and k2 are used to feed back the booster cylinder 10. The stroke information of the piston an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com